CROSSLEY'S INTI PASSENGI rUCE TWO NEW CHASSIS.

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

SINCE the announcement in the issue of The Commercial Motor for July 23rd, 1928, of the Crossley Co.'s entry into the commercial vehicle industry--as distinct from the manufacture of Government-type lorries and tractors—the design department has been busy on development work. An entirely new chassis and an additional Eagle with normal control are now built and ready for almost immediate delivery.

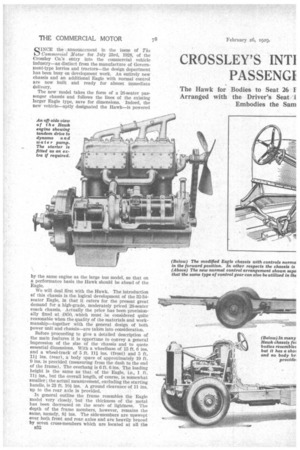

The new model takes the form of a 26-seater passenger chassis and follows the lines of the existing larger Eagle type, save for dimensions. Indeed, the new vehicle—aptly designated the Hawk—is powered • by the same engine as the large bus model, so that on a performance basis the Hawk should be ahead of the Eagle.

We will deal first with the Hawk. The introduction of this chassis is the .logical. development of the 32-34. seater Eagle, in that it caters for the present great demand for a high-grade, moderately priced 26-seater coach chassis. Actually the price has been provisionally fixed at £850, .which must be considered quitereasonable when the quality of the materials and workmanship—together with the general design of both power unit and chassis—are taken into consideration.

Before proceeding to give a detailed description of the main features it is opportune to convey a general Impression of the size of the chassis and to quote essential dimensions. With a wheelbase of 15 ft. 6 ins. and a wheel-track of 5 ft. 111 ins. (front) and 5 ft. 11i ins. (rear), a body space of approximately 19 ft. 9 ins. is provided (measuring from the dash to the end of the frame). The overhang is Oft. Gins. The loading height is the same as that of the Eagle, *i.e., 1 ft. 113-, ins., but the overall length, of course, is somewhat smaller ; the actual measurement, excluding the starting handle, is 23 ft. 1Oi ins. A ground clearance of 11 ins. up to the rear axle is provided.

In general outline the frame resembles the Eagle model very closely, but the thickness of the metal has been decreased on the score a lightness. The depth of the frame members, however, remains the same, namely, 8 iris. The side-Members are upswept over both front and rear axles and are heavily braced by seven cross-members which are located at all the

B32

sion points at the rear of the engine are rigid ; the single point at the front allows for a considerable amount of relative movement, as it is effected through the medium of an ordinary journal bearing which is provided with means for lubrication.

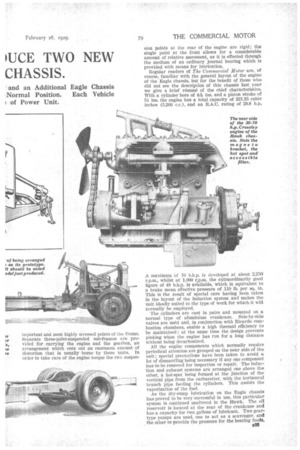

Regular readers of The Commercial Motor are, of course, familiar, with the general layout of the engine of the Eagle Chassis, but for the benefit of those who did not see the description of this chassis last year we give a brief resume of the chief characteristics. With a cylinder bore of 4-Igg ins, and a piston stroke of 51 ins, the engine has a total capacity of 321.35 cubic inches (5,266 c.c.), and an R.A.C. rating of 29.8 h.p.

A maximum Of 70 b.h.p. is developed at about 2,250 r.p.m., whilst at' 1,000 the extraordinarily good figure of 48 b.h.p. is available, which is equivalent to a brake mean effective pressure of 110 lb. per sq. in. This is the result of special care having been taken in the layout of the induction system and makes the unit ideally suited to the type of work for which it will normally be employed.

The cylinders are cast in pairs and mounted on a normal type of aluminium crankcase. Side-by-side valves are used and, in conjunction with Ricardo combustion chambers, enable a high thermal efficiency to be maintained: at the same time the design prevents pinking when the engine has run for a long distance

without being decarbonized. _ All the engine components which normally require periodical attention are grouped on the near side, of the unit ; special precautions have been taken to avoid a. lot of dismantling being necessary if any one component has to be removed for inspection or repair. The induction and exhaust systems are arranged one above the other, a hot-spot being formed at the junction of the vertical pipe from the carburetter, with the horizontal branch pipe feeding the cylinders. This assists the vaporization of the fuel.

As the dry-sump lubrication on the Eagle chassis has proved to be very successful in use, this particular system is continued unaltered in the Flawk. The oil reservoir is located at the rear of the crankcase and has a capacity for two gallons of lubricant. Two geartype pumps are used, one to act as a scavenger, and the other to provide the pressure for the bearing feeds,

adequate filters being incorporated in the various pipelines.

The power is transmitted through a single-plate clutch of large capacity to a separately mounted four:speed gearbox, having the following overall ratios :First gear, 3089 to 1; second, 17.27 to 1; third, 9.87 to 1; and top (direct), 5.25 to 1. The gearbox itself is so planned that by taking off one cover at the rear and withdrawing the sliding shaft, all the gears can be lifted out through another large inspection cover on the top.

A two-stage propeller shaft of the open type is used to transmit the power to a robust, underslung-worm rear axle. The forward shaft is supported at its rear end by a large, self-aligning ball bearing which, of course, takes care of both the axle movement and frame distortion.

The layout of the brake gear follows a simple plan to which prominence has often been given from time to time in the pages of The Commercial Motor. Only Cue cross-half is employed for operating both front and rear brakes, a rod from the pedal exerting a straight pull on to a Dewandre servo motor bolted direct to the outside of the frame. The power rod from the rear of the servo communicates with a swinging link mounted on the cross-shaft, from which the actual operating rods emerge.

Mention must be made of the steering. Unlike most normal-control chassis, the steering box is fitted in the

forward position (similar to that occupied ISY the box when forward control is used), and the drag link, in consequence, is located in front of the axle. There are many advantages to be gained by this method of construction. First, the drag link is out of the way of the off-side wheel when it is pulled right over, and in consequence enables a very good steeringlock to be obtained. Secondly, the rake of the steering column is such that perfect freedom of movement is given to the accelerator, clutch and brake pedals, whilst in addition the wheel is brought into a comfortable position for the driver. The actual steering mechanism on the Crossley Hawk is of the cam-and-lever type, the box being equipped with double ball-bearing thrusts.

The capacity of the petrol tank, which by the way is mounted on the near side of the frame, is 35i gallons, the carburetter being fed through the medium of an Autovac. The price of £850 includes a complete set of Dunlop pneumatic tyres of 36-in. by 6-in. section.

Having dealt with the new Hawk chassis in full, it is hardly necessary to say a great deal concerning Oa normal-control Eagle chassis, as the layout of the main features of this vehicle, with the exception or the steering and the dutch and brake controls, is identical with the existing forward-control model. Further, the description of the Hawk control gear is applicable to the Eagle chassis as well. The price of the new normal-type chassis is £945, as compared with £970 for the forward-control design.