Webbing controls the load...

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

SO FAR in this series on loads, the emphasis has been on the dangers of careless loading and the use of unsuitable materials and equipment. in this final article, a more modern approach to securing loads is to be discussed.

Although chains and ropes are useful in many cases, it is difficult to know just how much longer they are going to last without failing, and they can so easily be lost, or for that matter, stolen. And, if ropes get wet, they can be the very devil to loosen, especially if they have been strained by the slight movement of the goods.

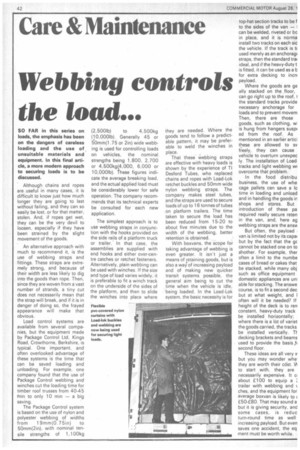

An alternative approach with much to recommend it, is the use of webbing straps and fittings. These straps are extremely strong, and because of their width are less likely to dig into the goods than rope. Then, since they are woven from a vast number of strands, a tiny cut does not necessarily mean that the strap will break, and if it is in danger of doing so, the frayed appearance will make that obvious.

Load control systems are available from several companies, but the equipment made by Package Control Ltd, Kings Road, Crowthorne, Berkshire, is typical. One important, and often overlooked advantage of these systems is the time that can be saved loading and unloading. For example, one company found that the use of Package Control webbing and winches cut the loading time for timber roof trusses from 40-45 Min to only 10 min — a big saving.

The Package Control system is based on the use of nylon and polyester webbing of widths from 19mm(0.75in) to 50rnm(2in), with nominal tensile strengths of 1,100kg (2,5001b) to 4, 500kg (10,0001b). Generally 45 or EiOrrim(1.75 or 2in) wide webbing is used for controlling loads on vehicles, the nominal strengths being 1,800, 2,700 or 4,500kg(4,000, 6,000 or 10,0001b). These figures indicate the average breaking load, and the actual applied load must be considerably lower for safe operation. The company recommends that its technical experts be consulted for • each new application.

The simplest approach is to use webbing straps in conjunction with the hooks provided on the side rails of a platform truck or trailer. In that case, the assemblies are supplied with end hooks and either over-centre catches or ratchet fasteners. Alternatively, plain webbing can be used with winches. If the size and type of load varies widely, it is preferable to fit a winch track on the underside of the sides of the platform, and then to slide the winches into place where they are needed. Where the goods tend to follow a predictable pattern, it may be preferable to weld the winc.hes in place. _ .

That these webbing straps are effective with heavy loads is shown by the experience of T1 Desford Tubes, who replaced chains and ropes with Load-Lok ratchet buckles and 50mm wide nylon webbing straps. The company makes steel tubes, and the straps are used to secure loads of up to 16 tonnes of tubes on platform trailers. The time taken to secure the load has been reduced from 15-20 to about five minutes due to the width of the webbing, better retention is obtained.

With boxvans, the scope for taking advantage of webbing is even greater. It isn't just a means of retaining goods, but is also a way of increasing payload and of making new quicker transit systems possible, the general aim being to cut the time when the vehicle is idle, being loaded. In the Load-Lok system, the basic necessity is for

top-hat section tracks to be f to the sides of the van — 1 can be welded, riveted or be in place, and it is norrna install two tracks on each sid the vehicle. If the track is t< used merely as an anchorag{ straps, then the standard trai ideal, and if the heavy-duty t is fitted, it can be used as a b for extra decking to incr( payload.

Where the goods are ge ally stacked on the floor, can go right up to the roof, I the standard tracks provide necessary anchorage for loads and to prevent movem Then, there are those goods, such as clothing, wl is hung from hangers susp ed from the roof. As mentioned in an earlier articl these are allowed to sv freely, they can cause vehicle to overturn unexpec ly. The installation of Load. tracks and light webbing w{ overcome that problem.

In the food distribu business, the use of whe. cage pallets can save a Co time in loading and unload and in handling the goods in shops and stores. But introduction of these pa required really secure reten in the van, and, here ag webbing straps are the anssn But often, the payload I van is limited not by its capai but by the fact that the gc cannot be stacked one on to abother. For example, ther often a limit to the numbe cases of bread or cakes that be stacked, while many obj such as office equipment domestic appliances are um able for stacking. The ansvve course, is to fit a second dec but at what weight, and I often will it be needed? If height of the deck is to ren constant, heavy-duty track be installed horizontally; where there is a lot of varlet the goods carried, the tracks be installed vertically. Tf decking brackets and beams used to provide the basis second floor.

These ideas are all very v but you may wonder whe. they are worth their cOst. V1 to start with, they are necessarily expensive. It ci about -£100 to equip a trailer with webbing and ches, and the equipment for average boxvan is likely to { £50-£80. That may sound a but it is giving security, and some cases, is reduc turn-round time as well increasing payload. But even saves one accident, the eq rnent must be worth while.