DRIVE FC 1-TONNER

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

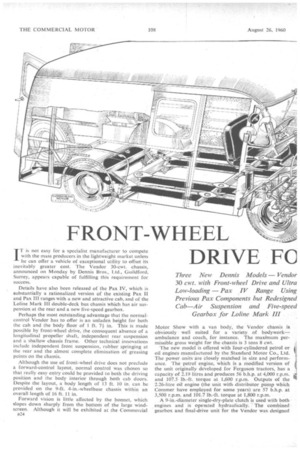

IT is not easy for a specialist manufacturer to compete with the mass producers in the lightweight market unless he can offer a vehicle of exceptional utility to offset its inevitably greater cost. The Vendor 30-cwt. chassis, announced on Monday by Dennis Bros.. Ltd., Guildford, Surrey, appears capable of fulfilling this requirement for success.

Details have also been released of the Pax IV, which is substantially a rationalized version of the existing Pax II and Pax III ranges with a new and attractive cab, and of the Loline Mark III double-deck bus chassis which has air suspension at the rear and a new five-speed gearbox.

Perhaps the most outstanding advantage that the normalcontrol Vendor has to offer is an unladen height for both the cab and the body floor of 1 ft. 7+ in. This is made possible by front-wheel drive, the consequent absence of a longitudinal propeller shaft, independent rear suspension and a shallow chassis frame. Other technical innovations include independent front suspension, rubber springing at the rear and the almost complete elimination of greasing points on the chassis.

Although the use of front-wheel drive does not preclude a forward-control layout, normal control was chosen so that really easy entry could be provided to both the driving position and the body interior through both cab doors. Despite the layout, a body length of 13 ft. 10 in. can be provided on the 9-ft. 4-in.-wheelbase chassis within an overall length of 16 ft. 11 in.

Forward vision is little affected by the bonnet, which slopes down sharply from the bottom of the large windscreen. Although it will be exhibited at the Commercial B24 Motor Show with a van body, the Vendor chassis is obviously well suited for a variety of bodywork— ambulance and coach, for instance. The maximum permissible gross weight for the chassis is 3 tons 8 cwt.

The new model is offered with four-cylindered petrol or oil engines manufactured by the Standard Motor Co., Ltd. The power units are closely matched in size and performance. The petrol engine, which is a modified version of the unit originallydeveloped for Ferguson tractors, has a capacity of 2.19 litres and produces 56 b.h.p. at 4,000 r.p.m. and 107.5 lb.-ft. torque at 1,600 r.p.m. Outputs of the 2.26-litre oil engine (the unit with distributor pump which Commer have employed for some years) 'are 57 b.h.p. at 3,500 r.p.m. and 101.7 lb.-ft. torque at 1,800 r.p.m.

A 9-in.-diameter single-dry-plate clutch is used with both engines and is ope7ated hydraulically. The combined gearbox and final-drive unit for the Vendor was designed and produced by Dennis, as no suitable proprietary transmission was available in this country or on the Continent.

The final-drive assembly is housed in the forward portion of the gearbox casing. The input shaft passes above it to the gearbox, which is a three-speedand-reverse unit with Porsche synchronizers on the three forward gears and constant-mesh engagement for reverse gear. Apart from one lighter van, the Vendor is the first British commercial vehicle to have a synchronized first gear The gearbox output shaft drives into the back of the Salisbury differential unit through spiralbevel reduction gearing. With each engine the final-drive ratio is 5.625 to 1, and the gearbox ratios are 4.071, 2.087 and 1,182 to 1. Reverse ratio is 4.07 to 1. Maximum speeds in the gears with the petrol engine are 16, 31 and 54 m.p.h., whilst the governed speed of the oil engine permits gear speeds of 14, 27 and 48 mph.

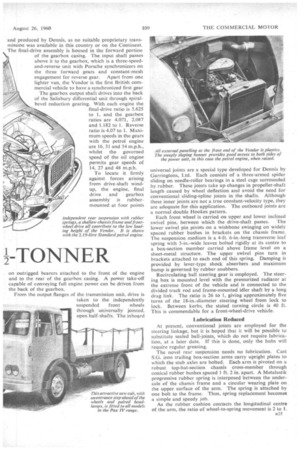

To locate it firmly against forces arising from drive-shaft windup, the engine, final drive and gearbox assembly is rubbermounted at four points Independent rear suspension with rubber springs, a shallow chassis frame and frontwheel drive all contribute to the low loading height of the Vendor. It is shown with the 2.19-litre Standard petrol engine. universal joints are a special type developed for Dennis by Garringtons, Ltd. Each consists of a three-armed spider sliding on needle-roller bearings in a steel cage surrounded by rubber. These joints take up changes in propeller-shaft length caused by wheel deflection and avoid the need for conventional sliding-Spline joints in the shafts. Although these inner joints are not a true constant-velocity type, they are adequate for This application. The outboard joints are a normal double Hookes pattern.

Each front wheel is carried on upper and lower inclined swivel pins, between which the drive-shaft passes. The lower swivel pin pivots on a wishbone swinging on widely spaced rubber bushes in brackets on the chassis frame. The suspension medium is a 4-ft. 6-in.-long transverse leaf spring with 3-in.-wide leaves bolted rigidly at its centre to a box-section member carried above frame level on a sheet-metal structure. The upper swivel pins turn in brackets attached to each end of this spring. Damping is provided by lever-type shock absorbers and maximum bump is governed by rubber snubbers.

Recirculating ball steering gear is employed. The steer ing box is mounted level with the pressurized radiator at the extreme front of the vehicle and is connected to the divided track rod and frame-mounted idler shaft by a long drag link. The ratio is 26 to 1, giving approximately five turns of the 18-in.-diameter steering wheel from lock to lock. Between kerbs, the stated turning circle is 40 ft. This is commendable for a front-wheel-drive vehicle.

Lubrication Reduced

At present, conventional joints are employed for the steering linkage, but it is hoped that it will be possible to substitute sealed ball-joints, which do not require lubrication, at a later date. If this is done, only the hubs will require regular greasing.

The novel rear suspension needs no lubrication. Cast S.G. iron trailing box-section arms carry upright plates to which the stub axles are bolted. Each arm is pivoted on a robust top-hat-section chassis cross-member through conical rubber bushes spaced 1 ft. 2 in. apart. A Metalastik progressive rubber spring is interposed between the underside of the chassis frame and a circular wearing plate on the upper surface of the arm. The spring is attached by one bolt to the frame. Thus, spring replacement becomes a simple and speedy job.

As the rubber cushion contacts the longitudinal centre of the arm, the ratio of wheel-to-spring movement is 2 to I.

Lever-type shock absorbers are set to give little resistance to upward wheel movements, but much increased damping for downward deflection. Because the spring is entirely separate from the wheel assembly, it has no restraining effect on rebound. It might. be thought that this would place an undue load on the shock absorbers, but, as the unsprung weight is low, this is not so. A check strap is fitted to prevent the wheel dropping when the vehicle is jacked up.

The five-stud wheels carry 7.50-16-in. (8-ply) tyres and 12-in.-diameter brake drums for the Girling hydraulic system. Lining width all round is 2+ in. and this gives a total braking area of 207 sq. in. The hand brake is cableoperated, the cable assembly being pre-lubricated and sealed.

The Vendor chassis frame, like the running components, departs from conventional practice. It is fabricated entirely from Cor-Ten steel. This material was chosen primarily for its good corrosion resistance and fatigue life. It has also a higher tensile strength than normal steel and tends, to be of more uniform quality. These properties were considered to outweigh its greater cost. The entire frame assembly is of welded construction and employs -}-in.-thick material. The members are produced by Dennis, using simple folding and cutting equipment.

Shallow Chassis Frame In the interests of a low floor line, the main longitudinals and cross-members are only 4 in. deep. Four longitudinal channels are employed for the centre section of the frame. These have 2-in.-wide flanges and are joined, just ahead of the rear wheels, by the sturdy cross-member to which the trailing suspension .arms are attached. Behind the front wheels, the outer channels are swept in to join the inner longitudinals, which are dropped slightly at this point and carried on forward to the front of the body.

Where the outer members end, a Z-section cross-member is fitted and 2 ft. behind this point is a channel-section cross-member. The use of four longitudinals provides excellent support for the body floor, making it possible to fit a lighter and thinner structure-2 in. is the recommended thickness—to keep the loading height down. At the rear, two tapered L-section longitudinals extend from the transverse suspension-carrying member and are joined by two shallow cross-members.

The standard front-end structure offered on the Vendor is constructed from plastics. Styling is functional and the full-width bonnet provides excellent access to both sides of the power unit. A one-piece, slightly curved windscreen is flanked by triangular quarter lights. Deep sliding windows a26 are incorporated in the' external sliding doors. Hinged doors are available as an option. The driver's adjustable seat can be reached easily from either cab door, although the straight gear lever, protruding from the steeply angled full-width toeboard, is a slight obstruction on the near side.

The van body, fitted to the oil-engined Vendor which is to appear at the Show is metal-panelled on a hardwood frame. As there is no room for the spare wheel beneath the frame, it is carried behind the off-side rear wheel-arch. The other arch is boxed to form a useful container. An innovation for a vehicle of this size is tubular jacking points provided at each wheel.

New Pax IV. Range

THOSE who are familiar with previous Pax models will I recognize many common components in the Pax IV. The model to be shown at Earls Court will have a B.M.C. 5.1-litre engine and gearbox. The new Pax range includes rigid vehicles for 10-ton and 11+-ton gross weights, and tractors for 12-ton and 154-ton gross train weights. Power units available, other than the B.M.C., are the Perkins Six 305 indirect-injection 5-litre unit and a new Perkins six, cylindered engine, details of which have yet to be released. As before, B.M.C. four-speed or Dennis five-speed gearboxes are available.

Chassis, modifications are confined to details. The Girling braking system has been revised. All models now have 16-in.-diameter . drums at the front with 3-in.-wide linings. Rear drums are 15.1 in. in diameter, with 4+-in.wide linings on 10-ton-gross vehicles and 5-in.-wide linings on the heavier units. . A Clayton Dewandre HSR1/950 Hydrovac reduces braking effort.

Steering on all Pax IV models is by Burman recirculating ball gear, whilst Dennis have reverted to mechanical clutch operation in place of a hydraulic system.

The cab developed for the Pax IV retains the entrance step ahead of the wheels. The steel underframe is now attached to the chassis through four rubber mountings, instead of at three points. This arrangement "simplifies engine changes, as the front member can be removed easily to allow the power unit to be drawn out. The cab has a large single-piece windscreen without excessive wrap-around and a particularly, attractive, though simple, fascia layout.

Paired headlamps are included in the specification. -

Air-suspension Loline

A IR suspension of the type fitted to sOme earlier Loline I–I chassis is standard on the rear axle of the new Loline Mark III with leaf-springing as an option. Other changes include the use of an all-indirect five-speed constant-mesh gearbox and a redesigned cab foundation which permits easier servicing access to the engine and radiator.

The rear axle of the latest Loline is carried on trailing beams which are, in fact, very stiff leaf springs, made up to five laminations. Behind the wheels, the springs are bolted to a transverse beam, the outer ends of which carry the Andre rolling-lobe-type air springs, each of which is augmented by a spherical surge tank.

The Loline Mark III is offered with Gardner 6LW or 6LX engines coupled to either a four-speed semi-automatic transmission or the new five-speed gearbox. The latter unit has forward ratios of 4.07, 2.375, 1.454, 0.976 and 0.653 to I. Bottom gear, lower than ratios used before, gives a maximum gradient ability of 1 in 6.3 fully laden.

Forwardor rear-entrance bodies can be fitted to the chassis, which is offered in wheelbases of 16 ft. 11 in. or 19 ft. 2 in. The longer wheelbase model will appear at Earls Court with a 6LW engine, five-speed gearbox and 30-ft.long forward-entrance body.