Girling Disc Brake Now on General Sale

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

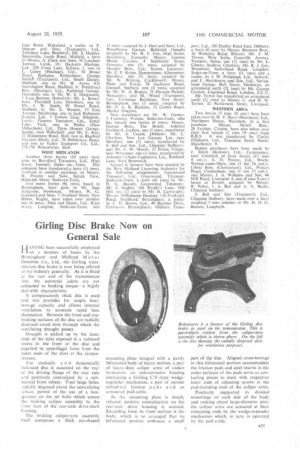

HAVINHAVING been successfully employed on a number of buses by the Birmingham and Midland Motor Omnibus Co., Ltd., the Girling transmission disc brake is now being offered to the industry generally. As it is fitted at the rear end of the transmission line, the univerial joints are not subjected to braking torque—a highly desirable characteristic.

A comparatively thick disc is used and this provides for ample heatstorage capacity and allows internal ventilation to promote rapid heat dissipation. Between the front and rear braking surfaces of the disc are radially disposed cored slots through which the ventilating draught passes.

Draught is picked up by the inner ends of the slots exposed in a radiused recess in the front of the disc and expelled by centrifugal force from the outer ends of the slots at the circumference..

The statically a n d dynamically balanced disc is mounted on the rear of the driving flange of the rear axle and positively centralized by a substantial front rebate. Four large holes, radially disposed about the centralizing rebate, permit of the use of a boxspanner on the set bolls which secure the braking caliper assembly to the front face of the rear-axle drive-shaft housing.

The braking caliper-arm assembly itself comprises a thick arc-shaped mounting plate integral with a partly bifurcated body of heavy section, a pair of heavy-duty caliper arms of rocker formation, an anti-corrosive housing containing a Girling C.V.-type wedgeexpander mechanism, a pair of outside cylindrical friction pads and an armoured pull-cable.

As the mounting plate is deeply rebated, positive centralization on the rear-axle drive housing is assisted. Extending from its front surface is the • body, which is so arranged that its bifurcated portion embraces a small

part of the disc. Aligned cross-borings in this bifurcated portion accommodate the friction pads and steel inserts in the outer surfaces of the pads serve as contacting pieces to mate with respective inner ends of adjusting screws in the pad-clamping ends of the caliper arms.

Positively supported in divided mountings on each side of the body and rocking about large-diameter pins, the caliper arms are actuated at their remaining ends by the wedge-expander mechanism which, in turn, is operated by the pull-cable.