DESIGN FOR AUTOMATION

Page 50

Page 51

Page 52

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

How the Introduction of the Automatic Factory May Affect the Design ofCommercial Vehicles: Turbo-blowers a Factor of the Future By P. A. C. Brockington,

A.M.I.Mech.E. has yet to be exploited to its full potential. It will almost certainly revolutionize production methods, and the life of the nation, in the foreseeable future, probably to a greater extent than the successful peaceful application of nuclear energy, and the vehicle industry will be the first to be affected. The revolution has, in fact, already started.

Thoughts of an industrial revolution tend towards grandiose conceptions of startling developments in the form of motive power that will be used for vehicles. It has been suggested that the gas turbine is already outdated and whimsical minds look to the nuclear power pack for inspiration. In reality, ease of production and the creation of markets in hitherto undeveloped areas may give existing types of power unit and other components a new lease of life, given that standardization can he adjusted to the flexibility of users' requirements.

Before enlarging upon this aspect of future trends, however, it is appropriate to examine some of the factors that now influence production costs apart from quantity. One of the most important is machining accuracy, which is often far. more important than the degree of complication. Another is the number of inspections required by skilled operators.

Although the piston engine is a highly developed machine produced to accurate limits, the finish of its working parts cannot be compared with that of a turbine, which must be built to rotate at many times the r.p.m. of a reciprocating unit and must be perfectly balanced. The amount of " workmanship " required in the production of a turbine, as distinct from the number of processes that can be completed by a machine, is likely to remain a differential of importance. Despite the comparative simplicity of the turbine in its principle of operation, it may be far less amenable to automation (perish the term).

The quality of the materials is also a factor, the effect of which varies with its proportional relationship to overall production cost. In a hand-built machine produced in limited quantities for a long service life, the use of high-quality materials represents a relatively small percentage of the first cost, and an even smaller

impossible in the event. of any mechanical trouble; replacement would be the only course and possibly less costlythan an overhaul.

The effect of automation on labour charges is difficult to forecast. • If factory requirements were reduced to a comparatively small fraction of existing man-hours, this might be accommodated by a reduction in the length. of the working day rather than the labour force. Whatever the outcome, it is unlikely that repairers and operators would be provided with cheap labour. The growth of automatic production would be concomitant with a stimulated national economy or state of war; both would maintain labour rates.

Reverting to engine developments, a decrease in the cost of fuel is far less probable than a drop in production and maintenance costs. Fuel would therefore represent a higher proportion of the operator's payments and fuel economy a more valuable asset. Although the development of an efficient heat exchanger for gas turbines is a practical certainty, it is unlikely that the fuel consumption of the turbine will ever be improved over that of the petrol engine. The small size and weight of the turbine without a heat exchanger gives a misleading picture of its dimensional advantages.

For a given temperature difference, heat transfer is a function of surface area, and a unit providing optimum efficiency is of necessity bulky. Moreover, the high quality of the materials employed in the construction of a heat exchanger providing optimum efficiency increases its cost, and high thermal stresses create maintenance problems.

Turbine efficiency can also be raised by using multi stages for the power turbine and complicated blade-cooling methods. It is a machine that has the advantage of extreme simplicity in a " utility " form, but will become more and more complicated as measures are taken to improve efficiency. As a candidate for automation its election is very doubtful.

No review of production trends can be regarded as realistic without reference to road developments; it will be many years, even generations, before the creation of a highway system could match existing needs. That they can possibly catch up with the expansion of vehicle output in the foreseeable future is a remote possibility. Increasing road congestion and traffic delays are inevitable and as fuel consumption is, in practice, a product of hold-up-time as well as journey distance, its importance will increase. If a fleet of trunking vehicles could operate at an unrestricted speed on a dual-carriage highway without having to contend with traffic congestion the ideal power unit might be very different from the most suitable unit for the conditions prevailing and envisaged for the future. (Left) In the RicardoWellworthy blower, the pistons are reciproceded through the action of a wobble plate which is driven from the engine. It promises to improve the lowspeed torque of the oil

engine.

A compression-ignition engine possesses the outstanding virtue for " part-throttle " operation that the incoming air is not, in fact, throttled and the compression ratio remains substantially constant throughout the speed range. For this reason many operators, on the ground of economy, prefer to employ an over-powered oil-erigined vehicle in place of one fitted with a smaller unit. If it were not for considerations of cost, weight and size, more powerful units would be generally acceptable for small vehicles, particularly if they were derated to Prevent speeding.

To use a petrol engine with an unnecessarily high maximum output would, on the other hand, inevitably be wasteful, because it would be " throttled " for most of its working life. figures are not available showing the part-load fuel consumption of a gas turbine compared with full-load consumption, but reasoning, based on first principles, indicates that the oil engine would be far more economical when propelling a vehicle in heavy traffic and when running light than a comparison of specific consumptions on full-load would indicate.

Although automation should favour the perpetuation of the oil engine despite its weight and size, one particular objection to its continued use must be stated. This is its dependence upon a multi-speed gearbox to provide the necessary torque range. The driver would obviously prefer a turbine of the more complicated freeaxle type, on account of its high low-speed torque and the freedom from gear changing it provides. The development of an automatic type of transmission which can be produced in quality at low cost by the latest machine tools could, therefore, play an important part in determining the future of the oil engine.

Demands of Operators It may be pertinent to point out that the use of torque converters was discontinuedin this country 'because of a relatively small reduction in overall efficiency. The difference between turbine and oil.engine , efficiencies is incomparably greater than the small margin leading to the eclipse of the converter; a point which serves forcibly to illustrate the vast improvement in turbine efficiency that is necessary before •the unit would be acceptable to commercialvehicle operators.

It is also appropriate to emphasize that some design features which tend to give a cleaner exhaust and reduce Diesel knock have also been largely discontinued because of what can be rightly described in this context as insignificant losses in . efficiency. They show the effect that a fractional increase in m.p.g. can have on design.

Reducing the cost . of power units produced. in quantity, even without the development of full automation, is partly a function of standardization, which is practised to a greater extent by the manufacturers of commercial-vehicle oil engines than by the makers of petrol engines for cars.

Supercharging Standardized

A range of units with outputs depending upon the number of cylinders of the same bore and stroke dimensions is commonplace, and Rolls-Royce, Ltd., go farther in that they augment the range offered without increasing the number of basic units by employing mechanically driven superchargers; these form standard equipment on some of the models. So that production could be simplified and space requirements satisfied, the engines are designed and built for pressure charging.

It is necessary at this stage to reiterate the possible advantages of pressure charging an oil engine compared with supercharging a petrol-driven unit. In both cases the load on the bearings is increased, but because the oil engine operates on the constant-pressure cycle, as distinct from the constant-volume cycle of the petrol engine, an increase in intake pressure does not raise the peak cylinder pressure proportionately. I3y pressure charging the power output can be raised a substantial n18 amount for a small increase in maximum pressure, the additional load being spread over a large crank angle.

Moreover, detonation is not a limiting factor and it is unnecessary to reduce the compression ratio and so lower the thermal efficiency. The Rolls-Royce range comprises four-, sixand eight-cylindered units with outputs of 60 b.h.p. to 300 b.h.p. An indication of the gain in power provided by the superchargers is shown by a comparison between the maximum rating of the .uriblown eight-cylindered unit and of -the blown version. The power is raised from 246 b.h.p. to 300 b.h.p.

Simplified Production

Although superchargers are of comparatively high cost, their value in simplifying production would be increased with the advent of automation without detriment to the user. The vehicle manufactuter would,in fact, benefit by the availability of high-powered engines of relatively small size and weight. If the blower were of the exhaust-driven type he would also gain by a reduction in fuel consumption.

The development of a mechanically driven pressure charger having the characteristics necessary for an appreciable improvement in low-speed torque, would have the same result on accountof the less frequent :need of the lower gears; alternatively, the vehicle could be fitted with a final drive having a higher ratio.

The forecast that after an interval of a few years the • majority, of oilengines produced for commercial vehicles will be fitted with superchargers as original equipment, is probably justified, whether it is based on existing production processes or fully automatic methods. What type of blower will it be?

High Low-speed Torque

In The Commercial Motor for April 15, a description was given of the Thornycroft KRN 6 11.3-litre turboblown oil engine fitted to a Big Ben test vehicle, having a gross laden weight of tons. The blower is an Eberspacher unit of German origin, which increased the power output of the basic engine from 155 b.h.p. to 200 b.h.p. at the same r.p.m. of 1,900. The torque was increased from 508 lb. ft. to 625 lb. ft. at 1,000. r.p.m. According to the makers of the turbo-charger, an average saving in specific fuel consumption of about 9 per cent. is normally effected.

The Eberspacher blower is small and of light weight: If a. 200-b.h.p. unsupercharged engine were produced with the same power-to-weight ratio as the smaller unit it would weigh about 7 cwt. more than the blown basic unit.

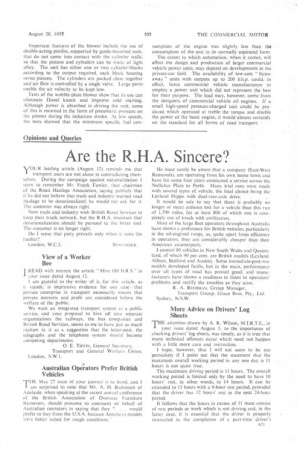

In the forthcoming battle of the blowers, a contender for honours will undoubtedly be the RicardoWellworthy wobble-plate type, which has the disadvantage of being mechanically driven and therefore of absorbing useful power, but promises to provide a very high low-speed torque.

The margin for safety for torque increase in a typical oil engine is large at low speed_s, because the thermal stresses are relatively small. Theoretically, it should be possible to operate at double the normal torque up to at least 50 per cent. of the rated speed. If the supercharger output-characteristic were such that this could be achieved without undue mechanical losses, the gain in performance would be of very great value, and-few, if any, modifications to the engine would be required unless the blower was used materially to -increase the high-speed output. If the engine were designed for supercharging the overall gain might be much greater. The Ricardo-Wellworthy supercharger was specially developed to give a good low-speed characteristic. Important features of the blower include the use of double-acting -pistdns, supported by guide-mounted rods, that do not come into contact with the cylinder walls., so that the pistons and cylinders can be made of light alloy. The unit has either one or two cylinder-blocks according to the output required, each block housing seven pistons. The cylinders are packed close together andair flow is controlled by a single valve. Large ports enable the air velocity to be kept low.

Tests of the wobble-Plate blower show that its use can eliminate Diesel knock and improve cold starting. Although power is absorbed in driving the unit, some of this is returned in the form of pneumatic pressure on the pistons during the induction stroke. Al low speeds, the tests showed that the minimum specific fuel con

sumption of the engine was slightly less than the consumption of the unit in its normally aspirated form.

The extent to which automation, when it comes, will affect the design and production of larger commercial vehicle power units, may depend on developments hi the private-car field. The availability of low-cost " throw away" units with outputs up to 200 b.h.p. could, in effect, force commercial vehicle manufacturers to employ a power unit which did not representthe best for their purpose. The lead may, however, come from the designers of commercial vehicle oil engines. , If a small high-speed pressure-charged unit could be produced which operated at treble the torque and double the power of the basic engine; it would almost certainly set the standard for all forms of road transport. '