LONDON'S NEW OMNIBUS.

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

A Technical Description of the K-type Chassis Designed for Greater Seating Accommodation within Scotland Yard's Limits.

THE LATEST PRODUCT from the A.E.C. factory, the K-type omnibus, built for the London General Omnibus Co., Ltd., is creating considerable interest both amongst the public and in the cbtx.rnercial-vehicle world, and fuller details of its construction,are anxiously awaited in both directions. Fortunately, we have been able to obtain these, together with pliutographs of the chassis. and ,ar number of sketches showing interesting points.

The task which was before the designers of the Ktype was to build an omnibus capable of holding a greater number of passengers, not only without increasing the weight of the vehicle, but actually reducing it somewhat, whilst at the same time it was imposSible to lengthen the vehicle by more than a few inchei or ;to widen it to any extent whatsoever. Moreover, with a heavier load on the roof, the centre of gravity was to be kept low.

Many people seem to have the idea that the new bus is a vehicle designed for luxury travel. This view of the matter is quite a mistaken one ; certainly, owing to the new points embodied, it is more romfortable than the B-type, but it is essentially a utility machine built for efficiency, safety and for the rapid loading and unloading of its human "freight. Its design in these respects reflects great credit on the constructors.

The new bus is so built that the driver sits on one side of the engine, and the body is extended so that it occupies the space previously taken up by the driver. The body is also much wider, but, as previously stated, this has not widened the machine as a whole. We need not enter into further details of • the construction of the body as many photographs of the bus have already been published.

In order to keep our description of the chassis brief we intend chiefly to deal with departures from the design of the B-type.

The frame is of the, flitch-plate type, as before, but is extended on the near side to carry the passenger platform. It is inswept slightly towards the front so that the steering lock is increased.

The engine is four-cylindered of 100 mm. bore by 140 mm. stroke, with the cylinders cast in pairs, all the valves being on one side. The engine is inclined in order to prevent excessive angularity of the rear cardan. shaft. It is provided with a three-point silent-chain drive to the camshaft and the magneto, the spindle of the latter being so arranged that it can slide for the purpose of chain adjustment.

The water circulation is by centrifugal pump, this being driven by a separate enclosed chain from the magneto shaft. The crankcase is extended below the centre line of the crankshaft, which gives a somewhat stifferconstruction than when it is jointed at the crankshaft Centre. The side nearer to the driver's seat is practically vertical to afford the necessary clearance. Lubrication is by the pump and trough system, a pump of the gear type being driven by skew gears from the crankshaft. It is wholly mounted on the top half of the crankcase. The timing chain is fed with oil from a separate pipe which throws a -jet from the inside of the camshaft wheel.

Aluminium pistons are provided, and a new feature is the clamping of the gudgeon pins in the connecting rods, the former running direct in the pistons. When wear above the permissible tolerance takes place in the piston bosses, these will be bored out and bushed to receive the gudgeon pins. The new chassis has had a test of over 5,000 miles, and it has been found that there is no appreciable wear between the gudgeon pins and the pistons.

The radiator is of the standard type with aluminium top and bottom tanks and side brackets, but, in order to ensure adequaie.cooling and efficiency, it is made with five rows of tubes, only the four back rows being gilled, and the front one being of plain copper tubes, this latter point being chiefly for the sake of neat appearance.

The drive is taken through a multiple plate clutch provided with steel discs and floating Perodo rings which run dry. It has a central spring, and small additional springs are provided between the plates in order to obtain positive disengagement. The clutch withdrawal gear, is direct acting, and is the subject of one of the several patents incorporated in the design. The clutch itself is very compact and of small diameter.

A gearbox of the silent-chain type, very similar to that used on the' B-type, but of smaller dimensions, gives three forward speeds and a reverse ; the shaft between it and the clutch has two flexible joints of the multiple Steel-disc type.

From the gearbox a caedan .shaft, provided with two universal joints, conveys the drive to an underneath worm carried direct in "the cast-steel axle casing. The universal joint pins run on roller hearings, the end thrust of the jaws being taken up by hardened steel discs carried in the joint cages. Boththe front and back cardan shafts are made of nickel chrome steel and provided with splined ends. The front ,s.haft-,-that between the, clutch and the gearbax—slides at its rear end, and the rear shaft at its front end.

The rear axle has been lightened considerably chiefly owing to the fact that the system of slinging the worm gear and differential from the cover has been done away with ; in addition, the back axle tubes are pressed direct into the central casing without the use of additional extending castings as in the B-type axle.

In order to reduce the height of the centre of gravity of the whole bus by 6 ins., much attention has been paid to the springing, and the rear springs are underslung. The spring pads which carry the brake anchors and which transmit the torque direct to the springs ate of the floating type.; the driving torque is taken by a spring-plate toraue stay, bolted to the axle casing and held at the front end in a spherical bearing of which the ball cups are insulated on rubber pads.

A point of particular interest in the design lies in the rear road wheels, which are detachable from their hubs; the latter have tapered exteriors which fit into the wheels, these being driven by dogs on the hub and pulled up into position by left and.right-hand screwed slots. The hubs run on Timken, bearings, and the removal of the wheels does not affect these bearings in any Way.

Both the hand and foot brakes operate on the rear wheels, one brake .drum being inside. and concentric with the other on each wheel, the band brake operating on the smaller drums. Nothing much' need be said of the wheels apart from the point already mentioned. They are made from steel castings and are of equal diameter front and rear.

The front axle is an "H" section stamping in per cent, nickel steel, the swivels are jawed and the swivel pins are fixed in these jaws on ,tapers. The swivel pins arc inclined outwards to bring the tracking points as close as passible to the centres of the front wheel tyres where they touch the ground. This, of course, gives easier steering, and, in addition, a slight self-tracking effect.

The steering gear is of the worm and nut type, the main coupling operating across the chassis and attached to a boss in the-centre of the cross arm at the near side. Both coupling rods are situated behind the axle.

To assist in reducing the number of units the clutch and brake pedals are carried on the steering box.

The road springs are wider and longer than in the B-type, and the compound volute springs over the back axle are arranged so that the weight of the bus when empty comes almost entirely on the main springs, whilst the volute springs carry a large proportion of the passenger weight when the bus is loaded.

A lighting dynamo is so arranged that it can be driven from the front of the engine by means of a belt.

The finaldrive gear ratio is 8.25 to 1, and the differential is of the standard bevel type.

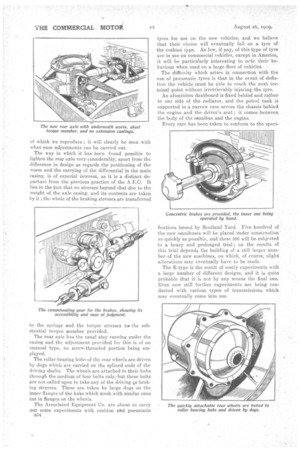

Careful attention has been paid to details and to accessibility. A good example of this .is shown by the brake adjustment and compensating gear, a sketch of which we reproduce ; it will clearly be seen with what ease adjustments can be carried out.

The way in which it has been found possible to lighten the rear axle very considerably, apart from the difference in design as regards the positioning of the worm and the carrying of the differential in the main casing, is of especial interest, as it is a distinct departure from the previous practice of the A.E.C. It lies-in the fact that no stresses beyond that due to the weight of the axle casing, and its contents are taken by it ; the whole of the braking stresses are transferred to the springs and the torque stresses te. the substantial torque member provided.

The rear axle has the usual stay running under the easing and the adjustment provided for this is of an unusual type, no screw-threaded portion being employed.

The roller-bearing hubs of the rear wheels are driven by dogs which al e carried on the spline(' ends of the driving shafts. The wheels are attached to their hubs through the medium of four bolts only, 'but these bolts are not called upon to take any of the driving gr braking stresses. These are taken by large dogs on 'the inner flanges of the hubs which mesh with similar ones Cut in flanges on the wheels. .

The Associated Equipment Co. are about to carry out some experiments with cushion arid pneumatic 1334 tyres for -use on the new vehicles, and we believe that their choice will eventually fall on.. a tyre of the cushion type. As few, if any, of this type of 'tyre are in use on commercial vehicles, except in.Ainerica, it will be particularly interestingto. note their" behaviour wben used on a large fleet of vehieles. .

The difficulty which arises_ in connection with: the use of pneumatic tyres is that in the event. of deflation the vehicle must be able to reach .the nest terminal point :without irretrievably injuring _thn.tyie.

An aluminium dashboard is-fixed behind.and rather to one side of the radiator, and, the_petrol tank' is supported in a narrow case across the thessis-1.ehind the engine and the -driver's seat; it comes-between the body of the omnibus and the engine. .

Every care. has been takento conform to the speci fications issued by Scotland Yard. Five hundred of the new omnibuses will be placed under construction as quickly a s possible, and these 500 will be subjected to a heavy and prolonged trial ; on the results of this trial .depends the building of a still larger number of the new machines, on which, of course, slight alterations may eventually have to be made.

The K-type is the result of costly experiments with a large number of different designs, and it is quite probable that it is not by any means the final one. Even now still further experiments_ are being conducted with various types of transmissions which may eventually come into use.