Driving on all wheels

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Most good ideas seem obvious, once you've been shown how. The Multidrive concept, for example, gives you an all-terrain load carrier with the capacity of an artic. No wonder it has a growing band of admirers.

It was at Harrogate four years ago that Multidrive (one of the David J B Brown group of companies which now includes AWD) launched its allwheel-drive-and-steering system for articulated trailers.

Few detail changes have been made to the earlier design for off-road dumpers. The live trailer bogie is positively driven through a set of three propellor shafts from the tractive unit. The centre shaft incorporates extra-long splines and a flexible joint to cope with the movement between tractive unit and trailer.

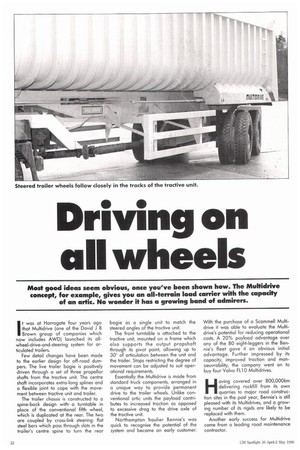

The trailer chassis is constructed to a spine-back design with a turntable in place of the conventional fifth wheel, which is duplicated at the rear. The two are coupled by cross-link steering: flat steel bars which pass through slots in the trailer's centre spine to turn the rear bogie as a single unit to match the steered angles of the tractive unit.

The front turntable is attached to the tractive unit, mounted on a frame which also supports the output propshaft through its pivot point, allowing up to 30of articulation between the unit and the trailer. Stops restricting the degree of movement can be adjusted to suit operational requirements.

Essentially the Multidrive is made from standard truck components, arranged in a unique way to provide permanent drive to the trailer wheels. Unlike conventional artic units the payload contributes to increased traction as opposed to excessive drag to the drive axle of the tractive unit.

Northampton haulier Bennie's was quick to recognise the potential of the system and became an early customer. With the purchase of a Scammell Multidrive it was able to evaluate the Multidrive's potential for reducing operational costs. A 20% payload advantage over any of the 80 eight-leggers in the Bennie's fleet gave it an obvious initial advantage. Further impressed by its capacity, improved traction and manoeuvrability, the company went on to buy four Volvo FL10 Multidrives.

Having covered over 800,000km delivering rockfill from its own quarries to major road construction sites in the past year, Bennie's is still pleased with its Multidrives, and a growing number of its rigids are likely to be replaced with them.

Another early success for Multidrive came from a leading road maintenance contractor. Colas Roads developed a tanker/ sprayer based on the Scammell Multidrive some two years ago. Its exceptional manoeuvrability allowed it to operate down narrow and winding country lanes and through housing estates where sixwheelers had struggled for access. The rear-steered axles allow the trailer to follow closely in the tracks of the tractive unit, so cut-in is minimal.

The Multidrive Tanker sprayer has increased Colas' carrying capacity by 70%; enough to allow the road resurfacing teams to work a full day's shift without refilling.

Contract process manager David Fairchild sums up the Multidrive succinctly: "This system has doubled our productivity." Colas has increased its fleet to three, with another on order.

Greater productivity shows up in various ways. Kettle and Co of Stoke on Trent operates four Multidrives on a range of operations, including hauling contaminated waste to its landfill sites.

Being able to enter areas of sites inaccessable to conventional rigids and other artics, they fit in well with the overall operation by allowing other site machinery, such as tracked dozers to operate more efficiently by needing to spend less time preparing ground for conventional tippers.

Avron Transport of Gatwick found similar benefits hauling top soil from Ashington trout farm. The narrow and deeply rutted access roads, with awkward adverse cambers, are virtually impassable for eight-wheelers. Shunting to and fro with a Multidrive is unnecessary, so its exceptional traction and manoeuvrability allow quicker turn-round times.

Egerton Transplant of Dukinfield is one of the most recent converts to Multidrive. Operating a pair of Seddon Atkinson Multidrives, mainly out of quarries in Derbyshire, it has found that the added traction can readily handle the slippery site access conditions caused by rain.

Depending upon the specification, a complete 38-tonne GCW vehicle costs around E70,000 but, says Multidrive, the trailer pays back with much lower operating costs per tonne. Although residual values are difficult to establish, it is understood that Multidrive operators have found it easy to sell their vehicles.

At next week's TipCon show Multidrive will be showing two vehicles. One has covered over 160,000km and the other is the new flexible eight-wheeler from AWD. At 32.5 tonnes it offers all of the benefits of a Multidrive, with a 4x2 tractive unit giving a maximum payload potential of 21 tonnes.