Bodybuilding keeps Telehoist in shape

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

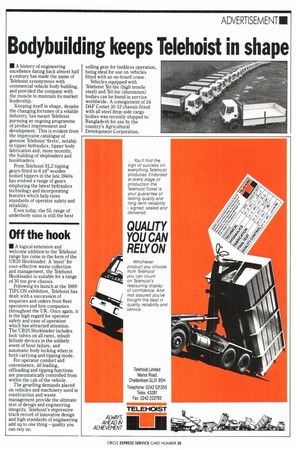

II A history of engineering excellence dating back almost half a century has made the name of Telehoist synonymous with commercial vehicle body building, and provided the company with the muscle to maintain its market leadership.

Keeping itself in shape, despite the changing fortunes of a volatile industry, has meant Telehoist pursuing an ongoing programme of product improvement and development. This is evident from the impressive catalogue of genuine Telehoist 'firsts', notably in tipper hydraulics, tipper body fabrication and, more recently, the building of skiploaders and hookloaders.

From Telehoist SL2 tipping gears fitted to 6 yd3 wooden bodied tippers in the late 1940s has evolved a range of gears employing the latest hydraulics technology and incorporating features which help raise standards of operator safety and reliability.

Even today, the SL range of underbody rams is still the best selling gear for tankless operation, being ideal for use on vehicles fitted with an on-board crane.

Vehicles equipped with Telehoist Tel-lite (high tensile steel) and Tel-by (aluminium) bodies can be found in service worldwide. A consignment of 24 DAF Comet 10-12 chassis fitted with all steel drop-side cargo bodies was recently shipped to Bangladesh for use by the country's Agricultural Development Corporation.