Van Bodywork that Saves Money

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

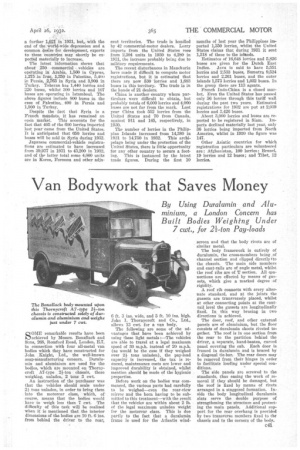

SOME remarkable results have been achieved by Messrs. Bonallact and Sons, 268, Rumford Road, London, E.7, in connection with four all-metal van bodies which they have constructed for John Knight, Ltd., the well-known soap-manufacturing concern. Duralumin and aluminium are used for the bodies, which are mounted on Thornycroft AT-type 2i-ton chassis, these weighing, unladen, 2 tons 3 cwt.

An instruction of the purchaser was that the vehicles should scale under 2i tons unladen, in order to bring them into the motorcar class, which, of course, means that the bodies would have to weigh less than 7 cwt. The difficulty of this task will be realised when it is mentioned that the interior dimensions of the bodies are 10 ft. 6 ins. from behind the driver to the rear,

6 ft. 3 ins, wide, and 5 ft. 10 ins. high, John I. Thornycroft and Co., Ltd., allows 13 cwt. for a van body.

The fallowing are some of the advantages that have been achieved by using these light metals :—The vehicles are able to travel at a legal maximum speed of 30 m.p.h. instead of 20 nt.p.h (as would be the ease if they weighed over 2i. tons unladen), the pay-load capacity is increased, the tax is reduced, maintenance costs are lower and improved durability is obtained, whilst mention should be made of the hygienic properties.

Before work on the bodies was commenced, the various parts had carefully to be weighed—even the rear-view mirror and the horn having to be submitted to this treatment—with the result that the vehicles are within about 2 lb. of the legal maximum unladen weight for the motorcar class. This is due partly to the fact that a duralumin. frame is used for the Atlantis wind

screen and that the body rivets are of similar metal.

The body framework is entirely of duralumin, the cross-members being of channel section and clipped directly to the chassis. The main side members and cant-rails are of angle metal, whilst the roof ribs are of T section. All cannectians are effected by means of gussets, which give a marked degree of rigidity.

A roof rib connects with every alternate standard, and at the joints the gussets are transversely placed, whilst at other connecting points at the cantrait level the gussets are longitudinally fixed. In this way bracing in two directions is achieved.

The door, roof, and other external panels are of aluminium, but the floor consists of duralumin sheets riveted to gather. The roof is in one section from the rear to the partition behind the driver, a separate, hand-beaten, curved panel covering the cab. Each door is framed in duralumin and is braced by a diagonal tie-bar. The rear doors may be removed from their hinges in order to facilitate loading under special conditions.

The side panels are screwed to the standards, thus easing the work of removal if they should be damaged, but the roof is fixed by means of rivets arranged in a staggered formation. Inside the body longitudinal duralumin slats serve the double purpose of strengthening the structure and protecting the main panels. Additional support for the rear overhang is provided by two transverse members fixed to the chassis and to the corners of the body.