Tilt Cabs for New Austin and Morris Ranges

Page 131

Page 132

Page 133

Page 134

If you've noticed an error in this article please click here to report it so we can fix it.

A.RANGE of four new goods vehicles (5-, 7and 8-ton rigids and an 18-ton gross tractive unit) has been introduced by the British Motor Corporation at the 2ommercial Motor Show, which opened today. Designated 711(.100, 140, 160 and 360 respectively, they will replace he existing FHK.100 5-tonner, the FHK.I40 7-tonner, the =•HK.160 8-tonner and the FFK.360 18-ton gross tractive init.

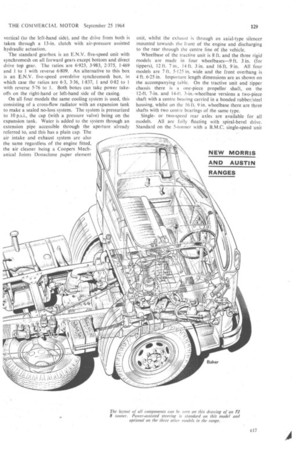

Although the new models are fitted with existing B.M.C. tiesel engines, in every other respect the chassis are corn)letely new designs and have a number of interesting and ommendable features including an advanced braking ystem, the use of an E.N.V. five-speed synchromesh box Ind, probably of most importance, a completely new iesign of forward-entry full-tilt cab.

The cab is identical on all the Elmodels and is of anteel with welded construction. The engine is below the eat supPort pressing, so allowing for a double passenger eat in addition to the driver's seat with free access across the cab. As the complete cab tilts, it is necessary to remove the steering wheel and steering shaft from the box; but this is a simple operation requiring only the looSening of the clamp bolt. The tilting is controlled by a torsion bar at the front pivot points, this being fixed in a bracket at the left-hand sidemember. supported in a similar bracket on the right-hand member and having splined at its free end a bracket through which the torque is transmitted to the cab structure. The bracket is relatively short and is fixed by three bolts to the underside of a sturdy box-section member which is one of the two main longitudinals of the cab substructure. The second longitudinal member is in a similar position over the left-hand frame sidemember, and provides the mounting for the left-hand cab hinge bracket. This has a spring-loaded locking plunger, which can be used to hold the cab in the raised position, and also incorporates a safety stop to restrict the tilt. In the " down "position, cones on the centre portions of cylindrical rubber/steel support bushes fixed to the rear of the cab locate in brackets on the chassis sidemernbers. The cab is held down by bolts through the supports into the brackets.

if the work to be done on the engine does not warrant the tilting of the cab, comparatively good access to the engine can be obtained by raising a cover in the seat support pressing, this being held in place by six easy detachable fixings, The cover is actually underneath the double passenger seat and this is moved out of the way by dropping the back onto the seat squab. the whole unit can then be hinged upwards towards the left-hand side door. A smaller panel between the driver and passenger seat gives access to the engine oil dip stick, and a cover in a panel below the driver's seat has to be removed to get access to the cooling system header tank filler and the engine oil filler. '

The standard of finish and fittings inside the cab is very high, and a good deal of attention has been paid to make the driver comfortable and his work as easy as possible. The seats are softly padded and trimmed in P.V.C.-coated material, with centre areas of both the cushions and backrests being made of breathable Vynair plastics material. Besides being adjustable fore and aft and vertically, the driver's seat has a back-rest, the angle of which can be adjusted. The facia panel carries a central instrument nacelle with pockets either side, and a foam-loaded trim• covered with black P.V.C. is used on the top surface of the panel, around the instrument nacelle, and along the lower edge of the panel. Both doors have their internal panels covered with P.V.C. and carry large pockets for documents and the like. The doors are hinged at the forward edges and check straps permit them to open to 900. Full-drop winding windows and swivelling quarter lights are fitted in both doors.

Three windows are fitted to the back, the two outside ones going partly round the corner; the central one is fitted with a balanced drop glass.

The windscreen is of good size—larger than on the chassis replaced—and is of toughened glass with a safety zoned area in front of the driver. Dual wipers are mounted below the bottom edge of the screen—these have 14-in. blades—and windscreen washers are fitted as standard. A 5-kV. heater and demister unit is also fitted as standard, although this is optional equipment for export.

Instrumentation in the new models is fairly comprehensive, the instrument cluster, which is of the printed circuit type, comprising a speedometer, fuel and water temperature gauges, an ammeter, oil-pressure gauge, dual air-pressure gauges and an engine oil-level indicator as well as the usual warning lights for dynamo charging, main beam and flashing indicators. Lighting and flashing-indicator switches are mounted on the steering column; but on the header rail above the windscreen and immediately in front of the driver there is n switch panel fitted with rocker type switches for windscreen wipers, panel light and heater switches and one which brings into action the engine oillevel indicator on the instrument cluster. Provision is made for extra switches to be fitted as required and each switch is marked with an identification sign. The floor area is covered with a moulded rubber mat and other fittings include a sun visor, ashtray and coat hooks, and fixings for safety belts are provided.

Access to the cab is made easier by forward-entry steps ahead of the fronl wheels and integral with the cab structure. On the 8-ton model fitted with 9.00-20 tyres the height of this first step is in the region of 2 ft. from the road—this varies between models according to tyre sizes and could be a little less when the springs have settled. From the steps to the floot of the cab is a further 1 ft. 3 in. Grab handles are fitted to the front pillars to further improve aceess.

As stated earlier, the engines used in the new range are existing B.M.C. units, these being the 5.1and 5.7-litre diesels. The 5.1-litre unit is fitted in the 5-tonner only and this produces a maximum net output of 90 b.h.p. al 2,400 r.p.m. and a maximum net torque of 224 lb. ft. a1 1,500 r.p.m. The 5.7-litre engine is fitted in the other three models, this producing 105 b.h.p. at 2,400 r.p.m. and 255 lb. ft. at 1,750 r.p.m. In the case of both engines the unit is mounted in the chassis at an angle of 61° to the vertical (to the left-hand side), and the drive from both is taken through a 13-in, clutch with air-pressure assisted hydraulic actuation.

The standard gearbox is an E.N.V. five-speed unit with synchromesh on all forward gears except bottom and direct drive top gear. The ratios are 6-923, 3.983, 2-375, 1.469 and 1 to 1 with reverse 6.809. An alternative to this box is an E.N.V. five-speed overdrive synchromesh box, in which case the ratios are 6.3, 3.36, 1.837, 1 and 0.82 to 1 with reverse 5.76 to 1. Both boxes can take power takeoffs on the right-hand or left-hand side of the casing.

On all four models the same cooling system is used, this consisting of a cross-flow radiator with an expansion tank to make a sealed no-loss system. The system is pressurized to 10 p.s.i., the cap (with a pressure valve) being on the expansion tank. Water is added to the system through an extension pipe accessible through the aperture already referred to, and this has a plain cap. The air intake and exhaust system are also the same regardless of the engine fitted, the air cleaner being a Coopers Mechanical Joints Donaclone paper element unit, whilst the exhaust is through an axial-type silencer mounted towards the front of the engine and discharging to the rear through the centre line of the vehicle.

Wheelbase of the tractive unit is 8 ft. and the three rigid models are made in [our wheelbases-9 ft. 3in. (for tippers), 12 ft. 7 in., 14 ft. 3m, and 16 ft. 9 in. All four models are 7 ft. 5.125 in. wide and the front overhang is 4 ft. 6.25 in. Important length dimensions are as shown on the accompanying table. On the tractive unit and tipper chassis there is a one-piece propeller shaft, on the 12-ft. 7-in. and 14-ft. 3-in.-wheelbase versions a two-piece shaft with a centre bearing carried in a bonded rubber/steel housing, whilst on the 16 ft. 9 in. wheelbase there are three shafts with two centre bearings of the same type.

Singleor two-speed rear axles are available for all models. All are fully floating with spiral-bevel drive. Standard on the 5-tonner with a B.M.C. single-speed unit is a ratio of 5.86 to 1 and alternative ratios of 5.125 and 6.67 to 1. The alternative axle on this model is a B.M.C. two-speed with ratios of 5-85/813 to I or 5.125/7.13 to 1. The B.M.C. single-speed and two-speed are standard and optional, respectively, for the longer wheelbase 7-tonners, except that the standard ratio for the single-speed is 6.67 to 1 with 5-125 and 5-86 to 1 options. On the 7-ton tipper chassis the standard rear axle is a B.M.C. unit with an Eaton driving head, with ratios of 6.14 or 6.5 to 1. Optional for this model is a 13.M.C. axle with Eaton twospeed head and ratios of 6-14/8.54 to 1.

The B.M.C. axle with Eaton single-speed head is standard on the 8-tonner in the same ratios as available on the 7-tonner; alternative is the unit with Eaton two-speed head but with a ratio of 5-57/7.75 to 1 offered also. On the tractive unit, the B.M.C. axle with Eaton two-speed head is standard in a ratio of 614/8.54 to 1 with the ratio of 5.57/7-73 to 1 an option and the B.M.C. unit with singlespeed head is the alternative with a ratio of 6.14 to 1 andoptions of 6.5 and 5.57 to 1. All the two-speed axles have an air-operated ratio change mechanism.

The 5and 7-tonners and the tractive unit have the same front axle, although a heavier axle is fitted on the 8-tonner. Cam Gears high-efficiency 350 " Q " type steering, with a ratio of 25-5 to 1, is standard on the 5and 7-tonners and the tractive unit. Optional on these three models is a Cam Gears 300 " Q " box with hydraulic power assistance. The ratio of this box is 22.5 to 1, The power-assisted steering is fitted without option on the 8-tonner.

A feature of the new models is the brake system, which is air-assisted hydraulic, the components and layout on all four models being the same. Brake actuation at the front and rear axles is completely independent. There are in fact two completely separate systems, a divided air valve being operated by the brake treadle to allow compressed air from a dual reservoir to a dual actuator and tandem master cylinder. The dual actuator operates the tandem master as a single unit. The system is designed to cater for the most stringent requirements on the Continent, as it provides braking on all wheels at about one third of normal efficiency if one of the air circuits becomes inoperative. And, of course, the full brakes at one axle if the hydraulic circuit to the other develops a fault.

There is a dual air-pressure gauge included in the instruments, and there are also dual low-pressure switches which actuate a warning buzzer. A " tell-tale " piston in the dual air-pressure actuator is linked electrically to the buzzer and warns of excessive movement at the brake shoes to show the need for brake adjustment.

To meet the need for improved handbrake efficiency, airpressure assistance is incorporated in the mechanical linkage to the rear brakes. This takes the form of a diaphragm chamber acting on a relay lever in the line, pressure being supplied to this by a valve coupled to the brake linkage and allowing air from the rear chamber of the air reservoir.

a18 The tractive unit, the 8-tonner anc the 9-ft. 3-in.-wheelbase 7-tonner al have the same size brake units, them being 15.25 in. by 4.25 in. front an( 15.5 in. by 6 in. rear giving a total fric tional area of 573 sq. in. On the longei wheelbase 7-tonners the front brake!

are the same size but the rears art reduced from 6 in. to 5 in. wide and tht total frictional area is 520 sq. in. It the case of the 5-tonner, the drurr diameter at front and rear is 14 in and the shoe width at the front is 3.5 in and at the rear 5 in., total frictiona area being 415 sq. in. The brake unit are Lockheed on the 5-tonner and Girling on the othei models, being leading-and-trailing-shoe at the rear and two leading-shoe at the front axle in all cases.

Suspension is by semi-elliptic leaf springs, longer that were fitted on the models that the FJ chassis are replacing They are also wider than before, being 3 in. in all cases On all four models the front springs are 55 in. long, varia. tion for the different load capacities being in respect of tht number and thickness of leaves. On the three rigid chassi! the rear springs are 60 in. long with, again, a variation ir leaf thickness and number according to load rating whits. the rear springs of the tractive unit are 51 in. long.

nine-leaf, 38-in.-long helper spring is fitted in every cast to the rears and lever-type dampers are fitted as standar( to the front axle, with the same type optional at the rear Frame thickness for the range is 0-25 in. with 3 in flanges. Frame depth on the 5and 7-tonners is 9125 in at the centre, reducing to 6.5 in. at the rear. There is tht same rear depth of 6.5 in. on the 8-tonner frame; but tht centre section is 10.125 in. deep whilst on the tractive uni the frame depth is constant at front and rear, being 9-125 in Standard tyres on the three longer wheelbase 5-tonner are 7-50-20 (12-ply) with 8.25-20 (12-ply) the alternative 06 the 5-ton tipper the standard is 8.25-20 (14-ply) tyre!

with 8.25-17 (14-ply) alternative. On the 7-ton tipper tht standard tyres are 9.00-20 (14-ply) and this size with 9.00-2( (12-ply) are alternative on the longer wheelbase 7-tonner!

with 8-25-20 (14-ply) the standard. On the 8-tomier 9.00-2( (14-ply) are standard with 10.00-20 (14-ply) alternativt and the latter size is the standard for the tipper. In tht case Of the tractive unit, the standard and alternative tyre! fitted are exactly the same as on the longer-wheelbas4 7-tonners.

2 ft, 713 in. 5.ton 2 ft. 717 in, 7-ten 2 ft.13-625 in. 3-ton 2 ft. 8-75 in.

The electrical system is 12 V. with a 30 amp. d.c. genera tor and 4.5-in, co-axial starter. Two 6 V., 144 amp. hr batteries are mounted on the right-hand frame sidemembei behind the cab and a 30-way plug and socket connect chassis components and front lighting to the cab. A 5 and 7-way plug and socket connects the combination light ing switch to the main harness and other plugs are use( for connecting up the instrument cluster, oil-level indicatoi and heater. The wiper motor is a heavy-duty 5W. uni and a single high-note Windtone horn is fitted behind th. -front grille of the cab. Provision is made for a low-nott horn to be added if required.

Home market prices of the 12-ft. 7-in.-wheelbase F. models in chassis/cab form are: 5-tonner, £1,505; 7-tonner £1,550; and 8-tonner, £1,720. The 9-ft. 3-in.-wheelbast versions cost £15 less, whilst the 14-ft. 3-in.and 16-ft. 9-in. wheelbase models cost £10 and £25 more respectively it each case. The 8-ft.-wheelbase 18-ton tractive unit cost £1,592.