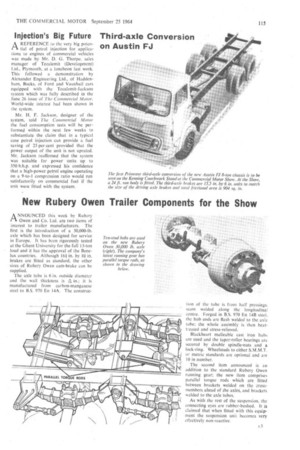

New Rubery Owen Trailer Components for the Show

Page 119

If you've noticed an error in this article please click here to report it so we can fix it.

A NNOUNCED this week by Rubery I-1 Owen and Co. Ltd. are two items of interest to trailer manufacturers. The first is the introduction of a 30,000-1b. axle which has been designed for service in Europe. It has been rigorously tested at the Ghent University for the full 13-ton load and it has the approval of the Benelux countries. Although 164in. by 811in. brakes are fitted as standard, the other sizes of Rubery Owen cam-brake can be supplied.

The axle tube is 6 in. outside diameter and the wall thickness is -76in.: it is manufactured from carbon-manganese steel to B.S. 970 En 14A. The construe

tion of the tube is from half pressings, scam welded along the longitudinal centre. Forged in B.S. 970 En 14B steel. the hub ends are flash welded to the axle tube; the whole assembly is then heattreated and stress-relieved.

Blackheart malleable cast iron hubs arc used and the taper-roller bearings are secured by double spindle-nuts and a lock-ring. WheelstudS to either S.M.M.T. or metric standards are optional and are 10 in number.

The second item announced is an addition to the standard Rubery Owen running gear; the new item comprises parallel torque rods which are fitted between brackets welded on the crossmembers ahead of the axles, and brackets welded to the axle tubes.

As with the rest of the suspension, the connecting eyes are rubber-bushed. It is claimed that when fitted with this equipment the suspension unit becomes very effectively non-reactive.