In the Transmission Line

Page 100

Page 101

If you've noticed an error in this article please click here to report it so we can fix it.

Recent Progress in the Design of Mechanism for Transmitting Power from Engine to Road Wheels is Briefly Reviewed

THE subject of transmission is, nowadays, rarely discussed without reference being made to various types of infinitely variable gear. A number of these appeared at the, Commercial Motor Show in November last, but the time has been too short since then for these new devices. to have fully emerged from the experimental stage.

Already, however, certain of them have been incorporated in specific makes of vehicle. A case in point is the Hobbs, which, installed in a Maudslay chassis, was described,

together with an account of its performance, in this journal last week. Another example is the Hayes, which is standardized in certain Austin cars. The developments in this direction which have taken place may be regarded as the first step to bigger things.

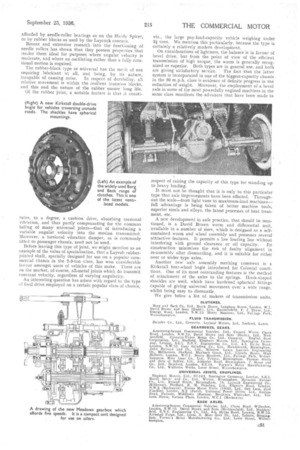

We described in our issue dated August 14, 1936, the interesting new Maybach box. This, although preselective and self-changing, is not infinitely variable, being of the step-up type. It is capable of affording eight ratios.

Turning now to gears in actual use on standard chassis, we find a slight advance in the trend towards increasing the number of ratios, also the continued use of the Wilson epicyclic unit. The addition of further ratios has been somewhat checked by the restrictions on weight, and, to some extent, by the improvements in engine performance, particularly in respect of flexibility and speed range.

In the main, transmission progress during the past two years has been of no greatly revalutionary nature. However, although no new principles have been adopted, many marked improvements of a detail nature, but of importance in their effect, have been made.

The smoothness of engagement in clutches has been enhanced by incorporating spring centres and better facing material, whilst carbon thrust bearings for the withdrawal mechanism have removed certain lubrication problems and eliminated a source of noise. An interesting development

of the friction clutch is the use, on a popular 3-tonner, of a clutch in which the action of the springs is supplemented by centrifugal force.

The fluid flywheel is now ineradicably established on powerful units for passenger work, and its general efficiency has been raised by detail modifications. As an example of the success of the hydraulic; ,torque converter, we quote the fact that a number of buses incorporating this means for automatically varying ne gear ratio is to be put into operation by the London Passenger Transport Hoard. That unquestionably represents a • progressive step.

With regard to the ordinary type of gearbox, it is noteworthy that synchromesh devices are being more generally adopted; in a number of cases a tendency is revealed to use gears in constant mesh, engagement being by sliding dogs. Improvements in design mainly comprise shorter, stiffer shafts, better-quality steels and more efficient tooth forms, whilst helical gears continue to enjoy popularity. There are more gearboxes affording a greater number than four gears, but the auxiliary box providing either an over-drivo or a further reduction is still in favour.

Passing on beyond the gearbox, we observe that the old type of universal joint has almost faded out of existence and that on almost every hand the universal movement afforded by needle-roller bearings as on the Hardy Spicer, or by rubber blocks as used by the Laycock concern.

Recent and extensive research into the functioning of needle rollers has shown that they possess properties that render 'them ideal for purposes where angular velocity is moderate, and where an oscillating rather than a fully rotational motion is required.

The rubber-block type or universal has the merit of not requiring lubricant at all, and being, by its nature, incapable of causing noise. In respect of durability, all relative movement is within the resilient trunnion blocks, and this and the nature of the rubber ensure long life.

Of the rubber joint, a notable feature is that .it consti tutes, to a degree, a cushion drive, absorbing torsional vibration, and thus partly compensating for the common failing of many universal joints—that of introducing a variable angular velocity into the motion transmitted. Moreover, a torsional vibration damper, as is commonly fitted to passenger chassis, need not be used.

Before leaving this type of joint, we might mention as an example of the value of specialization, that a Layrub rubberjointed shaft, specially designed for use on a popular commercial chassis in the 2-3-ton class, has won considerable favour amongst users of vehicles of this make. There are on the market, of course, all-metal joints which do transmit constant velocity, regardless of varying angularity.

An interesting question has arisen with regard to the type of final drive employed on a certain popular class of chas.sis, viz., the large pay-load-capacity vehicle weighing under 2* tons. We mention this particularly, because the type is certainly a relatively modem development.

On considerations of lightness, the balance is in favour of bevel drive, but from the point of view of the efficient transmission of high torque, the worm is generally recognized as superior. Both types are in general use, and both

are giving satisfactory service. The fact that the latter system is incorporated in one of the biggest-capacity chassisin the 30 m.p.h. class is evidence of definite progress in the reduction of weight. Moreover, the employment of a bevel axle in some of the most powerfully engined machines in the same class manifests the advances that have been made in

respect of raising the capacity of this type for standing up to heavy loading.

It must not be thought that it is only to this particular type that axle improvements have been effected. Throughout the scale—from light vans to maximum-load machines— full advantage is being taken of better machine tools, superior steels and alloys, the latest processes of heat treatment, etc.

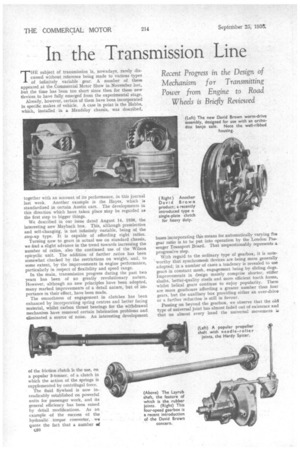

A new development in axle practice, that should be mentioned, is a David Brown worm and differential unit, i available in a number of sizes, which s designed as a selfcontained worm and wheel assemblyand possesses several attractive features. It permits a low loading line without interfering with ground clearance or oil capacity. Its construction minimizes the risk of faulty alignment in re-assembly after dismantling, and it is suitable for either over or under type axles.

Another new axle assembly meriting comment is a Kirkstall four-wheel bogie introduced for Colonial conditions. One of its most outstanding features is the method of attachment of the axles to the springs. Hook-shaped shackles are used, which have hardened spherical fittings capable of giving universal movement over a wide range, whilst being easy to dismantle.

We give below a list of makers of transmission units.