REDUCING FIERCENESS IN CLUTCHES.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Details of an Interesting Device which should Help the Driver.

APEW weeks ago we referred, in our pages dealing with recent Patents, to an interesting clutch construction in which a combination of the cone and plate patterns had been arranged. This form of clutch deserves further treatment because it has been designed with the object of ensuring

sweetness of engagement and doing away with the disadvantage of sudden gripping.

Certain forms of clutch are also apt to chatter during insertion, the reason usually being lack of alignment between the two members. As a matter cf fact, with the actual device which we are about to describe it is not essential that one of the clutches should be of the cone type, for the portion which performs the initial take-up can just as well be used in conjunction with a clutch of the single-plate pattern.

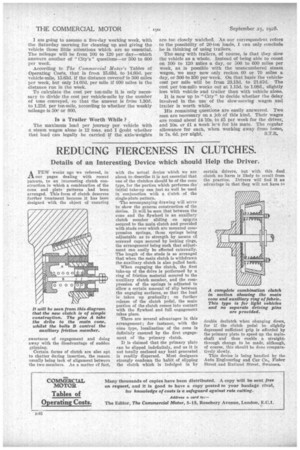

The accompanying drawing will serve to show the generat construction of the device. It will be seen that between the cone and the flywheel is an auxiliary clutch member sliding on spigots secured to the main clutch and provided with studs over which are mounted compression springs, these springs being adjustable as to strength by means of screwed cups secured by locking rings, the arrangement being such that adjustment can easily be effected externally. The length of the studs is so arranged that when the main clutch is withdrawn the auxiliary clutch is also pulled back.

When engaging the clutch, the first take-up of the drive is performed by a ring of friction material secured to the auxiliary clutch member, and the comPression of the springs is adjusted to allow a certain amount of slip between the engaging surfaces, so that the load is taken up gradually ; on further release of the clutch pedal, the main portion of the clutch comes into contact with the flywheel and full engagement takes place.

There are several advantages in this arrangement ; for instance, with the cone type, localization of the cone is definitely ensured by the first engagement of the primary clutch.

It is claimed that the primary plate can be slipped indefinitely, and as it is not totally enclosed any heat generated is readily dispersed. Most designers strongly condemn the habit of slipping the clutch which is indulged in by certain drivers, but with this dual clutch no harm is likely to result from the practice. Drivers will find it an advantage in that they will not have to

double declutch when changing down, for if the clutch pedal be slightly depressed sufficient grip is afforded by the primary plate to speed Up the main. shaft and thus enable a straightthrough change to be made, although, of course, this should be done comparatively slowly.

This device is being handled by the Auto Engineering and Car Co., Fisher Street and Rutland Street, Swansea.