Sweet

Page 30

Page 31

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

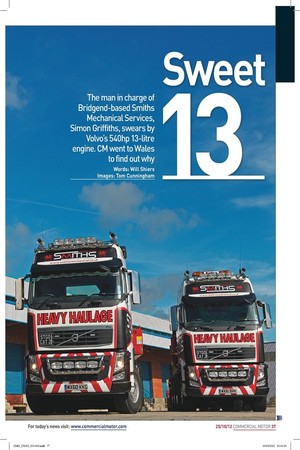

The man in charge of Bridgend-based Smiths Mechanical Services, Simon Griffiths, swears by Volvo’s 540hp 13-litre engine. CM went to Wales to find out why

Words: Will Shiers Images: Tom Cunningham

Think Volvo heavy haulage, and what two numbers spring to mind? Chances are you’re thinking of 16 and 750, right? After all, how can you possibly operate at GVWs in excess of 80 tonnes without 16 litres and 750hp under your right foot?

Well not so, according to Simon Griffiths, who heads up the heavy haulage division of Bridgend-based Smiths Mechanical Services. He swears by Volvo’s 540hp 13-litre engine. “We were going to buy FH16s, but the D13 is just such a cracking engine. And it’s in everything now, so parts are widely available too,” he says.

He goes on to explain that the torque levels between the 540hp D13 and the 600hp D16 (which is the highest horsepower you can specify with the all-important manual transmission) are similar too.

Griffiths adds: “I dare say if you stuck the two alongside each other maybe the 16 would pull away a little bit, but I wouldn’t have thought it would be a lot. If you put them over a hill the 16 might get to the top a minute before the 13, but so what? You might get a little bit more torque, but I’d rather get the fuel back these days.”

A great all-round truck

Griffiths is delighted with the fuel consumption of the three-strong Volvo FH13 heavy-haulage fleet. “The 150-tonner is averaging almost 5mpg,” he says, “and the 80-tonner will return mid-9s when it’s used on general haulage. It’s a great all-round truck.” The Smiths Mechanical’s heavy-haulage fleet consists of a 60-plate, 80-tonne FH13 540 6x2 Globetrotter with hub-reduction, a 12-plate 110-tonne 6x4 Globetrotter XL and a 150-tonne FH13 540 8x4 Globetrotter XL. Griffiths explains that the latter was bought as a 6x4, “and had a twin-tyre liftand steer-axle fitted under the centre” .

He explains that, whereas when you buy an 8x4 it comes with a single 9-tonne axle as the fourth axle, this has got a 13-tonne axle under it as well. “It’s a stocky little truck, and a lot shorter than what you can buy from the factory,” he says.

Head-turning capabilities

All are adorned with Kelsa light bars (top, bottom and rear) and have real head-turning capabilities. Indeed, the trio proved to be big crowd-pullers at this year’s Truckfest South West.

The only truck not to wear an iron mark logo on its grille is a 150-tonne Scania R560 – which is used as a back-up tractor. In the past, Smiths Mechanical Services

TYRES

In the last few months Smiths Mechanical Services has developed a strong relationship with Michelin, and Griffiths has only positive things to say about the French tyre maker.

“When we bought the 80-tonner new, it was specced with Bridgestones. But we found the drive-axle tyres only did 60,000km and then they were shot. So now we are converting everything over to Michelins. Both the 12-plate FH and the new Faymonville have been specced with them,” he says.

“Not only are they wearing well, but the super-singles look really good too.” ran a lot more Scanias, including a 1986 142, a 1988 143 and a 2000 164.

But whatever truck joins Smiths Mechanical’s fleet next, one thing that is for sure is that it will have a manual transmission. While Griffiths swears by the I-Shift for general haulage, and has indeed specified it on its 26and 44-tonners, he won’t touch it for heavy haulage. “At 44 tonnes, it’s great,” he says, “giving good fuel consumption and ease of use. But with heavy haulage we like the peace of mind that comes from knowing that, when you pick a gear, it’s staying in that gear.”

Manual vs I-Shift

He goes on to explain: “The problem comes where you hit a hill with 100-tonne onboard. With I-Shift, if you want to block change, you can’t. Let’s say you choose sixth, but really you should be in fourth, you have to click down twice on the hill. Whereas in the manual you can blockshift from sixth to fourth.” The company specialises in the movement of heavy plant, such as excavators, wheel-loaders and crushers, and does a lot of work for Volvo Construction. But it moves its fair share of larger loads too, and the day before CM’s visit a 5.5m-wide skid had been delivered to Barry docks on behalf of a local customer. “We self-escort 99% of our loads,” explains Griffiths, “but given the complexity of the job we required three policemen, a bike and a car for a minimum of five hours.” Historically Smiths ran predominantly King trailers, but these days it favours Faymonville. It has a fleet of threeand four-axle step-frames, and last month added an impressive six-axle step-frame double-extender.

Although the bulk of its work is in south Wales and the South West, Smiths Mechanical’s trucks can also be seen in central London. The firm has a contract with Crossrail, carrying 18m-long, 3.5m-wide rebar sections on three-axle powersteered extenders from Newport to Derwent Street, London.

Each of the trucks working on this contract have been fitted with cycle-friendly equipment, including sensors, left-turn warnings and a nearside camera. “We could have got away with Fresnel lenses on the nearside windows, but chose to invest in a camera instead. It cost about £500 to kit out each vehicle.” Smiths is a member of the Fleet Operator Recognition Scheme (FORS).

And for all the other work...

For lighter work Smiths has a pair of 44-tonne FHs, which pull step-frames on local work. A 26-tonne FM 6x2 is used to transport small plant.

Smiths Mechanical Services also has a contract with Breast Test Wales. As well as maintaining its seven-strong fleet of cancer screening trailers, it sites them with a dedicated 6x2 FM12.

The company employs six drivers. Griffiths tries to drive whenever he can, but these days it’s nowhere near as much as he would like. “I love driving, but because it’s a family business I all too frequently find myself in the workshop, or answering calls and pricing jobs instead,” he says.

With a stunning fleet like this it might come as a surprise to learn that the company doesn’t always find it easy to get new drivers. And no, it’s got absolutely nothing to do with Griffiths’ preference for the FH13 over the FH16. “We can get a driver just like that,” he says, clicking his fingers.

“The hard bit is finding a lorry driver who can also load a piece of plant, access equipment, or this, that and the other, and chain it down properly.” ■

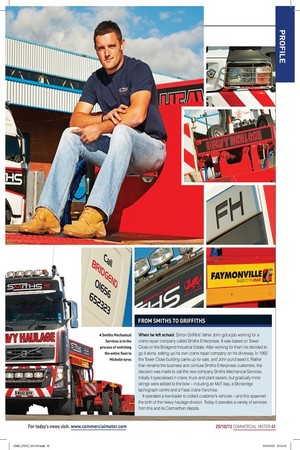

FROM SMITHS TO GRIFFITHS

When he left school, Simon Griffiths’ father John got a job working for a crane repair company called Smiths Enterprises. It was based on Tower Close on the Bridgend Industrial Estate. After working for them he decided to go it alone, setting up his own crane repair company on his driveway. In 1992 the Tower Close building came up for sale, and John purchased it. Rather than rename the business and confuse Smiths Enterprises customers, the decision was made to call the new company Smiths Mechanical Services. Initially it specialised in crane, truck and plant repairs, but gradually more strings were added to the bow – including an MoT bay, a Stoneridge tachograph centre and a Fassi crane franchise.

It operated a low-loader to collect customer’s vehicles – and this spawned the birth of the heavy-haulage division. Today it operates a variety of services from this and its Carmarthen depots.