AERODYNAMIC

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

ADVANTAGES

• Fuel price increases have their positive side in engineering terms. And the Gulf Crisis has again concentrated the minds of everyone involved in road transport on fuel efficiency.

However, The Department of Energy's co-ordinated fuel-saving project now attracting additional attention was up and running in June, however — long before the Iraqi invasion of Kuwait. And the operator involved, TNT Express, is reaping ever greater financial benefits as diesel fuel prices continue to rise.

It has been generally acknowledged for 20 years or more that a truck with a frontal area of 10m2 or more creates immense aerodynamic drag. Extra power and consequently extra fuel is needed to overcome that resistance to the vehicle's movement through the air.

Motorway speeds brought the problem into focus in the early 1970s helped by the cost pressures of the first world oil crisis. It was brought home to operators that where there is no wind the engine horsepower needed to overcome drag increases with the cube of the speed. As an example, for a given truck, a 28% increase in travelling speed, from say 70 to 90km/h means 65% more drag needing approximately 110% more power (and fuel) to overcome it.

That law of fluid dynamics cannot be altered by aerodynamic aids. But smoothing the flow of air over and around the vehicle, reducing the drag factor (Cd), brings down the baseline for the calculations.

Many of the wind deflectors sold in the 1970s were designed by small companies out to make a fast buck. The principal marketing criterion was one of aesthetics rather than true aerodynamic merit, the main requirement being a streamlined appearance. Attempts were made to register some designs, writs being threatened by at least one manufacturer which claimed to have patented the fiasic concept of mounting a deflector on the cab roof.

Aerodynamics and its fuel-saving potential, however, are now taken a lot more seriously, and hence tackled more scientifically, in line with other advances in vehicle technology.

Most attention quite justifiably has been paid to air management on articulated vehicles. A large proportion of attics are assigned to motorway tnuficing where average speeds and hence potential fuel savings, are high. And the shape of an attic, particularly the break in its outer surfaces between cab and trailer, where turbulence brings an additional drag penalty, gives immense scope for reductions in air resistance.

Research for the Department of Energy programme, carried out by Ricardo AS&A, has therefore been directed at long at-tics, taking into account the increase in permitted length at the beginning of this year from 15-5 to 16.5 metres overall.

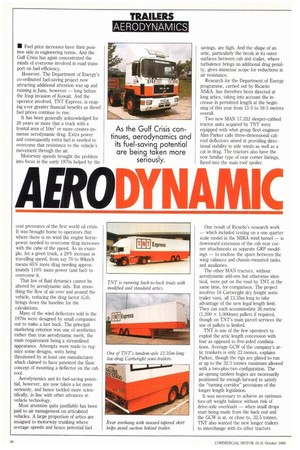

Two new MAN 17.332 sleeper-cabbed tractor units acquired by TNT were equipped with what group fleet engineer Alan Parker calls three-dimensional cab roof deflectors aimed at providing directional stability in side winds as well as a cut in drag. The tractors also have the now familiar type of rear corner fairings, flared into the main roof spoiler.

One result of Ricardo's research work — which included testing on a one quarter scale model in the MIRA wind tunnel — is downward extension of the cab rear corner attachments as separate GRP mouldings — to enclose the space between the wing valances and chassis-mounted tanks and auxiliaries.

The other MAN tractors, without. aerodynamic add-ons but otherwise identical, were put on the road by TNT at the same time, for comparison. The project involves 16 Cartwright dry freight semitrailer vans, all 13.35m long to take advantage of the new legal length limit. They can each accommodate 26 metric (1,200 x 1,000tnm) pallets if required, though on TNT's main parcel services the use of pallets is limited.

TNT is one of the few operators to exploit the attic length concession with four as opposed to five-wded combinations. Average GCW of the company's artic tnmkers is only 23 tonnes, explains Parker, though the rigs are plated to run at up to the 32.5 tonnes maximum allowed with a two-plus-two configuration. The air-sprung tandem bogies are necessarily positioned far enough forward to satisfy the "turning corridor" provisions of the longer length legislation.

It was necessary to achieve an optimum fore-aft weight balance without risk of drive-axle overloads — when small drops start being made from the back end and the GCW is at, or close to, 32.5 tonnes. TNT also wanted the new longer trailers to interchange with its other tractors and give improved operational flexiblity.

A 1. 35m king-pin setting was therefore specified — a compromise position suiting both the new 3.5m-wheelbase MANs and the bulk of the existing TNT tractive unit fleet, which includes Iveco, ERF and Renault chassis.

Modifications to improve the aerodynamics of eight of the 16 Cartwright semitrailer vans are considerable. But on the front bulkhead, where fundamental alterations might have been expected, the only variation is an add-on airflow moulding along the top edge. This serves to increase the corner radius without encroaching on load-space.

The body's front corner pillars are of 150Enm radius — less than the 250mm optimum often quoted as the realistic ideal from a drag point of view. But the larger radius would have prevented squareedged pallet loads or boxes being stacked into the front corner of the trailer. And in any case, the tractor cab airflow attachments have been tailored precisely to the known dimensions (notably the 3.8m overall height) and shape of the Cartwright trailer.

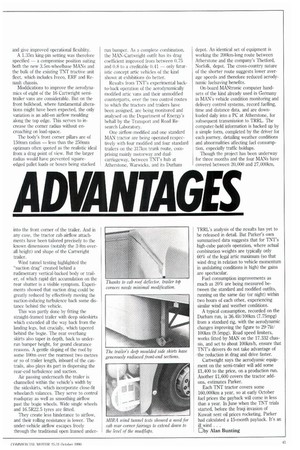

Wind tunnel testing highlighted the "suction drag" created behind a rudimentary vertical-backed body or trailer, of which rapid dirt accumulation on the rear shutter is a visible symptom. Experiments showed that suction drag could be greatly reduced by effectively moving the suction-inducing turbulence back some distance behind the vehicle.

This was partly done by fitting the straight-framed trailer with deep sideskirts which extended all the way back from the landing legs, but crucially, which tapered behind the bogie. The rear overhang skirts also taper in depth, back to underrun bumper height, for gound clearance reasons. A gentle sloping of the roof by some 100m over the rearmost two metres or so of trailer length, inboard of the cantrails, also plays its part in dispersing the rear-end turbulence and suction.

Air passing underneath the trailer is channelled within the vehicle's width by the sideskirts, which incorporate close-fit wheelarch valances. They serve to control roadspray as well as smoothing airflow past the bogie wheels. Wide single wheels and 16.5R22.5 tyres are fitted.

They create less hinderance to airflow, and their rolling resistance is lower. The under-vehicle airflow escapes freely through the traditional open framed under run bumper. As a complete combination, the MAN-Cartwright outfit has its drag coefficient improved from between 0.75 and 0.8 to a creditable 0.41 — only futuristic concept artic vehicles of the kind shown at exhibitions do better.

Results from TNT's experimental backto-back operation of the aerodynamically modified artic vans and their unmodified counterparts, over the two control routes to which the tractors and trailers have been assigned, are being monitored and analysed on the Department of Energy's behalf by the Transport and Road Research Laboratory.

One airflow-modified and one standard MAN tractor are being operated respectively with four modified and four standard trailers on the 317km trunk route, comprising mainly motorway and dualcarriageway, between TNT's hub at Atherstone, Warwicks, and its Durham depot. An identical set of equipment is working the 200Iun-long route between Atherstone and the company's Thetford, Norfolk, depot. The cross-country nature of the shorter route suggests lower average speeds and therefore reduced aerodynamic fuelsaving benefits.

On-board MANtronic computer handsets of the kind already used in Germany in MAN's vehicle condition monitoring and delivery control systems, record fuelling, time and distance data, and are downloaded daily into a PC at Atherstone, for subsequent transmission to TRRL. The computer-held information is backed up by a simple form, completed by the driver for each journey, detailing weather conditions and abnormalities affecting fuel consumption, especially traffic holdups.

Though the project has been underway for three months and the four MANs have covered between 20,000 and 27,000km, TRRL's analysis of the results has yet to be released in detail. But Parker's own summarised data suggests that for TNT's high-cube parcels operation, where actual combination weights are typically only 60% of the legal artic maximum (so that wind drag in relation to vehicle momentum in undulating conditions is high) the gains are spectacular.

Fuel consumption improvements as much as 20% are being measured between the standard and modified outfits, running on the same day (or night) within two hours of each other, experiencing similar wind and weather conditions.

A typical consumption, recorded on the Durham run, is 36.41it/100km (7.75mpg) from a standard rig, with the aerodynamic changes improving the figure to 29.71it/ 1001un (9.5mpg). Road speed limiters, works fitted by MAN on the 17.332 chassis, and set to about 100km/h, ensure that TNT's drivers do not take advantage of • the reduction in drag and drive faster.

Cartwright says the aerodyamic equipment on the semi-trailer will add some £1,400 to the price, on a production run. Another 11,600 covers the tractor addons, estimates Parker.

Each TNT tractor covers some 160,0001cm a year, so at early October fuel prices the payback will come in less than a year. In June when the TNT trials started, before the Iraqi invasion of Kuwait sent oil prices rocketing, Parker had calculated a 15-month payback. It's an ill wind . . .

Eby Alan Bunting