• You can tell operators that if they did everything

Page 120

Page 121

Page 122

If you've noticed an error in this article please click here to report it so we can fix it.

it says on the service schedule they wouldn't have half the problems they do." So said one of the fitters at Mercedes distributor Sparshatts of Kent when we went to their workshops on the Eurolink Industrial Estate at Sittingbourne to go through the servicing of the Mercedes 1625.

When we asked for examples, nearly all of them came from items on the schedule which start "Check security" or "Check operations and security". Typical are things like propshaft flange nuts, gearchange linkages, filters and feeds from reservoirs.

The Mercedes 1625 is a good example of a truck on which the maker has paid a lot of attention to reliability and to making routine servicing easier. Much of the servicing schedule consists of "check" items, but the people at Sparshatts emphasised that this means more than just looking at them. For example, the propshaft flange nuts should always be checked with a torque wrench.

It was also emphasised that when the service is finished, anything which has been disturbed, such as a filter, should be checked again after the engine has been run in.

1 Things tend to be a little cramped around the accelerator linkage, and Sparshatts has found one or two examples where the rod link has been chafing against one of the coolant hoses. Particularly, this is likely to occur if a "pattern" hose has been used where the moulded bends are not quite the same as on a genuine Mercedes hose.

2 There are two exhaust brakes on the Vee engine. When the seals wear there is sometimes an air leak and the valves do not close fully. You need two people to check for this, one to operate the control in he cab and another to listen for any hissing of leaking air when the cylinders are under pressure. 3 The range change lever on the gearbox is a good example of a "check" item. If the pinch bolt is not tight, the lever can ride up on its splines, and if it becomes too loose the splines can be damaged, which can be an expensive repair.

...,................ --„....,..,

4 Keep the telescopic Part of the gearchange linkage well greased. It is exposed under the cab, and if the sliding tubes become stiff there is a danger that things can become bent when you lower the cab. Never use the link as a handhold to climb on the engine. 5 There is a water trap just in front of the air reservoirs which has a release valve at the bottom. Some operators let the water out of the bottom regularly but never remove the bowl for cleaning. The result is it gets clogged like this one. It should be cleaned at every service.

6 The large air filter element should be taken out at every service and cleaned off with the compressed air line. The air line should always be used from the inside of the filter. If you blow on the outside you only drive the dirt deeper in. 7 The reservoir for the power steering lives under the front grille and there is a small dipstick alongside the filler for checking the level. It is not the easiest reservoir to top up, and a can with a long spout or a long necked funnel is a great help.

8 The bolts on the propshaft flanges are always checked by Sparshatts using a torque wrench. If they are tightened unevenly there is a chance that some will work loose and lead to vibration problems. 9 Sparshatts has come across several examples of operatormaintained trucks where no one has looked at the propshaft centre bearing until the rubbers have disintegrated. On one occasion, lack of preventive checking led to an expensive repair bill.

1 There are two pressure

caps on the radiator header tank. Only the one on the extended neck should be removed for topping up, and even this should be removed carefully. The second cap is used for pressure checking only and is wired to remind fitters not to touch it.

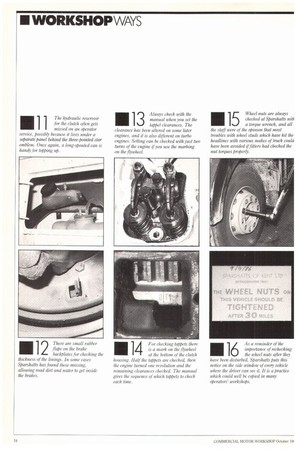

1 The hydraulic reservoir

for the clutch often gets

missed on an operator service, possibly because it lives under a separate Panel behind the three-pointed star emblem. Once again, a long-spouted can is handy for topping up.

2 There are small rubber

flaps on the brake backplates for checking the thickness of the linings. In some cases Sparshatts has found these missing, allowing road dirt and water to get inside the brakes.

13 Always check with the manual when you set the tappet clearances. The clearance has been altered on some dater engines, and it is also different on turbo engines. Setting can be checked with just two turns of the engine if you use the marking on the flywheel.

For checking tappets there is a mark on the flywheel at the bottom of the clutch housing. Half the tappets are checked, then the engine turned one revolution and the remaining clearances checked. The manual gives the sequence of which tappets to check each time.

14

1 Wheel nuts are always

checked at Sparshatts wit)

a torque wrench, and all the staff were of the opinion that most troubles with wheel studs which have hit the headlines with various makes of truck could have been avoided if fitters had checked the nut torques properly.

1 As paortreami in theroecf htlei ce king

the wheel nuts after they have been disturbed, Sparshatts puts this notice on the side window of every vehicle where the driver can see it. It is a practice which could well be copied in many operators' workshops.