Wonderful Show trimmer models

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

The same engineering trend is repeated time and again at the NEC: kerb weights are coming down. By Graham Montgomerie

ANY VISITOR to the NEC who has been on a desert island recently could be forgiven for not noticing that the UK commercial vehicle industry is in the middle of a massive slump. There is certainly little evidence of this at Birmingham with a tremendous display of chassis and components being on show.

In spite of the intriguing possibilities of the Armitage Report, most manufacturers have still made a determined effort to get some weight out of their products and this weight-saving trend is repeated over and over again throughout the exhibition.

At the time of writing (on the trade days) the Show would seem to be more successful from the operators' point of view with far less of the overcrowding which marred the 1978 show.

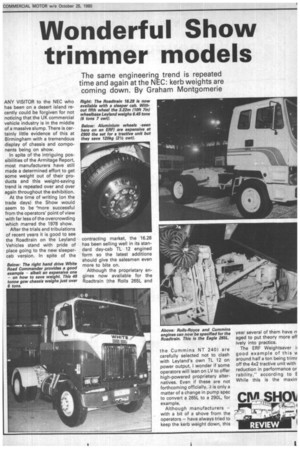

After the trials and tribulations of recent years it is good to see the Roadtrain on the Leyland Vehicles stand with pride of place going to the new sleepercab version. In spite of the contracting market, the 16.28 has been selling well in its standard day-cab TL 12 engined form so the latest additions should give the salesmen even more to bite on.

Although the proprietary engines now available for the Roadtrain (the Rolls 265L and the Cummins NT 240) are carefully selected not to clash with Leyland's own TL 12 on power output, I wonder if some operators will lean on LV to offer high-powered proprietary alternatives. Even if these are not forthcoming officially, ;t is only a matter of a change in pump spec to convert a 265L to a 290L, for example.

Although manufacturers with a bit of a shove from the operators have always tried to keep the kerb weight down, this

year several of them have naged to put theory more eff ively into practice.

The ERF Weightsaver good example of this ‘A around half a ton being trimr off the 4x2 tractive unit with reduction in performance or rability," according to E While this is the maxirr

Tight reduction achieved with -le Gardner models only, evertheless the other models in ERF range have also beneted from the slimming exerse. There have been no dramac areas of weight reduction, rerely a logical commonsense pproach which has saved a few los here and there adding up to useful total.

The largest chunks of weight hich have been eliminated are the axle and suspension areas. must be stressed, however, at ERF has down-plated the .hicle to 36 tonnes gew. So it )uld be argued that it is not a ir comparison with the original .Series chassis. Tailoring the :le specification to suit the wer gcw by switching from the 35 to the D65 Kirkstall axle has oduced a saving of 113kg 50IW while specifying tapered at springs instead of the -evious multi-leaf assembly ved a further 90kg (2001b). The Show model of the B:ries tractive unit is a 36R2 lich as the type number sug!sts has the 265L Rolls engine ted and also, what is possibly ultimate weight-saving ploy the moment, aluminium alloy -eels. Although they make a bstantial contribution to the N weight of around 51/2 tons, many operators are weight nscious enough to part with 00 for a set of these wheels? eduminium crops up in a mber of areas on the ERF in'ding the fuel tank, front mper and some bracketry. 3eddon Atkinson is another inufacturer to have a show assis fitted with aluminium leels, in this case the recently nounced 401 which to my as now looks very Americand indeed with its new front Ile and IH symbols on the ors.

The aluminium wheels save around 20kg (451b) per wheel which adds up to a useful 120kg (2651b) per chassis. However, at £900 . .

As a matter of interest this is the first time that a Gardner-engined chassis has not been featured on the Seddon Atkinson stand at a Motor Show although I was assured that this is of no political significance whatsoever!

The European heavy lorry industry cannot teach the Americans anything about the use of aluminium — they have been using it for years to great effect. The White Road Commander 2 is a classic example of how the US industry has pioneered the lightweight path, although it must be admitted that America has had one temendous advantage in that aluminium is very cheap over there compared to its price in Europe.

Consider the White for a moment. The cab is all aluminium which is also used for the bumpers, the inlet air trunking, the fuel tanks and the spring hanger brackets. This all contributes to the very low kerb weight of 6.18 tonnes (6 tons 2cwt) including fifth-wheel. If that does not appear particularly light, it should be remembered that it is a sleeper-cab chassis fitted with a 242kW (325bhp) Caterpillar engine, twin fuel tanks with a capa city of 660 litres (145ga1) and plated for operation at 49 tonnes gross.

Although aluminium makes a significant contribution to the weight saving on the White, the chassis also plays an important part as it is from high-tensile steel which, although expensive, allows the same strength requirements to be met using a shallower frame.

This is the first time that the right-hand-drive White has been seen and although the particular show model was built in Virgi nia, future chassis will be assembled at Bromborough on Merseyside. The list price for the Road Commander 2 is £32,500 with the rest of the driveline spec comprising a Fuller RTO 9513 gearbox and an Eaton 30427 axle.

Volvo sprang a surprise with a last minute announcement of a further variant in the F7 sixwheeler range. This is the F7 6x4 L-ride which has been developed mainly for on-highway operation while still giving a good off-road performance and it has been designed with weight saving very much in mind.

The main difference between this latest chassis from Volvo's Scottish plant and the existing Tride 6x4 is in the bogie suspension. With the L-ride, this is a four-spring design using conventional slipper-ended leaf springs connected via a rocking balance beam.

Comparing the 3.6m (lift 10in) wheelbase L-ride and T ride six-wheelers, for example, there is a weight saving of over a 'ton. This is not due entirely to the change in suspension however. With the L-ride model there is no inner liner to the chassis and the rear cross-member is lighter as the suspension loads are fed into the chassis in a different place with the four spring suspension.

Still on the weight-saving theme, Rockwell wedge brakes replace the S-cam brakes of the T-ride version and the fuel tank is smaller — 200 litres compared with 300 litres (44 v. 66 gal).

Volvo intends to produce the L-ride F7 alongside the current T-ride version at Irvine with the new chassis aimed at operators involved in sand/gravel haulage, mixers and tankers. In other words, the L-ride lightweight F7 is being produced to compete head on with Leyland's Bison — something the "original" 6x4 Volvo could not do on kerb weight as its 71/2 tonnes plus would not permit, say, a 6cum (7.8cuyd) mixer body within the legal weight limits.

Surprisingly perhaps the aluminium fuel tank of the F7 trac

tive unit is not used on the 6x4. Whether 200 or 300 litres, the tank is made of steel.

I mentioned earlier the 3.6m wheelbase Volvo and it is worth pointing out at this stage that Gothenburg (or Irvine?) has decided to change its definition of wheelbase from inner axle spread to the more usual UK method of front axle to mid-bogie. If Fodens will switch from outer axle spread then the whole industry will understand perfectly what it means by "wheelbase."

Weight saving around the vehicle is something that several manufacturers have been paying only lip service to. It is all very well trimming off the odd kilo by fitting, say, an aluminium bumper, but this does not amount to much when compared with the six tons odd of the complete tractive unit or even eight tons plus of an 8x4 rigid.

The innovative company of Motor Panels (Coventry) Ltd has certainly gone overboard to trim more than a few kilos from the vehicle or rather from the parts of the lorry over which it can exert an influence for Motor Panels do not, obviously, make engines or gearboxes.

The new Motor Panels cab is constructed entirely from aluminium alloy, which the company claims results in a cab which is one third the weight of a conventional steel cab. The clever part about this particular design is that the same tooling can be used to produce both aluminium or steel pressings. The pressure required is different but the various corner radii are the same as the depth of draw was taken into account at the design stage.

Taking weight out of the cab structure is one thing, but there is a lot more to a commercial vehicle cab than just the shell so Motor Panels have gone a stage further and lightened the furniture as well. The seats, which have been built by Bostrom, are of tubular construction covered in an open-weave material which apart from the obvious weight saving should also help to keep the driver cool. Although the material looks flimsy Motor Panels claim that while it is very strong, if something does get ripped or give way then it is easy to replace.

The Motor Panels cab also manages to pack two bunks into the depth of a standard day cab albeit with a little help in the vertical direction from a movable roof panel which doubles up as wind deflector. "Doubles up" a useful expression to apply the seat backs as well, as, wht tilted forward, they provide tv sections of the lower bunk with separate tubular structure heir slotted in for the middle piec The upper bunk hinges down one piece from the rear bul head.

The engine manufacture have made a significant cont bution to the weight-savir campaign with Rolls-Royce, f example, trimming around 601 (130Ib) on average from its e gines. The 290L Eagle is a typic example of this.

During the production d velopment of art engine, varicti bosses and lugs are incorp rated into the basic found drawings for the heads at crankcases for ease of handlir on the production line. The bosses and lugs, etc, have a ht rible habit of remaining even the production techniques ha altered. Thus Rolls-Royce h eliminated all these unnecessa appendages with the current e gine series saving around 18 (40Ib) on the crankcase alone the 290L.

Still on the slimming kick, ti flywheel housing is now a gre ity die-cast alloy unit which, conjunction with a reprofill sump and a slightly smaller capacity, has resulted in a sigi ficant weight saving.

Rolls-Royce has been vs successful just recently. Sh UK, for example, placed ords for 100 ERF tractive uni mered by the 265L as well as r the first seven Seddon Atkinm 401s to be built with the ime power unit. Rolls is cerinly very confident about the eight-saving possibilities of e Eagle range currently claimg a 85kg (1811b) weight advange with the 290L against the rmmins E290.

The American company has e new E400 engine on its stand king the E-Series concept up to 18kW (400bhp) gross. It shares ost of the features of the fami r E290/350/370 models which ntinue in production.

Remembering the effort which immins put into getting eryone to drop the "Big Cam" 'e and calling the engine series

"E"-range, it is interesting to ,te that DAF is doing a very nilar thing with its "Big E" verm of the 1160 turbocharged d charge-cooled engine. This gine is now reduced in speed 1,800rpm with a resultant imDvement in torque to 1,260Nm

lbft). It is at the NEC in the est 2800 chassis and takes er from the original DKS enled model as top of the Dutch mpany's range, according to F.

_ight weight has for a long ie been one of the major adltages of the Gardner engine ige so the strike hit company 3 not had a lot to do in that ection. The uprated 8LXC is ine among current new enes in that its engine speed s actually been increased ainst the trend albeit by only .pm.

he increase in power has not an achieved by the change in dine speed alone. Gardner has incorporated a number of modifications into the eight-cylinder engine mainly to the head, valves, guides and inserts. As some of these changes relate to major components it is not really practical from a cost point of view for an operator to consider converting his 8LXB to "C" specification. It could be done from an engineering point of view but the financial side would not make a great deal of sense.

Representing the top end of the torque scale at this year's Show is the Scania DS14 engine fitted to the new bonneted T142E which is making its UK debut. The Show model is a 6x4 tractive unit intended for indi visible load work. The turbocharged V8 engine produces no less than 1,480Nm (1090 lbft) of torque.

As Scania is a comparatively small company as far as volume vehicle production is concerned it would be unrealistic to expect the factory to have produced a new cab for the T-range alone. Thus the cab on the Show model is worth a close look as it is vir

For many years, the UK 32-ton weight limit has meant two types of tractive unit in this sector — one for the operator wanting a 32-tonner pure and simple like the Leyland Buffalo or the old F86 and the other category for the 3 8/4 0-tonne machine which at the end of the day could stiil only operate at the same 32 tons gross.

Mercedes goes one step further and divides the topweight class into four sectors based on engine horsepower: 180 to 220bhp (accounting for 14 per cent of the total), 221 to 260bhp (45 per cent), 261 to 300bhp (34 per cent), with the 300 horsepower plus sector accounting for the remainder.

This is the reason behind the Mercedes move to two separate engine ratings for the familiar naturally aspirated V8 unit from the 1626S. Now available at 184kW (247bhp) and 206kW (276bhp) Mercedes hope to cover both of the more popular power categories with the 180 to 220 horsepower category already covered by the 1619 and the 300 plus sector by the V10 chassis. Based on current market analysis figures, the Daimler Benz prediction is that the sales split between the two new models will be 50/50.

Perkins have chosen the 1980 Show to announce that the tur bocharged TV8. 640 engine is to be supplied to ERF for the M Series 24-tonner. Derated to 162kW (218bhp) at 2200rpm, the Perkins will be offered along with the VT 555 Cummins.

If one needed an example to illustrate how the importers gradually develop their ranges in the UK by starting at the top with the long-haul "glamour" machines and then gradually moving down the weight scale, then the Renault and IVECO stands illustrate the point. Despite all the recent upheavals, both home and abroad, the IVECO stand comprises a full complement of Fiat and Magirus models with the main item of interest being the new Fiat 100F 13 for operation at 10.6 tonnes gross.

This latest addition to the IVECO range resembles the lighter Fiat/Magirus models as far as the cab is concerned and fills a gap in the current range.

Likewise Renault started at the top end and has worked downwards, and again like IVECO it has done so by starting off with two separate marques. Like IVECO with Fiat and Magirus, the same applies to Renault with Saviem and Berliet. At the NEC, the original names have disappeared with all the chassis being designated Renault.

On the light van scene, the new Renault Trafic and Master ranges present a major surprise in that they are both available with the option of front or rearwheel drive. Previously manufacturers have been very for or very against one particular dri

veline layout, depending of course upon the production and design constraints of the factory.

Thus in recent years we have had both IVECO and Daimler Benz extolling the virtues of rear-wheel drive both from the point of view of the ride, handling, ease of getting in and out, ease of maintenance and so on and so on. As far as DaimlerBenz was concerned their view was made all the more credible by the fact that the company had inherited a front-wheel-drive design of light van during the political and financial machinations of the Hanomag Henschel takeover. Despite all the theoretical advantages of the low-loading height and opportunities for bodybuilding ingenuity, the engineers of the Three Pointed Star opted very, very firmly indeed for a front-engine, rear-wheeldrive layout for the latest Bremen range.

So as far as Renault is concerned does this mean that the vast state owned company is hedging its bets? I certainly do not think so because Renault is obviously very French and as such is influenced by its home market. In the typical light van ranges in France, no less than 80 per cent are front-wheel drive. Renault is finding, however, that when operators move up the weight scale they tend to move towards a more "conventional" driveline, ie with the rear axle doing the work.

With a large predominanti fwd home market to satisfy, RE nault has to provide such a dr vane. But with an eye to th future {and to the export ma kets) the Regie is not putting a its corporate eggs into one bar ket. It remains to be seen if th choice of front or rear-wher drive will continue for very lorq However, while it does the U operator will have the choice

The Trafic fwd version will b available in this market fror February next year closely fo lowed by the rear-wheel-driv version. The model spans th 800 to 1,000kg (16 to 20cw payload category and is avai able with a choice of three er gines (two petrol and one diese with Renault playing the mark( to see what happens in this pa ticular area.

By the middle of 1981 the Ma: ter (1,400 to 1,800kg payloar will be available in the UK, aga in front-wheel-drive form to sta with.

To maximise the loadir height advantage of the fror wheel-drive configuration, R nault has incorporated a sti into the dead axle which h allowed a floor height of or 460mm (18in). This low loadii height is of course one of t theoretical advantages of front-wheel-drive design, b then that is what Daimler-Be said some years ago when exti ling the virtues of the 306D.

Renault is obviously ve serious about attacking the market in this particular weig sector which currently accour for some 120,000 units per ye; I will be very interested to see which of the various front/rearwheel-drive, petrol/diesel options is preferred by the UK operator.

As an after-thought, does anyone else see a styling resembance between the Master and trafic and the 1973 light van reaulting from the politically 'raught union between Fiat. and 2itroen? Be that as it may the lew Renault range is currently oeing produced in no less than 77 different versions in France.

MAN-VW has a particularly ineresting design exercise on >how in the shape of a fouryheel-drive version of the Volksyagen LT. This is not a Wolfs)urg production option but a :onversion job carried out by JAM Special Vehicles of slewton Abbott whereby a con,entional LT rear axle is rebuilt o form a steering drive axle.

The vehicle on show is very nuch a prototype, but nevertheass MAN-VW is hoping to go ito production by March '81 with about 10 units per month ising to 30 to 40 per month vithin two years. It will be availble with all the current LT opons, ie, integral van, chassis ab and crew cab and will be imed predominantly at the lunicipal market. In particular IAN-VW will be going for the x4 ambulance market as a luch cheaper alternative to the ange Rover.

At current prices the MAN-VW x4 is expected to sell at around 11,500 in high-top integral van )rm which the company esti)ates is some E1,500 cheaper Lan the equivalent Leyland prouct. Another point in favour of le LT is that it does not require ny special bodywork to fulfil le function of an ambulance. Not before time, the design of the commercial vehicle suspension system has received a shot in the arm. Although air suspension is conspicuous by its absence at the NEC (cost?), rubber suspension and carbon-fibre leaf springs more than make up for this.

The suspension of a heavy lorry has not changed very much since Adam was a lad. Multileaf steel (and thus heavy) leaf spring systems are the order of the day.

Fodens (I can't bring myself to call it the Sandbach Engineering Company) took the plunge some time ago by venturing into the rubber suspension field and it looks as though the move has paid off. Rubber suspension was introduced at Tipcon last year as an option on the double-drive Foden rigids — it is now standard on the 6x4 and, while still an option on the eight-wheeler, around 90 per cent of the orders are for this type of suspension.

The original Foden/Rydewell rubber suspension (the FR system) was a transverse layout and while this worked satisfactorily it was impossible to incorporate the system with a 1.38m (4ft 6in) bogie spread because of the lack of space. Thus Fodens developed their own system (the FF) where the rubber suspension elements are mounted longitudinally which gets around this space problem. The Foden rubber suspension is currently available with both the Foden and the Rockwell SQRHD bogies.

The obvious advantage of rubber suspension is its total lack of maintenance, but other advantages include weight saving (again!) with a typical figure over a conventional system be

ing around 17 5kg (385 lb). According to Fodens, ride and handling are also improved as is tyre wear.

At the last NEC show, in 1978, Bedford exhibited the "Long Haul" aerodynamic styling exercise based on a TM tractive unit. This year the company has done the same thing, but uses the new TL as a base.

While not wishing to pour cold water on the efforts of the Bedford designers, I do wish that someone would come up with a kerb weight for the TL Aero. The same thing happened two years ago with the Long Haul when no weight figure was forthcoming. I appreciate that such an exercise Below: The Ogle Design styling exercise on the Leyland C40 cab uses television cameras in the doors instead of conventional mirrors. The screens are situated above the windscreen in front of the driver. is often very much of a showtime gimmick, but nevertheless there are some useful features incorporated which could be of use to today's operators who would be justified in inquiring as to the possible weight penalty to be balanced against any possible fuel savings because of decreased drag.

In the transmission field the scehe is somewhat depressing. For a number of years now, people have been predicting, an increase in the number of semi!fully automatic gearboxes on the road. This was predicted regularly to the point of boredom, but it never actually happened. This year, not only has there not been an increase in the number of chassis so equipped, the concept of a non-manual gearbox seems to have disappeared altogether.

One exception is a combined Eaton/Brockhouse torque converter system which is not on anyone's stand but is fitted to a Gulf Oil Seddon Atkinson 400 in the demonstration park.