Savings and all that gas

Page 68

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

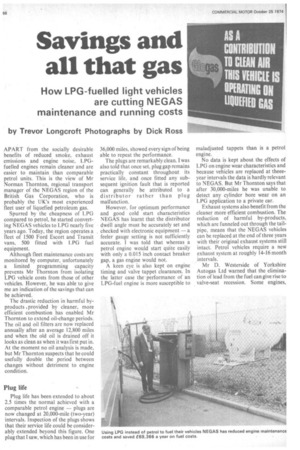

How LPG-fuelled light vehicles are cutting NEGAS maintenance and running costs

by Trevor Longcroft Photographs by Dick Ross

APART from the socially desirable benefits of reduced smoke, exhaust emissions and engine noise, LPGfuelled engines remain cleaner and are easier to maintain than comparable petrol units. This is the view of Mr Norman Thornton, regional transport manager of the NEGAS region of the British Gas Corporation, who is probably the UK's most experienced fleet user of liquefied petroleum gas.

Spurred by the cheapness of LPG compared to petrol, he started converting NEGAS vehicles to LPG nearly five years ago. Today, the region operates a fleet of 1500 Ford Escort and Transit vans, 500 fitted with LPG fuel equipment.

Although fleet maintenance costs are monitored by computer, unfortunately a limited programming capacity prevents Mr Thornton from isolating LPG vehicle costs from those of other vehicles. However, he was able to give me an indication of the savings that can be achieved.

The drastic reduction in harmful byproducts . provided by cleaner, more efficient combustion has enabled Mr Thornton to extend oil-change periods. The oil and oil filters are now replaced annually after an average 12,800 miles and when the old oil is drained off it looks as clean as when it was first put in. At the moment no oil analysis is made, but Mr Thornton suspects that he could usefully double the period between changes without detriment to engine condition.

Plug life

Plug life has been extended to about 2.5 times the normal achieved with a comparable petrol engine — plugs are now changed at 20,000-mile (two-year) intervals. Inspection of the plugs shows that their service life could be considerably extended beyond this figure. One plug that I saw, which has been in use for 36,000 miles. showed every sign of being able to repeat the performance.

The plugs are remarkably clean. I was also told that once set, plug gap remains practically constant throughout its service life, and once fitted any subsequent ignition fault that is reported can generally be attributed to a distributor rather than plug malfunction.

However, for optimum performance and good cold start characteristics NEGAS has learnt that the distributor dwell angle must be accurately set and checked with electronic equipment — a feeler gauge setting is not sufficiently accurate. I was told that whereas a petrol engine would start quite easily with only a 0.015 inch contact breaker gap, a gas engine would not.

A keen eye is also kept on engine timing and valve tappet clearances. In the latter case the performance of an LPG-fuel engine is more susceptible to maladjusted tappets than is a petrol engine.

No data is kept about the effects of LPG on engine wear characteristics and because vehicles are replaced at theeeyear intervals the data is hardly relevant to NEGAS. But Mr Thornton says that after 30,000-miles he was unable to detect any cylinder bore wear on an LPG application to a private car.

Exhaust systems also benefit from the cleaner more efficient combustion. The reduction of harmful by-products, which are funneled out through the tailpipe, means that the NEGAS vehicles can be replaced at the end of three years with their original exhaust systems still intact. Petrol vehicles require a new exhaust system at roughly 14-16 month intervals.

Mr D. Westerside of Yorkshire Autogas Ltd warned that the elimination of lead from the fuel can give rise to valve-seat recession. Some engines, especially those used on fast motorway work, need to be fitted with hardened valve seats to overcome the problem. On a four-cylinder head this can be carried out for about £12.

Mr Thornton said that his vehicles showed no signs of irregular valve-seat wear. and that he has in fact reduced the occurrence of valve trouble by about two-thirds, again compared to similar petrol engines.

The Ford vans are delivered complete with carburetters and fuel pump, etc, and the LPG system is added, giving the company the choice of either petrol or LPG operation at the flick of a switch. But vehicles are not supplied with petrol to reduce the risk of pilfering. Also when vehicles are due to be replaced the LPG equipment can be transferred to the new vehicles and the old vehicle sold without making any modifications to it.

The system, which costs £170, comprises three main components: the tank, the evaporator/ regulator and the venturi. The tank can be located in any convenient position, but in the Transits 1 saw they were just behind the dyiver's seat — the filler point being a small panel incorporated in the van side. The evaporator/ regulator is fitted in the engine compartment and the venturi is purpose-made to fit between the air filter and carburetter. In Transit vehicles the venturi is in fact sandwiched between the float cover assembly and the lower part of the carburetter.

The pipe work involved is relatively simple; the gas-feed line from the tank to the regulator is a solid-drawn steel pipe (a statutory requirement) and it clipped at approximately 18 inch centres. Where it would otherwise be exposed to the elements it carries a substantial nylon sleeve.

Correct mixture

I was told by Mr Thornton that once the LPG system is correctly tuned there is rarely any further necessity to touch it. The correct combustion mixture is achieved in two stages, and it is checkec using a continuous exhaust gas analysis At engine idling speeds the tick-ovei mixture screw on the regulator i adjusted until a 0.5 1.0 per cent CC (Carbon Monoxide) reading i: achieved. The engine revs are thet increased to 2,000 rpm and the mail feed line screw is adjusted until the samt 0.5 1.0 per cent CO output is obtained As a final check the proportion of CO it the exhaust gas is measured using Drager tube — a CO indicator versior of breath-testing equipment. This fina test takes about one and a half minute! to complete.

To control the flow of gas to the engine the regulator uses twc diaphragms. But unfortunately the purity of the LPG available is not at high as Mr Thornton would like, and or rare occasions grit in the gas has causec the smaller idling diaphragm to stick However, the regulator is easily removed and the diaphragm cleaned Apart from this minor problem the unii has proved to be trouble free.

A further filter is incorporated in the feed-line between the tank and regulator; it has very fine mesh and to al intensive purposes it can be regarded at a solid piece of material. The only indication that the filter is becoming choked is engine fuel starvation — it it hopeless trying to look through the filter.

An oPerational advantage of LPG it the absence of the cold-start syndrome once the engine has fired. The vehick can be immediately driven as if it had a warm engine. However, Mr Thornton has experienced difficulty in training hit drivers to adopt the correct cold-star technique. The choke equivalent for the LPG engine is a small button which needs to be blipped quickly to allow a controlled amount of gas into the engine before cranking.

His drivers hold the button down fox too long and so flood the engine. For the best results the throttle is held half open during cranking.

Fuel cost

In January this year Mr Thorntor completed a fuel consumption analysit between petrol and LPG fuel vehicles Basing the costs of what he pays foi LPG and petrol, the gas vehiclet represent a saving of £69,366 a year. F01 his analysis he used 450 vehicles which are mostly used on stop/ start operation.

Unless the tax levied on LPG it drastically increased from its preseni 11.25 per cent Mr Thornton seems to be on a winning wicket. As fuel costs have increased the price differential betweer LPG and petrol has widened, and if the trend is continued the savings to be achieved will obviously be proportion: ately greater. The present cost margin between the fuels is about 22p per gallon.

For fitting LPG equipment NEGAS get an allowance on vehicle taxation weight and when compared to licensing costs for similar non-converted petrol vehicles Mr Thornton saves f 1 1,353 a year.

Taking out those vehicles that would otherwise qualify for annual plating, but for the allowance on unladen weight given for fitting LPG equipment Mr Thornton saves a further £1,822 a year on test fees.

Apart from the use of LPG to reduce maintenance costs, Mr Thornton has developed his own service programme which keeps his Vehicle's downtime to between 2 and 3 per cent when other regions have recorded downtime figures of as much as 12 per cent.

Regular servicing of fleet vehicles is carried out at the NEGAS workshops during the night and the day shift is used to cover repair and other work. Vehicles based at local depots are brought in for service by their regular drivers while vehicles from outlying spots are picked up by a transporter.

Quality control

Before entering the workshops all the vehicles are checked by a quality control department who as part of their equipment use a rolling road and an inspection pit. Any faults found are duly noted and dealt with after the vehicle has undergone its normal service. Drivers defect reports are sent with the vehicle to the qbality control section who investigate, make the diagnosis and instigate any workshop action. After the repairs have been carried out the quality control department rechecks the vehicle to ensure that its condition is satisfactory. Following investigations into the downtime incurred for sending vehicles to outside contractors for rectifications of accident damage, Mr Thornton has altered the vehicles' insurance policies from fully comprehensive to third-party only, and he now carries out his own repairs. In this way he has made direct savings of £21,000 a year (excluding downtime) and maintains complete control of all his vehicles during the repair process.