IS THIS THE IDEAL EIGHT-WHEELER?

Page 50

Page 51

Page 52

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon, A.M.I.R.T.E.

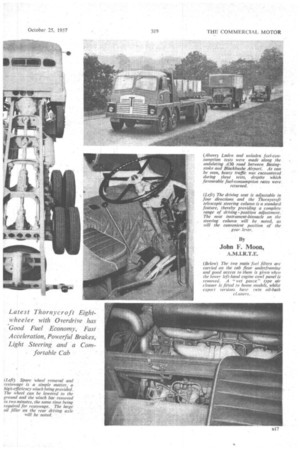

HAVING spent two days testing the new Thornycroft Trusty PK /QR6 maximum-load . eight-wheeler, I am inclined to think that this is perhaps the finest chassis of its type ever to have been built in this country. It offers good fuel economy, extremely safe braking, lively acceleration, more than adequate gradient performance and first-class driving conditions.

Reference to the fuel consumption, acceleration and braking figures recorded in the data panel serves to substantiate this statement, but without having driven the vehicle it would be impossible to sum up its true worth. Even in respect of suspension the chassis is outstanding, whether laden or unladen, and demonstrates that conventional semi-elliptic springs can give a ride approaching that of air springs.

Prototype Shown in 1955 The prototype of this chassis was first seen by the public at the 1955 Scottish Motor. Show, and the preproduction version was exhibited at the Commercial Motor Show at Earls Court last year. Over this period subtle modifications have been made, with the result that the chassis, Which is now in full production, has few of the faults to be normally found on the initial Production batch Of any new vehicle.

In terms of general layout it is conventional and many !eatures from the earlier PF eight-wheeled chassis have been retained. Four-spring balance-beam rear-bogie suspension has been adopted, however, and the road performance has been immeasurably improved by the use of the new QR6 9.83-litre oil engine and a new fivespeed constant-mesh gearbox which can, as on the test vehicle. be provided with a sixth overdrive ratio.

Because of the relatively low axle ratio of 7.25 to this overdrive can be used as a normal top gear at speeds down to 14 m.p.h., and engine torque is such that when running normally most of the time is spent in overdrive.. It should be a standard fitting.

Among. other unusual features are eight-wheel brakes and a Clayton Dewandre hydraulic steering servo as n16

standard equipment. These two characteristics combine to make the Trudy easily maneeuvrable (the turning circle is 73 ft.) and extremely safe under all conditions, the maximum retardation and anti-fade properties being first-class.

Three versions of the Trusty eight-wheeled chassis are offered: a double-axle-drive model with fourspring rear-bogie suspension, as tested: a double-axledrive chassis with fully articulated two-spring bogie suspension, mainly for use over rough surfaces; and a single-axle-drive chassis with four-spring suspension. This third, unlike the other two versions, is not recommended for service with a drawbar trailer.

All these chassis have a similar general layout, including *-in.-thick, frame members, the longitudinals having a maximum depth of 11 in., with 3+-in. flanges. A new style of cab has been developed and this is to be standard on all the new Trusty maximum-load chassis. It is an all-steel assembly with a distinctive new radiator grille, and, being full-width, there is plenty of room for driver and mate. Plastics are used for the cab lining panels, and fittings include two ashtrays and an interior light. The simple but adequate instrument panel is clamped to the steering column.

Although this chassis has several features which are not included on other eight-wheelers, such as eight-wheel brakes, power steering and spare-wheel winch, it is light. Complete with a 24-ft. platform body, its kerb weight is only 7 tons 141 cwt.

The body itself is interesting, in that it is, perhaps, the first attempt by a vehicle manufacturer to build S body to match the braking power. The headboard is heavily reinforced by panelled bracing which tends to improve the appearance of the complete vehicle, besides protecting the driver, whilst not reducing the payload. space.

AN Tyres Equally Loaded

A test load totalling 16 tons 51 cwt. had been added to bring the gross weight, less driver, passenger and test equipment, to 24 tons exactly, the distribution being such that each of the 12 tyres was equally loaded.

A calibrated fuel-test tank had been provided and, using this, a 13-mile fuel-test run was made along the A30 road between the Basingstoke By-pass and Blackbushe airport. This is a severely undulating, busy section of road with only two lanes, and including two hills which demanded the use of third gear and brought the speed down to.15 m.p.h. Nevertheless, the distance was

completed at an average speed of 24.8 m.p.h., four-fifths of the time having been spent in overdrive ratio, and the fuel-consumption rate wasP 8.2 m.p.g.

Following the braking and acceleration tests, a second consumption run was made on the way back to Basingstoke. The westward direction was slightly more favourable and produced a fuel-consumption figure of 9.4 m.p.g. at 27.7 m.p.h. average speed, all but 21 min. being spent in overdrive. This run, which is more representative of trunk routes throughout the majority of the country, gave a time-load-mileage factor of 6,250 -an exceptional figure.

First-class Braking Figures Braking and acceleration tests wez e conducted along a quiet level stretch of road at the back of Blackbushe airport. The braking figures produced show the advantage of 'having eight-wheel brakes (I believe they should be compulsory on all eight-wheelers) and the advisability of having a well.-reinforced headboard. The full line pressure of 105 p.s.i. was used for these tests. Although there was no definite delay in the system, the pressure build-up was noticeable and accounted for a difference of approximately 10 per cent. effective between the maximum deceleration recorded on the Tapley meter and the average deceleration shown by the stopping distances.

Nevertheless, the brakes are outstanding and, although operated by a treadle-type pedal with only limited movement, they are responsive and fully proportional to pedal travel. They are thus safe to use when unladen on wet or slippery roads. For most normal braking, in fact, it is necessary to depress the pedal through only a few degrees, and maximum braking is given by 50 lb. pressure on the pedal.

For the standing-start acceleration tests second, third, fourth and fifth gears were used, and for the direct-drive 10-30 m.p.h. runs fifth gear was employed. The good 0-30 m.p.h. figures recorded prove, among other thinks, that extremely quick gear-changes can be made, principally because the engine speed dies down rapidly when the throttle pedal is relpsed. Both sets of figures reflect the good torque characteristics of the engine (the torque curve varies by only 10 lb.-ft. between 900 r.p.m. and 1,500 r.p.m.) and the wisely chosen spread of gear ratios, helped by a short gear-lever travel and light clutch.

Farleigh Hill, the 1.4-mile-long incline which is an invariable feature of Thornycroft road tests, was the scene of the hill-climb and brake-fade tests. It has an average gradient of I in 27 and the steepest section is I in 8.4. Tests were made in an ambient temperature of 59'F.

Several climbs were made, the fastest being completed in a total time of 5 minutes 51 seconds—an average speed of 14.4 m.p.h., which is very fast for a 24-tonner. During this ascent just over two minutes were spent in second gear, the minimum road speed being 6 m.p.h.

A stop-start test was conducted on the steepest section during a subsequent climb, and two pulls on the Neate's triple-pull hand brake were sufficient to hold the vehicle in perfect safety. Bottom gear, was selecte& for the re-start and only quarter throttle was required for the get away, this being extremely smooth.

At the completion of each of these climbs . the temperature of the water in the radiator header tank was taken and the highest recorded was142° F. The engine thermostat had not opened. Engine cooling was more than adequate but did not impair efficiency.

Three descents were made to test the brakes, each of these lasting approximately four minutes, of which 11 minutes were spent in neutral. For the rest of the time direct drive was engaged and full throttle applied, the brakes in each instance, being used to restrict the speed to 20 m.p.h.

At the end of the first descent a "crash " stop from 20 m.p.h. produced a Tapley meter reading of 66 per cent. The two subsequent descents each yielded readings of 50 per cent., there having been less than a third reduction in efficiency compared with the figures taken with cold drums.

Drum Area Adequate•

Although woven facings were used, the large drum area (2.073 sq. in.) was adequate to keep the brakes cool under such conditions. It would require ruthless driving to produce under service conditions the amount of fade recorded during these tests.

On the second day, the BasingstokerBlackbusheBasingstoke fuel-consumption run was repeated with the vehicle unladen, and during both sections of the test, overdrive gear was used continuously., The resulting average figure of 14.6 m.p.g., which was obtained at an overall average speed of 27.3 m.p.h., again serves lo highlight the fuel economy of this design. An operator running laden in one direction and returning empty could expect to return nearly 12 m.p.g. as an overall figure.

The Trusty eight-wheeler approaches the driver's ideal. All-round visibility is excellent, aided by twin driving mirrors and a deep windscreen which gives ground-level vision to within 11 ft. of the front bumper. The seat is adjustable vertically and backwards and forwards, and the Thornycroft telescopic steering column is, of course, a standard fitting, thereby providing wide variations in 'driving position.

The power steering worked faultlessly, with no delay in application of the power, and sufficient " feel " to prevent the driver gaining. the impression of being divorced from the road. Castor action is. retained, although this is naturally reduced when running unladen.

A relief valve in the system ensures that the wheels cannot be turned when the vehicle is stationary, thus reducing the possibility of excessive tyre wear occurring when manceuvring in close confines.

Engine noise in the cab was commendably quiet, partly because of the quilted bonnet cover, which is' available as an optional extra. Other extras fitted included prominent flashing indicators on the cab sides and at the rear of the chassis, and a most effective freshair heating and demisting set.

Small points of criticism are that at idling speed and when pulling hard slight engine vibrations are transmitted to the cab floor, which is mounted separately from the main cab assembly. I was surprised also to find that powerful dual-note horns were not fitted to a vehicle of this size and with such speed potentialities.

Brake Adjustment Maintenance tests showed that generally the chassis was easy to service and in certain respects, particularly with regard to brake adjustment,. was much above normal.

For instance, all eight brakes can.be adjusted in under 12 minutes, slack in the four rear brakes being taken up by a single turn-buclsle in the hand-brake linkage. It is necessary to jack up only one wheel to ensure equal adjustment throughout the bogie. This operation takes only 41 minutes, including jacking up and lowering the wheel.

The front brakes are adjusted by means of a nut on the end of each cam-operating lever, and I attended to the brakes of both axles in seven minutes.

All the level checks are simple. The oil level in each of the driving axles can be verified in 11 minutes. A large swivelling flap on each axle casing simplifies topping-up. The gearbox oil level, which can be checked from beneath the vehicle, was ascertained in 45 seconds.

Access to the engine dipstick is given by lifting the left side of the bonnet cover and raising the upper hinged portion of the engine cowl; the level was checked in 11 minutes. There is only an external filler cap for the radiator (unlike some of the lighter Thornycrofts, which have interior and exterior fillers) and the water level can be visually checked in 45 seconds.

The four 6v. batteries are carried on the off-side frame member immediately behind the second axle, and the metal cover over the batteries is secured by two wing nuts. Inspection of the electrolyte levels is therefore simple, taking only four minutes, but I did find the rubber cell plugs awkward to remove. This is particularly the case if grease has got on to them.

There are two main fuel filters, which are reached through the left bonnet side, and theelements in each of these can be removed in Li minutes, though, as usual, replacement of the filter bowls is a little more difficult and takes 3-1 minutes in each case.

For many years a feature of all Thornycroft heavy chassis has been the spare-wheel winch, which is operated from the rear. It takes only 2 minutes to lower the wheel to the ground without any effort, and, once on the ground, the carrying bar can be lifted dear of the wheel without undoing nuts