Oil-engined Tractors for Buses

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

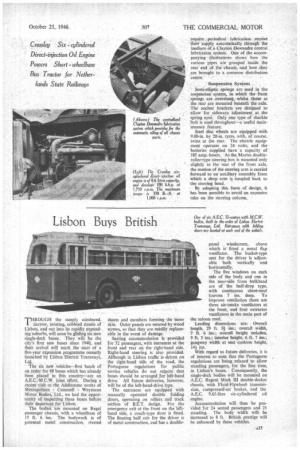

A S reported in "The Commercial Motor" last week, Crossley Motors, Ltd., Manchester, has started to supply to the Netherlands State Railways a large number of tractor chassis specially designed to draw a trailer-type bus with accommodation for 52 seated and 28 standing passengers. The company also has orders for single-deck bus chassis.

Powered by the Crossley sixcylindered direct-injection oil engine, the tractor chassis should go a long way towards advancing the prestige of British motor engineering interests abroad. The bore of the cylinders of this unit is 41 ins, and the stroke 5i ins., so that the capacity is 8,598 c.c. or 8.6 litres. This engine develops a maximum b.h.p. of 100 at 1,750 r.p.m. and has a maximum torque of 378 lb.-ft. at 1,000 r.p.m.

Engine Features Some of the chief features of the engine are that it has renewable drytype cylinder liners, a seven-bearing crankshaft fitted with a vibration damper, and enclosed overhead valves, with dual springs, operated by short push-rods, A twin gear-type oil pump is used, in which one set of gears is responsible for delivering oil to the main and bigend bearings, and the other supplies lubricant to the auxiliaries. A feature of the oil-circulating system is that there is an electric " tell-tale " indicator incorporated in the instrument panel.

The drive to the auxiliaries is by a triple-roller chain, the correct tensioning of which is automatically arranged. The connecting rods have shell-type big-ends, the bearing caps being held in position by four high-tensile-steel bolts per cap. Silentbloc bushes are used to provide a resilient form of engine mounting.

. A clutch of the single-plate type, incorporating a clutch stop, lakes the drive to a four-speed constant-mesh gearbox, the basic ratios of which are, first 4.86, second 3, third 1.81 and top, 1 to 1, with a reverse ratio of 6.99 to 1. As the wheelbase is but 11 ft., it is possible to use a one-Piece propeller shaft, and. this is fitted with Hardy A34 Spicer needle-roller-bearing universal joints.

The casing of the underslung-worm rear axle is machined from a one-piece alloy-steel drop forging. The rear-axle ratio is 5.75 to 1.

Brake Design The foot brake is assisted by vacuum servo, there being one main servo cylinder for the rear wheels, and two auxiliary cylinders for the front wheels. The auxiliary, cylinders are mounted directly on the axle beam adjacent to each front wheel.

In the unlikely event of the servo mechanism failing, this would not affect the foot-pressure-operation of the brakes.. As is the usual practice, the hand brake operates only on the rear

wheels. There are • two• interesting features worthy' of mention in connection with the braking, one being that the brake drums are removable without disturbing the wheel hubs, and, secondly, the brake facings overlap the drums, to facilitate removal.

All the points on the chassis which

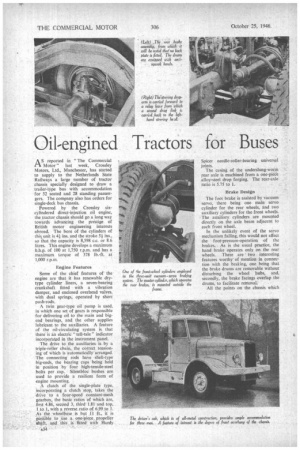

require periodical lubrication receive their supply automatically through the medium of a Clayton Dewandre central lubrication system. One of the accompanying illustrations shows how the various pipes are grouped inside the rear end of the chassis, and how they are brought to a common distribution centre.

Suspension System Semi-elliptic springs are used in the suspension system, in which the front springs are overslung, whilst those at the rear are mounted beneath the axle. The anchor brackets are designed to allow for sideways adjustment at the spring eye. Only one type of shackle bolt is used throughout—a useful maintenance feature.

Steel disc wheels are equipped with 9.00-in. by 20-in. tyres, with, of course. twins at the rear. The electric equiprnent operates on 24 volts, and the batteries supplied have a capacity of 185 amp.-hours. As the Marles doubleroller-type steering box is mounted only slightly to the rear of the front axle, the motion of the steering arm is carried forward to an auxiliary assembly from whielt a drop arm is coupled back to the steering bead.

By adopting this form of design, it has been possible to avoid an excessive rake on the steering column,