Repairs to Steam-Wagon Boilers.

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Contributed by an Engineer-in-Charge.

Ile importance of keeping steam-wagon boilers in firstclass condition cannot be over-estimated; and yet they come in for more abuse, in many cases, than any other pre Many men have the idea that, as long as they keep putting water into the boiler, keep up a good lire, and the boiler keeps making steam, everythingis right, and things are allowed to go on in this manner until a serious accident happens. Others look on any job connected with a boiler as being dirty and uninteresting work. It is, probably, awkward to get at, and work on it is classed as a job to be left religiously alone : it is, therefore, left undone until it is practically impossible to run any longer. Whilst admitting that many jobs are dirty and awkward, and that a fire-box is not one of the hest places to work in, yet; by a

careful study of steam boilers, it will be found that they are very interesting, and will more than repay one for the unpleasant experiences in watching their peculiarities.

The most common defects in a boiler are as follows • Seams, tubes, stays, and rivets become leaky., and the moisture from them causes " wasting " very rapidly; in fact, the plates are eaten away until the boiler becomes insufii• ciently strong to stand the working perssure. The best way to remedy this is to strip the boiler of its laggingand to get up steam. I usually, however, have the lagging off directly a wagon conies in from a journey, as any defective scams or rivets show up more then, and I mark any part where it is " weeping," although one can easily see where a seam or rivet has been leaking by the deposit left on the plates. Leakages in the fire-box can best be seen at night when the fire is low and nice and clean ; make a note of these so that they can be remedied when the boiler has cooled down ciently to enable one to get into the fire-box. A caulking teol (Fig. t), which is like a short chisel ground off on one side, vihl be required. It should not be too keen, and should be slightly rounded to prevent the corners digging in. With a hand hammer and this tool the edge of the plate (Fig. 2) should be caulked. Light blows should be given, and the caulking tool should be moved along about half its width after each blow; the joint should be gone over two or three times. The heads of the rivets should be caulked round in the same way, after they have been sounded in order to see that they are quite tight; all the caulking in the world will not stop them if they are stack. The only remedy, in this latter case, is to cut the rn et out arid put in another. It is not advisable to caulk any more than is necessary to make the defective part steam light; very often more harm than good is done by continuing after this has been attained. The next examination necessary is that of the fire-box and smoke-box, and this is where, most often, trouble is likely to occur. Take off the ash-pan and take out all the fire-bars. Give the fire-box a thorough scraping, to remove all the scale and soot, and expose the comparatively clean plates. These must be examined very closely for cracks, blisters, or any bulging; the screwed stays must be scrutinised for leakages and sounded with a hammer to make sure that they are not loose or cracked. Next, the rube plate must be looked at, as there may be a crack from one tube to another, and the fusible plum should be taken out, as it is always advisable, if it has been in for any length of time, to ascertain the state of the soft metal inserted in its centre. In the event of leaky tubes being found, a tube expander will be required which fits that particular size of tube. It is preferable to use one with three rollers. Insert this in the tube to be expanded—with a moderate amount of pressure, so that you can turn it evenly and gently with the tommy-bar provided for the purpose, and rotate it in the inside of the tube several times, forcing the expanding man. dril in a little further each time. It frequently happens that tubes, after being expanded, will still leak, and, in that case, you will require a ferrule, i.e., a piece of tube about 1.1in. long, which is a good driving fit in the tube itself. This must be driven into the end of the tube in such a way that the inside end is brought just beyond the tube plate : it should then he expanded in the same way. In most boilers the ends of the tubes have a slightly larger diameter than the rest of the tube, to facilitate " drawing." In the event of having a split tube, it can best be drawn out by means of a long stud threaded for about fin, at one end and having a nut on the other end (Fig. 3). A thick washer, having two diameters, should be turned : the smaller diameter should fit the inside of the tube freely, whilst the face of the larger one should abut against the end of the tube (A, Fig3)The rod should then be passed through the tube from the smoke-box end, the washer put on, and the nut screwed up. Two pieces of hard wood (B, Fig. 3) and a plate (C, Fig. 3), with a hole in the .centre, should be obtained. The plate, passed over the other end of the rod, should rest upon the hard wood packing, and the nut, upon being screwed up on this end will draw the tube : the same tackle can be used for putting the new tube in if necessary. In the event of finding a cracked plate, when the extent of the crack has been carefully ascertained, a small hole should be drilled at each end to prevent it from going any further. These holes must them be tapped and a piece of steel screwed in tightly and cut off flush with the plate. A piece of mild steel plate, about the same thickness as the original plate and large enough to cover the crack properly, will next be required. Holes, drilled and countersunk to receive the screws, which should have countersunk heads and squares for screwing them in with (Fig. 4), should have been made in this plate. Round the crack, the position the plate is to occupy, should be marked on', the plate should be laid in this position and strutted up from the opposite side of the fire-box, in order to force it up tight while the holes arc marked off on the side of the fire-box for drilling. After centre-punchin.g these holes, a ratchet brace should be rigged up, always remembering that, unless these holes arc drilled exactly to the marks, endless trouble will be experienced in getting the bolts to go in fair; as, if it is necessary to file the holes in the plate to bring them fair, the countersink in the plate will be out and will make it impossible for the

head of the bolt to bed down properly. In tapping the holes, care should be taken that a good full thread is obtained, and that the tap goes in quite square; any tendency to go in at an angle must be corrected with the wrench, by putting more pressure on the side the tap requires to go than on the other. To get the size of the drill, it should be ground down until it will pass through a nut which fits the bolt; the drill should pass through treely, as it will cut a hole slightly larger than its actual diameter. Previous to drilling the plate, it should be bedded down to the fire-box, using a file or scraper if necessary, otherwise a thick joint will have to be used, with an increased risk of the joint being blawn out. The patch should now be put in position, and all the bolts tried in their places; then the patch and its position on the fire-box should be painted with boiled linseed oil, the patch covered with red lead paste, put in position with the bolts, which should then be screwed up evenly and regularly. A blistered plate is caused during the operation of rolling the layers of metal; the blister must be chipped off, and a patch put on over the part that has been chipped away. The screwed stays in the sides of loco type boilers are likely to become loose or to fracture, owing to strains being set up by the difference of the expansion of the fire-box and of the shell plates. These must be carefully sounded with a hammer to make sure that they are in order, for, if they are broken or corroded, the pressure on the unsupported part of the fire-box, or shell, may cause bulging. If the stay is broken, it will have to be taken out and replaced by a new one, either by chipping the head of the stay square to take a wrench, or, failing that,

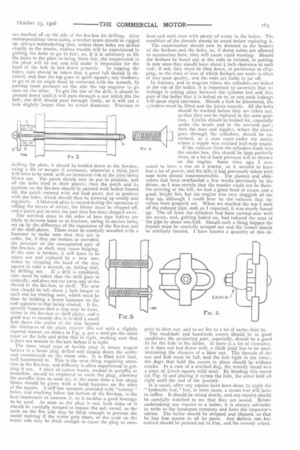

by drilling out. If a drill is employed, care must be taken that the drill goes in centrally, and does not cut away any of the thread in the fire-box, or shell. The new stay should be left about inch longer at each end for riveting over, which must be done by holding a heavy hammer an the end opposite to that being riveted. It frequently happens that a stay may be loose, either in the fire-box or shell plates, and a good way to remedy this is to drill a small hole down the centre of the stay beyond the thickness of the plate, reamer this out with a slightly tapered reamer, as shown in Fig. 5, get a steel pin the same taper as the hole and drive this in tight, making sure that it does not bottom in the hole before it is tight. The most usual type of fusible plug in steam wagon boilers is a brass plug drilled and tapped down the centre and countersunk on the water side. It is filled with lead, well hammered in. This is the next thing requiring attention in the fire-box, and difficulty is often experienced in getting it out. A piece of-cotton waste, soaked in paraffin or benzoline, should be employed to swab the plug, allowing the paraffin time to soak in; at the same time a few sharp blows should be given with a hand hammer on the sides of the square. A stiff box spanner, provided with "tommy " holes, and reaching below the bottom of the fire-box, is the best implement to unscrew it, as it emtbles a good leverage to be used. As soon as the plug is out, both sides of it should be carefully scraped to expose the soft metal, as the scale on the fire side may be thick enough to prevent the metal melting if the water gets short, or the scale on the water side may be thick enough to cause the plug to over

Fic.5

heat and melt even with plenty of water in the boiler. The condition of the threads should be noted before replacing it.

The examination should now be directed to the bearers of the limbers and the bolts, as, if damp ashes are allowed to accumulate here, they will cause rapid wasting. Should the firebars be burnt out at the ends or twisted, in putting in new ones they should have about inch clearance at each end : if not, they roust be filed down, in preference to chipping, as the class of iron of which firebars are made is often of very poor quality, and the ends are liable to jar off. In tractors, and in wagons where the cylinders are bolted at the top of the boiler, it is important to ascertain that no leakage is taking place between the cylinder bed and that part of the boiler that it is bolted on to, as any such leakage will cause rapid corrosion. Should a leak be discovered, the cylinders must be lifted and the joints remade. All the bolts should he marked before they are taken out, so that they can be replaced in the same position. Cracks should be looked for, especially under the heads and in the screwed part ; then the nuts and nipples, where the steam goes through the cylinders, should be examined, as a case came under my notice where a nipple was cracked half-way round.

If the exhaust from the cylinders leads into the smoke box, this should be kept perfectly clean, or a lot of back pressure will be thrown on the engine. Sonic time ago I was asked to have a run on a tractor, as it seemed to have lost a lot of power, and the hills it had previously taken with ease were almost insurmountable. The pistons and slidevalves had been overhauled a few weeks previously by the driver, so I was certain that the trouble could not be there. On arriving at the hill, we had a good head of steam and a good, bright fire, but the engine was very sluggish all the way up, although I could hear by the exhaust that the valves were properly set. When we reached the top I took off the exhaust pipe, and, as I expected, it was nearly furred up. The oil from the cylinders had been carried over with the steam, and, getting baked on, had reduced the area of the pipe by about one-half. Should such a thing happen the deposit must be carefully scraped out and the funnel should be similarly treated. I have known a quantity of this de posit to blow out, and to set fire to a lot of sacks c ose by. The mud-hole and hand-hole covers should be in good condition ; the projecting part, especially, should be a good fit for the hole in the boiler. If there is a lot of clearance, or it does not bed down well, a thick joint has to be used, increasing the chances of a blow out. The threads of the nut and bolt must be full, and the bolt tight in the cover ; the dogs that hold the covers in place should be without cracks. In a case of a cracked dog, the remedy found was a piece of i-inch square mild steel. By bending this round (as Fig. 6) and placing it across the hole, the cover held all right until the end of the journey.

It is usual, after any repairs have been done, to apply the " hydraulic test," but, in most cases, a steam test will have to suffice. It should be raised slowly, and any repairs should be carefully watched to see that they are sound. Before undertaking any repairs to a boiler, it is always advisable to write to the insurance company and have the inspector's advice. The boiler should he stripped and cleaned, so that he has free access to all its parts. Any defects one has noticed should be pointed out to him, and the remedy asked.