SIX WHEELS •F

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

rEAm VEHICLES.

Exclusive Particulars of Most Interesti Type Built by Ri

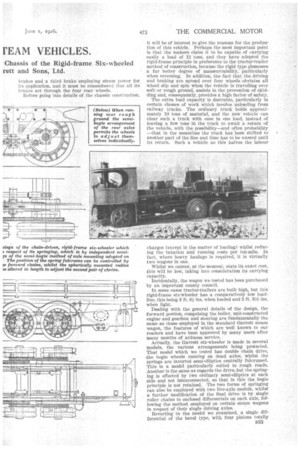

Chassis of the Rigid-frame Six-wheeled rett and Sons, Ltd. SOME MONTIIS ago we were afforded an opportunity for examining the drawings of a new type of steam rigid-frame six-wheeler which was being built by that old-established company, Richard Garrett and Sons, Ltd., LQ147011 Works, Leiston, Suffolk. We were so favourably impressed with the methods adopted that we expressed a wish to examine and try out the vehicle so soon as possible after it had been placed on the road, and a few days ago we journeyed to Leiston for this purpose, being received by the managing director, Mr. R. True, Colonel Garrett and Mr. M. G. Plane, the chief designer.

As will be seen from our illustrations, the vehicle was still under test, with a temporary body and carrying a 14-ton load, the total weight being just under 24 tons. The chassis is actually designed for useful loads of 12 tons, in which case the axle weights total just under 22 tons ; the weight on each rear axle does not exceed 8 tons. However, overloaded BLS it was, the new machine had been put through rigorous trials without any weaknesses developing.

For some time we watched it making repeated trips over an unmade road full of pot-holes up to 18 ins, deep, and it was an eye-opener to observe the manner in which tile vehicle, instead of bouncing in and out of these holes, appeared to pass over them, this being due to the careful design of the inverse, semi-elliptic springing, in which each spring is separately fulcrumed and rests on slipper blocks at its ends, whilst the two driving axles are held by radius and torque members spherically mounted to give freedom of movement in the desired planes.

To ascertain if the comfort of riding was really as good as it appeared, we made a circuit of the course on the vehicle, and we found that even when passing over the worst pot-holes at a speed of from 12 m.p.h. to 15 m.p.h., no disagreeable shock was experienced, the vehicle merely receiving a wave-like motion. It must not be thought that the driving wheels jumped the holes. They followed every unevenness of the ground, and, owing to their freedom of motion, could rise and fall to a large extent without causing other than a slight lift or fall of the chassis frame.

Next we had a run of some miles on the road, and here the absence of shock was remarkable; in addition, the vehicle could be manceuvred round sharp corners with the utmost ease, and although still carrying its useful load of 14 tons, with an addition, in this instance, of seven persons, it achieved 23 m.p.h. on the level and 15 m.p.h. on a fairly steep incline, and this despite the fact that ordinary steam coal instead of smokeless fuel was employed.

The turning circle has a radius of 26 ft., and owing to the distribution of the load over the six wheels the vehicle can run over rough and comparatively soft ground which would quickly stall a Wagon driving on two wheels only. On one occasion, in addition to its load of 14 tons, it towed a vehicle having a total weight of 10 tons from Aldeburgh to Leiston, running in top B32 gear all the way, with the exception of the 1-in-15 hill at the start.

Excellent braking power is one of the characteristics of the new vehicle. It has hand and foot-operated brakes and a third brake employing steam power for its application, and it must be remembered that all its brakes act through the four rear wheels.

Before going into details of the chassis construction, it will be of interest to give the reasons for the production of this vehicle. Perhaps the most important point is that the makers claim it to be capable of carrying easily a load of 12 tons, and they have adopted the rigid-frame principle in preference to the tractor-trailer method of construction, because the rigid type Possesses a far better degree of manoeuvrability, particularly when reversing. In addition, the fact that the driving and braking are spread over four wheels obviates all wheel slip and spin when the vehicle is travelling over soft or rough ground, assists in the prevention of skidding and, consequently, provides a high factor of safety.

The extra load capacity is desirable, particularly in certain classes of work which involve unloading from railway trucks. The ordinary truck holds approximately 10 tons of material, and the new vehicle can clear such a truck with ease in one load, instead of leaving a few tons in the truck to await a return of the vehicle, with the possibility—and often probability. —that in the meantime the truck has been shifted to another part of the line and time has to be wasted until its return. Such a vehicle as this halves the labour charges (except in the matter of loading) whilst reducing the taxation and running costs per ton-mile. In fact, where heavy haulage is required, it is virtually two wagons in one.

Whilst we cannot, at the moment, state its exact cost, this will be low, taking into consideration its carrying capacity.

Incidentally, the wagon we tested has been purchased by an important county council.

In some cases tractor-trailers are built high, but this rigid-frame six-wheeler has a comparatively low load' line, this being 3 ft. Si ins, when loaded and 3 ft. 10, when light. Dealing with the general details of the design, the forward portion, comprising the boiler, unit-constructed engine and gearbox and steering are fundamentally the same as those employed in the standard Garrett steam wagon, the features of which are well known to our readers and have been approved by many users after many months of arduous service.

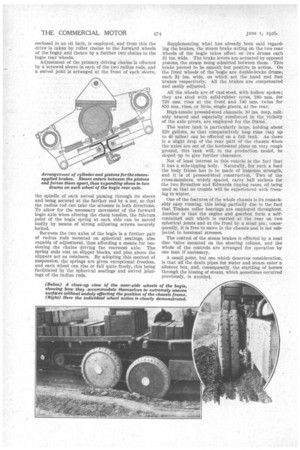

Actually, the Garrett six-wheeler is made in several models, the various arrangements being protected. That model which we tested has double chain drive, the bogie wheels running on dead axles, whilst the springs are inverted semi-elliptics centrally fulcrumed. This is a model particularly suited to rough roads. Another is the same as regards the drive, .but the springing is effected by two ordinary semi-elliptics at each side and not interconnected, so that in thiS the bogie principle is not retained. The two forms of springing can also be employed with two live-axle models, whilst a further modification of the final drive is by single roller chains to enclosed differentials on each axle, following the method employed on certain steam wagons in respect of their single driving axles. Reverting to the model we examined, a single differential of the bevel type, with four pinions totally 1333 enclosed in an oil bath, is employed, and from this the drive-is taken by roller chains to the forward wheels of the bogey and thence by a further two chains to the bogie rear wheels.

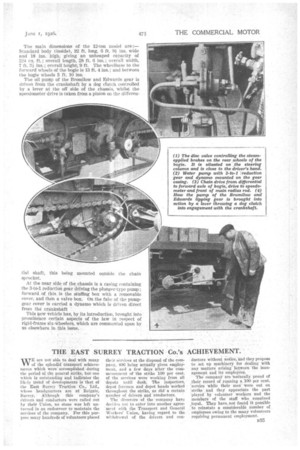

Adjustment of the primary driving chains is effected by a screwed sleeve in each of the two radius rods, and a swivel joint is arranged at the front of each sleeve, the spindle of each swivel passing through its sleeve and being secured at the farther end by a nut, so that the radius rod can take the stresses in both directions. To allow for the necessary movement of the forward bogie axle when altering the chain tension, the fulcrum point of the bogie spring at each side can be moved bodily by means of strong adjusting screws securely locked.

Between the two axles of the bogie is a further pair of radius rods mounted on spherical seatings, also capable of adjustment, thus affording a means for tensioning the chains driving the rearmost axle. The spring ends rest on slipper blocks, and pins above the slippers act as retainers. By adopting this method of suspension, the springs are given exceptional freedom, and each wheel can rise or fall quite freely, this being facilitated by the spherical seatings and swivel jointings of the radius rods. Supplementing what has already been said regarding the brakes, the steam brake acting on the two rear wheels of the bogie takes effect on two drums each 3i ins. wide. The brake levers are actuated by opposed pistons, the steam being admitted between them. This brake proved to be smooth but positive in action. On the front wheels of the bogie are double-brake drums, each 31 ins, wide, on which act the hand and foot brakes respectively. All the brakes are compensated and easily adjusted.

All the wheels are of cast-steel, with hollow spokes; they are shod with solid-rubber tyres, 180 ram. for 720 mm. rims at the front and 140 mm. twins for 850 mm. rims, or 10-in, single giants, at the rear.

High-tensile pressed-steel channels, 10 ins, deep, suitably braced and especially reinforced in the vicinity of the axle pivots, are employed for the frame.

The water tank is particularly large, holding about 320 gallons, so that comparatively long runs (say up to 40 miles) can be effected on a full tank. As there is a slight drop of the rear part of the chassis *hen the axles are out of the horizontal plane on very rough ground, this tank will, in the production model, be sloped up to give further clearance.

Not of least interest in this vehicle is the fact that it has a side-tipping body. Naturally, for such a load the body frame has to be made of immense strength, and it is of pressed-steel construction. Two of the cross-members, widely spaced, carry ball sockets for the two Bromilow and Edwards tipping rams, oil being used so that no trouble will be experienced with freezing in winter.

One of the features of the whole chassis is its remarkably easy running, this being partially due to the fact that Timken roller bearings are employed throughout. Another is that the engine and gearbox form a selfcontained unit which is carried at the rear on two spherical joints and at the front by a stout pin; consequently, it is free to move in the chassis-and is not subjected to torsional stresses.

The control of the steam brakes is effected by a neat disc valve mounted on the steering column, and the whole of the controls are arranged for operation by one man if necessary.

A small point, but one which deserves consideration, is that all the drain pipes for water and steam enter a silencer box, and, consequently, the startling of horses through the hissing of steam, which sometimes occurred previously, is avoided.

The main dimensions of the 12-ton model are:— Standard body (inside), 22 ft. long, 6 ft. 94 ins, wide and 18 ins, high, giving an unheaped capacity of 224 cu. ft.; overall length, 28 ft. 6 ins. ; overall width, 7 ft, 3.1 ins. ; overall height, 9 ft. The wheelbase to the forward wheels of the bogie is 13 ft. 4 ins.; and between the bogie wheels 3 ft. 10 ins.

The oil pump of the Bromilow and Edwards gear is driven from the crankshaft by a dog clutch controlled by a lever at the off side of the chassis, whilst the speedometer drive is taken from a pinion on the differen fiat shaft, this being mounted outside the chain sprocket.

At the near side of the chassis is a casing containing the 3-to-1„ reduction gear driving the plunger-type pump ; forward of this is the stuffing box with a removable cover, and then a valve box. On the fate of the pumpgear cover is carried a •dynamo which is driven direct from the crankshaft This new vehicle has, by its introduction, brought into prominence certain aspects of the law in respect of rigid-frame six-wheelers, Which are commented upon by us elsewhere in. this issue.