FITTINGS AND TOOLS FOR THE WORKSHOP.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Ideas Put Forward by our Driver and Mechanic Readers.

Tr HE task of filing platinum con tacts belonging to magnetos or distributors in such a manner that the faces are left perfectly flat is not easy. " W.H.S.," of Middlesbrough, suggests the use of a jig for this wort.

This tool is made in two parts, one being the head and the other the sp-nclle. The head is roughly box-like in shape, the top being a separate piece fixed by means of two small screws. The inner surfaces of the head are flat and care is taken to ensure the top being absolutely at right angles to the sides. The spindle is a really good fit in the barrel of the head, being lapped into it so that no play is noticeable.

In action a small flat file is laid inside the head, the contact to be treated is screwed into the spindle end, which is tapped to receive , it; the spindle is then slipped into the head so that the contact rests on the file, and by twisting the spindle the face of the contact revolves on the file and is trued. In cases where the platinum surface is really bad the spindle may be put into the chuck of a drilling machine or band brace so as to obtain greater speed of revolution.

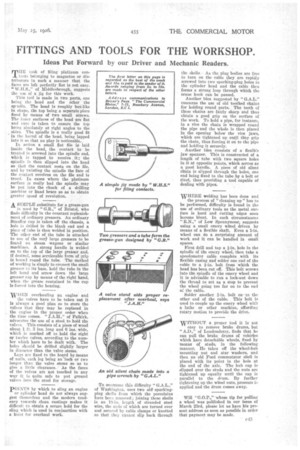

A SIMPLE substitute for a grease-gun is used by " G.R.," of Bristol, who finds diffichlty in the constant replenishment of ordinary greasers. An ordinary Stauffer cup is taken off the chassis, a hole is drilled in the blank end and a pieee of tube is then welded in position. The other end of the tube is attached to one of the ved large greasers to be found on steam -wagons or similar machines. A strong handle is welded on to the top of the large greaser and, if desired, some serviceable form of grip is bound round the tube. The method of working is simply to connect the small greaser to its base, hold the tube in the left hand and screw down the large greaser cap by means of the right hand, when the grease contained in the cup is forced into the bearing.

WHEN overhauling an engine and

the valves have to be taken out it is always a good plan so to store the valves that they may be replaced in the engine in the proper order when the time comes. "J.A.H.," of Falkirk, advocates the -use of a stool to hold the valves. This consists of a piece of wood about 1 ft. 3 ins. long and 8 ins, wide, which is marked off to hold the eight or twelve valves, according to the number which have to be dealt with. The holes should be drilled slightly larger in diameter than the valve stems.

Legs are fixed to the board by means of nails, each leg being an'inch or two longer than the valve stems so as to give a little clearance. As the faces of the valves are not touched in any way it is quite safe to put ground valves into the stool for storage.

pOINTS by which to sling an engine or cylinder head do not always suggest themselves and the modern tendency towards clean castings makes it difficult to obtain a secure hold for the sling which is used in conjunction with a hoist for overhaul work. To overcome this difficulty " G.A.L.," of Washington, uses two old sparkingplug shells from which the porcelains have been removed; joining these shells is an 18-in. length of stranded steel wire, the ends of which are turned over and secured by cable clamps or knotted so that they cannot slip back through

the shells. • As the plug bodies are free to turn on the cable they are rapidly screwed into two sparking-plug holes in the cylinder head and the cable then forms a strong loop through which the crane hook can be passed.

Another Idea suggested by " G.A.L." concerns the use of old toothed chains for holding round parts. The teeth of these chains are fairly sharp and thus obtain a good grip on the surface of the work. To hold a pipe, for instance, in a vice the chain is wrapped round the pipe and the whole is then placed in the opening below the vice jaws, which are tightened up until they grip the chain, thus forcing it on to the pipe and holding it securely.

Another idea consists of a flexiMe jaw spanner. This is constructed of a length of tube with two square holes in it at opposite points, which serves as a good handle. A piece of old silent chain is slipped through the holes, one end being-fixed to the tube by a bolt or rivet, thus providing a tool capable of dealing with pipes.

WHERE welding has been done and the process of "cleaning up" has to be performed, difficulty is found in the use of ordinary tools as the metal surface is hard and cutting edges soon become blunt. In such circumstances "R.N.," of Low Spennymoor, suggests using a small emery wheel driven by means of a flexible shaft. Even a 1-in. wheel can do a surprising amount of work and it can be handled in small spaces.

First drill and tap a fin. hole in the spindle of the emery wheel, then take a speedometer cable complete with its flexible casing and solder one end of the cable to a fin, bolt from which the head has been cut off. This bolt screws into the spindle of the emery wheel and it is advisable to run a lock-nut down the thread to act as a stop to prevent the wheel going too far on to the end oi the cable.

Solder another fin, bolt on. to the other end of the cable. This bolt is used to couple up the emery wheel with a lathe or other machine, affording rotary motion to provide the drive.

WITHOUT a proper tool it is not easy to remove brake drums, but "AD.," of Londonderry, finds that he can pull the brake drums of vehicles which have detachable wheels, fixed by means of studs, in the following manner. He takes off the wheel-hub mounting nut and star washers, and thou an old Ford commutator shell is placed with its point in the hale at the end of the axle. The hub cap is slipped over the studs and the nuts are tightened up equally until the cap is parallel to the drum. By further tightening up the wheel nuts, pressure is applied and the drum comes away.

Will "G.O.P.,""whose tip for pulling a wheel was published in our issue of March 23rd, please let us have his present address as soon as possible in order that payment may be made.