HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best out of a Vehicle, to Secure Reliability and to Avoid Trouble.

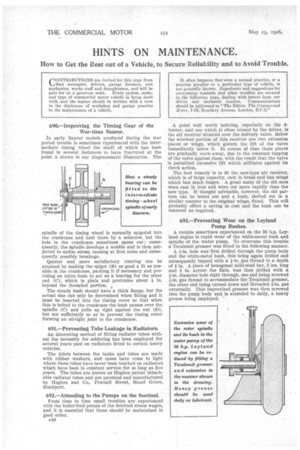

690.—Improving the Timing Gear of the War-time Saurer, In early Saurer models produced during the war period trouble is sometimes experienced with the intermediate timing wheel the shaft of which has been found in several instances to have fractured at the point A shown in our diagrammatic illustration. The

spindle of the timing wheel is normally spigoted into the crankcase and held there by a setscrew, but the hole in the crankcase sometimes opens out; consequently, the spindle develops a wobble and is then subjected to undue stress, causing at first noise and subsequently possibly breakage.

Quieter and more satisfactory running can be attained by making the spigot (B) as good a fit as possible in the crankcase, packing it if necessary and providing an extra bush to act as a bearing for the other end (C), which is plain and protrudes about in. beyond the threaded portion.

The steady bush should have a thick flange, but the actual size can only be determined when fitting and it must be inserted into the timing cover so that when this is bolted to the crankcase the bush passes over the spindle (C) and pulls up tight against the nut OM but not sufficiently so as to prevent the timing cover forming an oil-tight joint to the crankcase.

691.—Preventing Tube Leakage in Radiators.

An interesting method of fitting radiator tubes without the necessity for soldering has been employed for several years past on radiators fitted to certain heavy vehicles.

The joints between the tanks and tubes are made with rubber washers, and eases have come to light where these tubes have never been touched on radiators whirch have been in constant service for so long as five years. The tubes are known as Hughes patent detachable radiator tubes and are patented and manufactured by Hughes and Co., Pownall Street, Hazel Grove, Stockport.

692.—Attending to the Pumps on the Sentinel.

From time to time small troubles are experienced with the boiler-feed pumps of the Sentinel steam wagon, and it is essential that these should be maintained in good order.

c44 A point well worth noticing, especially on the 4tonner, and one which is often missed by the driver, is the air receiver situated over the delivery valve. Below the screwed portion of this receiver are two extension pieces or wings, which govern the lift of the valve Immediately below it. In course of time these pieces are gradually worn away, due to the constant tapping of the valve against them, with the result that the valve is permitted excessive lift which militates against its check action.

The best remedy is to fit the new-type air receiver, which is of large capacity, cast in brass and has wings which last much longer. A great many of the old ones were east in iron and wore out more rapidly than the new type. If thought advisable, however, the old pattern can be bored out and a bush, slotted out in a similar manner to the original wings, fitted. This will probably effect a saving in cost and the bush can be renewed as required.

693.—Preventing Wear on the Leyland Pump Bushes.

A trouble sometimes experienced on the 36 h.p. Leyland engine is rapid wear of the white-metal bush and spindle of the water pump. To overcome this trouble a Tecalemit greaser was fitted in the following manner.

A t-in. hole was first drilled through the pump body and the white-metal bush, this being again drilled and subsequently tapped with a 1-in, gas thread to a depth of ft in. A piece of hexagonal mild-steel bar, 3 ins, long and ft in. across the flats, was then drilled with a i-in. diameter hole right through, one end being screwed fin, gas thread to accommodate the Tecalemit greaser, the other end being turned down and threaded i-in. gas externally. This improvized greaser was then screwed into the pump body and is attended to daily, a heavy grease being employed.