• A SUCCESSFUL FRENCH GAS PRODUCER PLANT

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

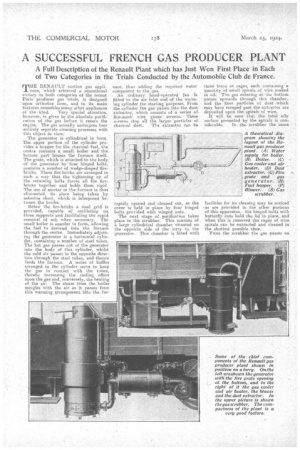

A Full Description of the Renault Plant which has Just Won First Place in Each of Two Categories in the Trials Conducted by the Automobile Club de France.

MHE RENAULT suction .gas appliance, which achieved .a sensational victory in both categories of the recent

Paris producer gas trials, is designed upon orthodox lines, and in its main features resembles many other appliances of the kind. Very special attention,

however, is given to the absolute purification of the .gas before it enters the engine. The gas actually undergoes four entirely separate cleaning processes with

this object in view,: —

. The geneziator is cylindrical in form. The upper portion of the cylinder provides a hopper for the charcoal fuel, thecentre contains. a small boiler and the, bottom part houses the furnace itself. The grate, which is attached to the body of the generator by 'four hinged bolts, contains a number of wedge-shaped firebricks. These fire-bricks are arranged in such a way that the tightening up of the retaining bolts forces all the firetricks together and holds them rigid. The use of mortar in the furnace is thus eliminated, its place being taken by. asbestos sheet, which is interposed between the bricks.

Below the fire-bricks a steel grid is provided, capable of oscillating on three supports and facilitating the rapid removal of ash when necessary. The small boiler is annular in form,.allowing the fuel to descend into the furnace through the centre. Immediately adjoining the generator is a horizontal cylinder, containing a number of steel tubes. The-hot gas passes nut of the generator into the body of this cylinder, whilst the cold air passes in the opposite direction through the steel tubes, and thence feeds the furnace. A series of baffles arranged. in the cylinder serve to keep the gas in contact with the tubes, thereby increasing the cooling effect upon the gas and, conversely, the heating of the air. The steam from the boiler mingles with the air as it passes from this warming .arrangement into the fur

nace, thus adding the required water component to the gas.

An ordinary hand-operated fan is fitted-to the air inlet end of the warming cylinder for starting 'purposes. From the cylinder the gag passes into the duSt extractor, which consists of a series of fine-mesh wire gauze screens. Th'ese screens stop all tlie larger particles of

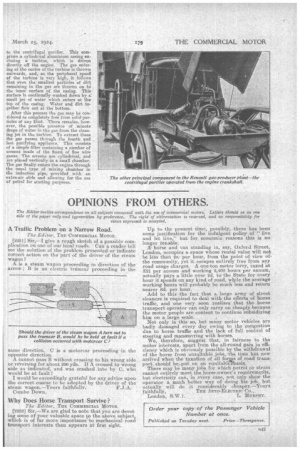

charcoal dust. The extractor can be rapidly opened and cleaned out, as the cover is held in place by four hinged bolts provided with winged nuts. The next stage of purification takes place in the scrubber. This consists of a large cylindrical chamber situated on the opposite side of the lorry to the generator. This chamber is fitted with

three trays or cages, each containing a quantity of small spirals of wire soaked in oil. The gas entering at the bottom passes upwards through this chamber, and the finer particles of dust which may have escaped -past the extractor ate deposited upori the spirals of wire.

It will be seenthat the total oily surface presented by the spirals is con

siderable. In the scrubber the same facilities for its c eaning may be noticed 'as are provided in the other portions of this apparatus. Six hinged bolts with butterfly nuts hold the lid in place, and when this is removed the cages of wire spirals can be extracted and cleaned in the shortest possible time. From the scrubber the gas passes on

to the centrifugal purifier. This comprises a cylindrical aluminium casing enclosing a turbine, which is driven directly off the engine. The gas entering at the centre of the turbine is thrown outwards, and, as the peripheral speed of the turbine is very high, it .follows that even the smallest particles of dirt, remaining in the gas are thrown on to the inner surface of the casing. This surface is continually washed down by al small jet of water which enters at the top of the caning. Water and dirt together flow out at the bottom.

After this process the gas may be considered as completely free from soh d particles of any kind. There remains, however, the possible presence of minute drops of water in the gas from the cleaning jet in the turbine. To extract these the gas passes through the fourth and last purifying appliance. This consists of a simple filter containing a number of screens made of the finest of fine wire gauze. The screens are cylindrical, and are placed vertically in a small chamber: The gas finally enters the engine through the usual type of mixing chamber in the induction pipe, provided with an extra-air slide and alloWing, for the use of petrol for starting purposes.