ANOTHER AMERICAN SIX-WHEELED BUS CHASSIS.

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

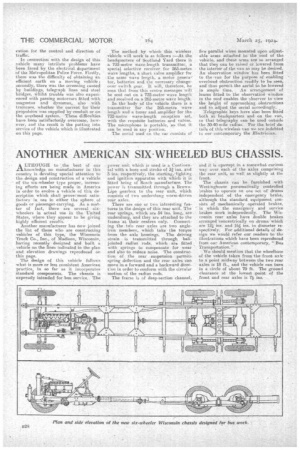

ALTIIOUGH to ,the beat of our knowledge no manufacturer in this country is devoting special attention to the-design and construction of a vehicle of the six-wheeler type proper, increasing efforts are being made in America in order to evolve a vehicle of this.descriptitin which shall provemost satisfactory in use in either the sphere, of goods or pissenger-carrying. As a matter of fact, there are several sixWheelers in actual use in the United States, where they appear to be giving highly efficient results.

Another manufacturer has now joined the list of those who are constructing vehicles of this type, the Wisconsin Truck Co., Inc., of Madison, Wisconsin, having recentlydesigned and built a vehicle on the lines indicated in the plan and elevation drawings reproduced on this page.

The design of this vehicle follows what is more or less consistent American practice, in so far as it incorporates standard components_ The chassis is expressly intended for bus service. The

power unit which is used is a Continental with a bore and stroke of 3,1 ins. acid 5 ins, respectively, the starting, -lighting and ignition apparatus with which it is -fitted being of Bosch manufacture. The power is transmitted. through. a BrownLipe gearbox to the rear unit, which consists of two underslun.g worm-driven rear. axles.

There are one or two interesting features in the design of this rear unit. Tlie rear springs, which are 54 ins, long, are underslung, and they are attached to the frame at their centres only. Connecting the two rear axles are two angleiron members which take the torque from the axle housings. The driving strain is transmitted through balijointed radius rods, which are fitted with springs to compensate for wear arid also to reduce noise. The construction of the rear suspension permits spring deflection and the rear axles can i move n a forward and a backward dimet=on in order to conform with the circular motion, of the radius rods.

The frame isof deep-section channel, and it is upswept in a somewhat curious way over each of the axles comprising the rear unit, as well as slightly at the front.

The chassis can be furnished with Westinghouse pneumatically controlled. • in:Mies to operate ori one set of drums independent of the emergency brake, although the standard equipment consists of mechanically operated brakes, in which the emergency and service brakes work independently. The Wisconsin rear axles have double brakes arranged 'concentrically on drums/which • are 12* ins. and 14 ins. in diameter respectively. For additional details of design we would refer our readers to the illustrations which have been reproduced from our American contemporary, "Bus Transportation."

We should mention that the wheelbase of the vehicle taken from-the front axle to a point midway between the two rear • axles is 18 ft., and the vehicle can turn in a circle of about 70 ft. The ground clearance at the lowest point of the front and rear axles is 74• ins.