Put your safety first

Page 88

Page 89

Page 90

If you've noticed an error in this article please click here to report it so we can fix it.

The basics are a well laid out shop with a level non-slip floor, but no one can avoid hazards unless attention is drawn to them. By Richard Longworth

• With common sense added to a number of precautions, no one should get hurt in a commercial vehicle workshop. Always read the instructions for use issued with equipment (and don't lose them).

No one can work quickly and efficiently in a badly laid out shop. First, the floor must be flat.

An easy-to-apply floor paint will provide a durable, non-slip surface that resists oils, fuels and acids. If a floor is not easy to clean, no one will bother, and a spillage is virtually inevitable.

Whether powered handtools are driven by electricity or compressed air they need a power point close to wherever they are likely to be used to avoid the workshop being strewn with trip-wires.

Anyone working in a workshop must take care of both himself and his workmates under the provisions of the 1974 Health and Safety at Work Act. This includes not doing something (such as taking a safety precaution) as weU as doing something dangerous. Therefore if you hurt yourself you may be breaking the law. Under the same Act, anyone who designs, manufactures, imports or supplies anything for use at work must make sure that it is safe, but escapes liability if it was not being used as instructed.

Safety equipment should match every potential hazard. Fire extinguishers come in five different colours, signifying suitabilty for five different types of fire. The traditional red extinguisher uses water, and although adequate for putting out burning wood or fabric, but will give a nasty shock if used on an electrical fire, and is useless on burning liquids.

The cream-coloured extinguisher uses foam, and can be used on liquids, but not on electrical fires. The blue, black and green extinguishers are the best for workshop use. Using powder, carbon dioxide and halon respectively, they can be used on electrical and liquid fires. A fire blanket is a good investment as a back up.

Where acid is used, there must be a supply of soda ash to neutralise spillages, and a supply of water. If there is not a tap nearby, a water tank will do provided the water is changed regularly, and is not used for washing hands, or quenching hot metal.

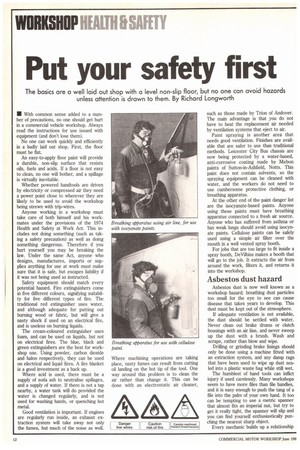

Good ventilation is important. If engines are regularly run inside, an exhaust extraction system will take away not only the fumes, but much of the noise as well. Where machining operations are taking place, nasty fumes can result from cutting oil landing on the hot tip of the tool. One way around this problem is to clean the air rather than change it. This can be done with an electrostatic air cleaner, such as those made by Trion of Andover. The main advantage is that , you do not have to heat the replacement air needed by ventilation systems that eject to air.

Paint spraying is another area that needs good ventilation. Finishes are available that are safer to use than traditional methods. Leicester City Bus chassis are now being protected by a water-based, anti-corrosive coating made by Mebon paints of Sutton-in-Ashfield, Notts. This paint does not contain solvents, so the spraying equipment can be cleaned with water, and the workers do not need to use cumbersome protective clothing, or breathing apparatus.

At the other end of the paint danger list are the isocyanate-based paints. Anyone using these paints must have breathing apparatus connected to a fresh air source. Anyone who has suffered from asthma or has weak lungs should avoid using isocynate paints. Cellulose paints can be safely used using a simple air filter over the mouth in a well vented spray booth.

For jobs that are too large to fit inside a spray booth, DeVilbiss makes a booth that will go to the job. It extracts the air from around the work, filters it, and returns it into the workshop.

Asbestos dust hazard

Asbestos dust is now well known as a workshop hazard; breathing dust particles too small for the eye to see can cause disease that takes years to develop. This dust must be kept out of the atmosphere.

If adequate ventilation is not available, the dust should be settled with water. Never clean out brake drums or clutch housings with an air line, and never sweep up the dust with a brush. Wash and scrape, rather than blow and wipe.

Drilling or grinding brake linings should only be done using a machine fitted with an extraction system, and any damp rags that have been used to wipe up dust sealed into a plastic waste bag while still wet.

The humblest of hand tools can inflict injury if used carelessly. Many workshops seem to have more files than file handles, and it is easy enough to push the tang of a file into the palm of your own hand. It too can be tempting to use a metric spanner that almost fits an imperial nut, but try to get it really tight, the spanner will slip and you can find yourself enthusiastically punching the nearest sharp object.

Every mechanic builds up a relationship with his tools, always having favourite ones. Unfortunately these are the ones that will wear out first, so when the jaws of a well used spanner start to spread, it is best replaced before it starts to roundoff nuts, and injure fingers. An adjustable spanner almost fits everything, but fits nothing exactly, so should be used only as a last resort.

Clothing plays a vital role in protecting the mechanic from workshop hazards. Overalls do much more than just keeping clothes clean. Oil and grease can cause cancer, so it is vital to keep overalls clean. Every operative should have three pairs worn in rotation, and as washing removes only around half the impregnated dirt, they should be dry cleaned.

Overall pockets should be used with care. Plunging a hand into a tool filled pocket can be fraught with hazard, but worst of all, carrying an oily rag about in a pocket can cause cancer of the scrotum and bowel. Tatty overalls are also a menace as they can easily get caught up in revolving machinery and take some if not all of the wearer with them.

Long hair is also a painful way to get caught up in your tools. You may look daft in a hair-net, but not as daft as with a bald patch. When working beneath a vehicle, whether using a lift or a pit, a helmet can save a lot of pain, although if the peak is too large, it may cause neck-ache.

Eye protectors

Anyone who works beneath vehicles will be familiar with the problems of dirt falling into the eye. Since the introduction of the Protection of Eyes Regulations in 1975, eye protectors must be issued by the employer on a personal basis for use with most processes involving machine tools. It is a good idea to maintain your own pair of safety spectacles whatever you are doing in the workshop.

The pair of goggles, hanging on a rusty nail above the grinding wheel, and slowly filing with dust are worse than useless. If the safety goggles will not fit comfortably over a pair of glasses, safety goggles are available with optically ground safety lenses that can be made to any prescription.

Apart from the general purpose goggle, there are two grades of impact goggle, a molten metal goggle, a chemical goggle, a dust goggle and gas tight goggles. Failure to use eye protection provided renders the offender liable to prosecution.

Welding, particularly with electricity, obviously requires special face masks, but it is easy to damage the eyes when the heavily tinted face mask is removed and the hot slag is chipped from an arc weld. Screens should be erected around any arc welding activity, to prevent passers-by catching a glimpse, and at best seeing a dot in front of them for the rest of the day, and at worst getting the dreaded "arc-eye". No charge can be levied by the employer for the issue, upkeep or replacement of eye protection required by the protection of eyes regulations.

Steel toecapped boots with oil resistant soles must be worn. Trainers may be more comfortable, but the workshop is so full of sharp and heavy objects, that damage to an unprotected foot is inevitable sooner or later.

The most abused tools are often the mechanic's hands, and unless care is taken, they may fall foul of the dreaded dermatitis. Ugly persistent and very uncomfortable, dermatitis causes more lost production time than any other industrial disease. The skin protects the body from poisons and infection mainly with the aid of two substances, fat and keratin.

Both of these essential natural substances are attacked by substances used in the workshop. Weak alkali solutions, such as many cutting oils, will break down keratin, and solvents such as petrol, paraffin or naptha disolve the fat. Although degreasing plant may be an effective way of cleaning hands, it leaves them damaged and vulnerable to the next dose of dirt they come in contact with.

Before starting work, at the same time as putting on overalls, barrier cream should be rubbed well into the pores of the skin and around the fingernails. Traditional detergent-based hand cleansers such as Swarfega are very effective, but tend to dry out the skin, so should be used with an after-work cream. The new generation of hand cleaners such as Comma Manista contain lanolin, leave the skin supple and ready to resist the next chemical assault.

If there are too many cooks in a workshop, the brew can be lethal. A Freight Transport Association inspector recently climbed down from a truck cab, to find that a crawler-board had been left at the bottom of the steps. Stepping on what he assumed to be solid ground, he went flying. Before getting beneath a vehicle always disconnect the battery, and leave a notice on the steering wheel saying where you are.

For people new to the workshop, the Motor Agents Association publishes a guide which stresses fundamentals such as always inflating commercial vehicle tyres inside a cage or behind a guard, and using rigid supports to prop open a cab.

The Road Transport Industry Training Board pubishes three booklets concerning health and safety, four videos (also available as a tape with slides) outlining workshop hazards and how to avoid them, and a portable training course with a revision exercise for up to 20 people. The videos can be hired or bought, but the booklets and training pack must be bought (the booklets start at 21).

The main responsibility for seeing that the law on health and safety at work is observed, belongs to the Health and Safety Executive. It operates from a network of 20 offices throughout Britain, reviewing work practices and giving advice and guidance. Where necessary, it will issue enforcement notices and institute prosecutions.

The HSE is responsible for carrying out the policies of the Health and Safety Commission, which is made up of eight representatives of trade unions, employers and local authorities. The chairman is appointed by the Secretary of State for Employment.

For all the rules and regulations, there is only one person who can make the real difference between a safe and dangerous work place, and that is the person who is doing the work.

No one can avoid workshop hazards unless attention is drawn to them. Since the beginning of 1986, all safety signs have to conform to BS 5478. Red signs are prohibitive: if you are doing something that is described in red, stop. Blue signs describe mandatory activities, ones that must be done, such as wearing a helmet, and green signs signify a safe activity. A yellow sign means a risk of danger, and outlines what that hazard is. The full range of these signs is available from Focal Displays of Mitcham in Surrey.

Another source of warning posters is the Royal Society for the Prevention of Accidents (RoSPA), which publishes a comprehensive range of safety literature. In addition to the usual safety signs, it sells a range of posters which graphically illustrate the hazards of careless behaviour; most workshop injuries are self inflicted.