ON THE MOVE

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

T Brady and Son is one of the old guard — a third generation family haulage business with long-established systems and a strong local customer base: but it's still light on its feet.

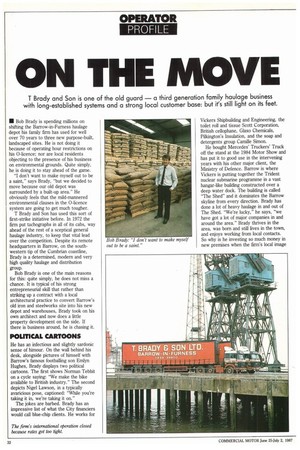

MI Bob Brady is spending millions on shifting the Barrow-in-Furness haulage depot his family firm has used for well over 70 years to three new purpose-built, landscaped sites. He is not doing it because of operating hour restrictions on his 0-licence; nor are local residents objecting to the presence of his business on environmental grounds. Quite simply, he is doing it to stay ahead of the game.

"I don't want to make myself out to be a saint," says Brady, "but we decided to move because our old depot was surrounded by a built-up area." He obviously feels that the mild-mannered environmental clauses in the 0-licence system are going to get much tougher.

T Brady and Son has used this sort of first-strike initiative before. In 1972 the firm put tachographs in all of its cabs, way ahead of the rest of a sceptical general haulage industry, to keep that vital lead over the competition. Despite its remote headquarters in Barrow, on the southwestern tip of the Cumbrian coastline, Brady is a determined, modern and very high quality haulage and distribution group.

Bob Brady is one of the main reasons for this: quite simply, he does not miss a chance. It is typical of his strong entrepreneurial skill that rather than striking up a contract with a local architectural practice to convert Barrow's old iron and steelworks site into his new depot and warehouses, Brady took on his own architect and now does a little property development on the side. If there is business around, he is chasing it.

POLITICAL CARTOONS

He has an infectious and slightly sardonic sense of himour. On the wall behind his desk, alongside pictures of himself with Barrow's famous footballing son Emlyn Hughes, Brady displays two political cartoons. The first shows Norman Tebbit on a cycle saying: "We make the bike available to British industry." The second depicts Nigel Lawson, in a typically avaricious pose, captioned: "While you're taking it in, we're taking it on."

The jokes are barbed. Brady has an impressive list of what the City financiers would call blue-chip clients. He works for The firm's international operation closed because rates got too tight. Vickers Shipbuilding and Engineering, the toilet roll and tissue Scott Corporation, British cellophane, Glaxo Chemicals, Pilkington's Insulation, and the soap and detergents group Camille Simon.

He bought Mercedes' Truckers' Truck off the stand at the 1984 Motor Show and has put it to good use in the intervening years with his other major client, the Ministry of Defence. Barrow is where Vickers is putting together the Trident nuclear submarine programme in a vast hangar-like building constructed over a deep water dock. The building is called "The Shed" and it dominates the Barrow skyline from every direction. Brady has done a lot of heavy haulage in and out of The Shed. "We're lucky," he says, "we have got a lot of major companies in and around the area." Brady thrives in the area, was born and still lives in the town, and enjoys working from local contacts. So why is he investing so much money in new premises when the firm's local image is so good? "I don't like that we should go on allowing people to think of us as rough and ready hauliers. We're not, we're businessmen." The new depot will be impressive. An old stone archway which used to grace the entrance to the steelworks has been carefully dismantled and will be rebuilt by Brady as a special feature on the new site. There will also be grassed screen banks, trees and a duck pond in the new truck yard.

BREATHING SPACE

The firm wants to expand and it believes that the move will give it plenty of breathing space. It is moving from 85,000m2 of site space to 150,000m2, and a new link road will be built next to the new site to help keep vehicles out of the town centre.

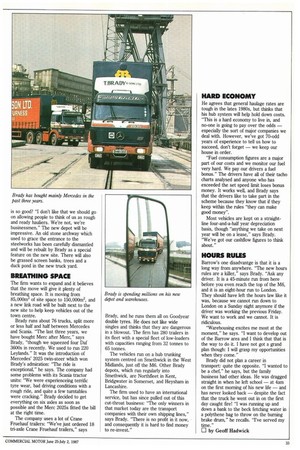

Brady runs about 76 trucks, split more or less half and half between Mercedes and Scania. The last three years, we have bought Merc after Merc," says Brady, "though we squeezed four Daf 3600s in recently. We used to run 220 Leylands." It was the introduction of Mercedes' 2025 twin-steer which won Brady's admiration: "The ride is exceptional," he says. The company had some problems with its Scalia tractor units: "We were experienceing terrific tyre wear, bad driving conditions with a rough ride, and quite a few turntables were cracking." Brady decided to get everything on six axles as soon as possible and the Merc 2025s fitted the bill at the right time.

The company uses a lot of Crane Fruehauf trailers: "We've just ordered 18 tri-axle Crane Fruehauf trailers," says Brady, and he runs them all on Goodyear double tyres. He does not like wide singles and thinks that they are dangerous in a blowout. The firm has 280 trailers in its fleet with a special fleet of low-loaders with capacities ranging from 32 tonnes to 65 tonnes.

The vehicles run on a hub trunking system centred on Smethwick in the West Midlands, just off the M6. Other Brady depots, which run regularly into Smethwick, are Northfleet in Kent, Bridgwater in Somerset, and Heysham in Lancashire.

The firm used to have an international service, but has since pulled out of this cut-throat business: "The only winners in that market today are the transport companies with their own shipping lines," says Brady. "There is no profit in it now, and consequently it is hard to find money to re-invest."

HARD ECONOMY

He agrees that general haulage rates are tough in the lates 1980s, but thinks that his hub system will help hold down costs. "This is a hard economy to live in, and no-one is going to pay over the odds — especially the sort of major companies we deal with. However, we've got 70-odd years of experience to tell us how to succeed, don't forget — we keep our house in order.

"Fuel consumption figures are a major part of our costs and we monitor our fuel very hard. We pay our drivers a fuel bonus." The drivers have all of their tacho charts analysed and anyone who has exceeded the set speed limit loses bonus money. It works well, and Brady says that the drivers like to take part in the scheme because they know that if they keep within the rules "they can make good money".

Most vehicles are kept on a straightline four-and-a-half year depreciation basis, though "anything we take on next year will be on a lease," says Brady. "We've got our cashflow figures to think about."

HOURS RULES

Barrow's one disadvantge is that it is a long way from anywhere. "The new hours rules are a killer," says Brady. "Ask any driver. It is a 45-minute run from here before you even reach the top of the M6, and it is an eight-hour run to London. They should have left the hours law like it was, because we cannot run down to London on a Sunday night anymore if the driver was working the previous Friday. We want to work and we cannot. It is ridiculous.

"Warehousing excites me most at the moment," he says. "I want to develop out of the Barrow area and I think that that is the way to do it. I have not got a grand plan though: [will grasp my opportunities when they come."

Brady did not plan a career in transport: quite the opposite. "I wanted to be a chef," he says, but the family business had other ideas. He was dragged straight in when he left school — at 4am on the first morning of his new life — and has never looked back — despite the fact that the truck he went out in on the first day caught fire! "I was running up and down a bank to the beck fetching water in a polythene bag to throw on the burning brake drum," he recalls. "I've served my time."

o by Geoff Hadwick