Seddon Sets a New mdard in Economy

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

WITH a small, high-efficiency oil engine and a high rearaxle ratio it is to be expected that fuel consumption will be low. But the Seddon 25-cwt. chassis which I tested exceeded everybody's expectation by returning a consumption rate of 48.9 m.p.g. when running continuously at 31.1 m.p.h. with a gross weight of 2 tons In cwt. This result was not a mere chance, as was proved later in the day when taking part-load figures.

Such economy sets a new standard to be reached for vehicles of this class and demonstrates just what can be achieved when a happy combination of engine and transmission is made. The Seddon is also a lively vehicle and there has been no skimping of detail in order to bring the unladen weight down to just over li tons.

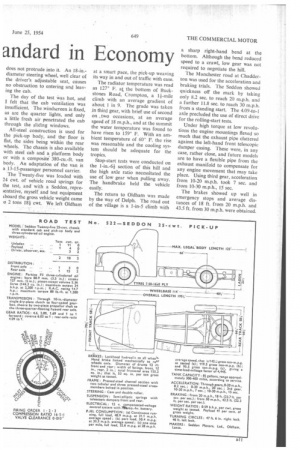

This model was first shown to thepublic at the Scottish Show in November, 1953, but since then it has undergone numerous modifications, not the least of these being in its appearance. It is not unpleasant to look at and an impression of power is conveyed by the large front overhang. The front axle is placed behind the engine, thus improving weight distribution and handling.

The Perkins P.3 oil engine develops 88 lb.-ft. torque at 1,200 r.p.m. and hasa power output of 34 b.h.p. at the 2,400 r.p.m. governed speed. Its construction follows standard Perkins practice, with a 3.5-in, bore and 5-in, stroke, and particular attention has been paid to balancing the crankshaft. When running, except under maximum load, the engine is smooth enough to be taken for a fourcylindered unit.

It is mounted, as is normal, as a unit with the four-speed constantMesh gearbox. This has been stO specially designed for the Seddon and requires no modification to fit the Perkins bell-housing.

Four-point mounting by Metalastik sandwich units in compression and shear, is used. The front mounting brackets are bolted to each side of the block, whilst those at the rear are attached to the bell-housing casting. No torque snubbers are fitted.

A 10-in, clutch is hydraulically operated from a master cylinder mounted on the engine bulkhead. This cylinder is adjacent to the brake master cylinder, and pendant pedals are used, these providing ample leverage and smooth action.

The 4.09-to-1 hypoid-bevel-gear rear axle has a high efficiency rating and doubtless contributes to the low fuel consumption. It is driven through a two-piece propeller shaft having universal couplings at centre and rear and a flexible rubber coupling behind the gearbox. The centre bearing is supported on flexibly-mounted trunnions.

Suspension is by long semielliptic springs mounted on rubberbonded bushes. The rear springs are underslung and the anchor brackets are bolted below the frame members, thus allowing a wide frame at the rear and increasing stability. Telescopic dampers are fitted as standard to both axles and the suspension is effective over all road surfaces.

Lockheed brakes act on 12-in.diameter drums at the front and rear. A longitudinal member placed between the second and third chassis cross-members carries the handbrake lever to the left of the driver.

The cab, wings and bonnet are all of steel, and engine accessibility is good. A simple radiator grille is now used, providing a greater air-intake area than with the original grille. The cab is sufficiently wide to scat three persons and the engine cowling does not protrude into it. An 18-in.diameter steering wheel, well clear of the driver's adjustable seat, causes no obstruction to entering and leaving the cab.

The day of the test Was hot, and I felt that the cab ventilation was insufficient. The windscreen is fixed, as are the quarter lights, and only a little fresh air penetrated the cab through the sliding windows.

All-steel construction is used for the pick-up body, and the floor is flat, the sides being within the rear wheels. The chassis is also available with steel cab and a platform body or with a composite' 380-cu.-ft. van body. An adaptation of the van is a 13-15-passenger personnel carrier.

The Twenty-five was loaded with 24 cwt. of vehicle road springs for the test, and with a Seddon repre;entative, myself and test equipment tboard the gross vehicle weight came o 2 tons 18i cwt. We left Oldham at a smart pace, the pick-up weaving its way in and out of traffic with ease.

The radiator temperature was read as 127* F. at the bottom of Buckstones Road, Crompton, a climb with an average gradient of about 1 in 9. The grade was taken in third gear, with brief use of second on two occasions, at an average speed of 18 m.p.h., and at the summit the water temperature was found to have risen to 159° F. With an arnbient temperature of 60° F. the rise was reasonable and the cooling system should be adequate for the tropics.

Stop-start tests were conducted on the 1-in.-6+ section of this hill and the high axle ratio necessitated the use of low gear when pulling away. The handbrake held the vehicle easily.

The return to Oldham was made by the way of Delph. The road out of the village is a 1-in-5 climb with a sharp right-hand bend at the bottom. Although the bend reduced speed to a crawl, low gear was not required to negotiate the hill.

The Manchester road at Chadderton was used for the acceleration and braking trials. The Seddon showed quickness off the mark by taking only 8.2 sec. to reach 20 m.p.h. and a further 11.8 sec. to reach 30 m.p.h. from a standing start. The 4.09-to-1 axle precluded the use of direct drive for the rolling-start tests.

Under high torque at low revolutions the engine mountings flexed so much that the exhaust pipe clattered against the left-hand front telescopic damper casing. These were, in any case, rather close, and future models are to have a flexible pipe from the exhaust manifold to compensate for any engine movement that may take place. Using third gear, acceleration from 10-20 m.p.h. took 7 sec. and from 10-30 m.p.h., 15 sec.

The brakes showed up well in emergency stops and average distances of 18 ft. from 20 m.p.h. and 43.5 ft. from 30 m.p.h. were obtained. Wheel-lock was not pronounced and there was no deviation from a straight course. The retardation rate born 30 m.p.h. is equivalent to 0.7g. and the Tapley meter reading of 42 per cent. for the hand brake when applied at 20 m.p.h. showed the brakes to be well up to the general standard of the vehicle.

But the highlight of the day was when I found that only 1.7 pints of fuel were required to top up the tank after a continuous run of 10.4 miles. The circuit over which this test was run was between Chadderton and Heaton Park and back and although fairly level for the most part, it includes a hill which twice required the use of third gear. Traffic lights and roundabouts also caused use of the gearbox and on the first run the Seddon was brought to a halt on two occasions.

Consequently, 48.9 m.p.g., with an average speed of 31.1 m.p.h., is not an optimistic figure. This view is supported by the result obtained after a run over the same circuit with a payload of 13 cwt. On this occasion the figure was 50.4 m.p.g. and the average speed was higher (33.3 m.p.h.). Had I not restrained the driver, an even higher speed would have been maintained, because the engine was running easily at speeds in excess of 40 m.p.h.

Before the part-load run was made, a one-stop-per-mile test was made with full load over the full course, and this time topping-up required 2.55 pints of fuel, equivalent to 32.6 m.p.g. This is still an excellent return, although rather overshadowed by the continuous-running results, and proves the Seddon to be economical on local delivery. These tests show that once the vehicle is moving the Perkins engine requires very little fuel to keep the speed up and even with increased use of the indirect ratios a remarkably low consumption figure is obtained. The all-round performance is commendable, and for moving 1 tons from one place to another swiftly and cheaply, the Seddon Twenty-five will take a lot of beating.