THE BODYWORK' .NGLE ON OPERATORS' PROBLEMS

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

PREVENTING the floor of the lorry from becoming sodden is a problem which sometimes has to be solved on such occasions as when there is a considerable amount of moisture in the load, or some spillage is inevitable, as with a milk vehicle.

In order to prevent moisture from remaining on the floor, the top surface of the cross-bearers is not horizontal, but is sloped for about 1 in. from each end to the centre. The longitudinal centre ,line of the floor may have holes at intervals, so that accumulated moisture may readily escape, or the water may be collected in a channel for discharge at one end.

When the floor is laid horizontally, gaps may be made between the edges of the floorboards. Another plan, which has the advantage that no ‘holes are required in the floor, consists of supporting the sides of the floor on an inner rail, which has a clearance between it and the bottom side, to which are framed the side pillars: Making Provision for the Escape of Water.

Both the bottom side and the inner rail are supported by the crossbearers, but the space of I in. or so between these two lengthwise rails provides an escape for water, which tends to find its way to the sides of the floor, owing to the• suction set up by the currents of air passing under • the vehicle while it is moving.

In a similar manner, moisture is. less likely to accumulate if there be no side ledges to the floor and there be a small space between the bottom of the side panelling and the floor. Free movement of water on the floor May be prevented by the wearing slats, in which small gaps may be left at intervals.

A front gantry facilitates the carrying of a lengthy load, such as boards or planks of timber. In many instances, however, only a portion of

the load is of this character p.nd the greater -part of the loading area is required for articles of Various sizes and shapes.

Such mixed loads are carried on the lorries of hardware and builders' merchants. It is an advantage if the piping and similar material be accommodated in a compartment specially designed for it.

Piping is often carried in a horizontal wood trough built outside the main loading portion, which is narrower than usual and is of the same overall width as the cab. This pipe trough may extend forward on one side across the cab-door area. '

Such accommodation may be increased by adding a second trough on one or both sides of the lorry. This slopes upwards and the front rests on the cross-bar of a gantry. Such a trough will hold longer pieces of iron than will a horizontal channel, without obstructing the cab doorways.

There may be a considerable tendency for the sides, of the troughs to be forced apart by the pressure of the iron bars, piping and so forth,

accommodated between them. To withstand stresses of this nature it is a good plan to tie together the upper edges of the trough sides by means of inverted U pieces. These need to be of material that is stout enough to give them a reasonable degree of rigidity.

The fact that they prevent the direct lowering of bars into the troughs is of little consequence, whilst the arrangement outlined is stronger and simpler than employing angles at the bottom edges.

The type of lorry just described has fixed sides and the main loading area is somewhat restricted in width to provide space for the side troughs. This may be a disadvantage when no bar iron is carried and space is required for a -full load of miscellaneous material.

Arranging Cross-bearers in the Form of Arches.

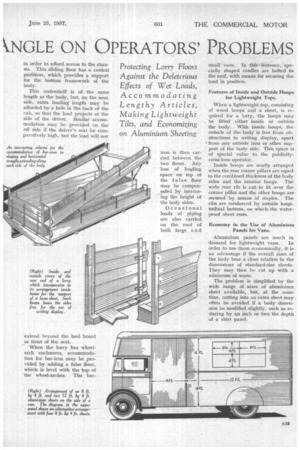

If a drop-sided lorry of the usual width be .pref erred, accommodation may be provided under the floor. With some lorries that have no wheel-arches, there is a space of about 10 ins, between the underside of the floor and the top of the chassis. This space may be utilized by designing the cross-bearers in the form of arches.

The shelf, on which the bar-iron rests between the side members of the chassis, is not fixed permanently, but arranged to slide out at the rear. in order to afford access to the chassis. This sliding floor has a central partition, which provides a support for the bottom framework of the body.

This uudershelf is of the same length as the body, but, on the near side, extra loading length may be afforded by a hole in the back of the cab, so that the load projects at the side of the driver. Similar accommodation may be provided on the off side if the driver's seat be comparatively high, but the load will not extend beyond the heel board or front of the seat.

When the lorry has wheelarch enclosures, accommodation for bar-iron may be provided by adding a. false floor, which is level with the top of the wheel-arches. The bar iron is then carried between the two floors. Any loss of loading space on top of the false floor may be compensated by increasing the height of the body sides.

Occasional loads of piping are also carried on the roof of both large a n d

small vans. In this instance, specially shaped cradles are bolted to the roof, with means for securing the load in position.

Features of Inside and Outside Hoops for Lightweight Tops.

When a lightweight top, consisting of wood hoops and a sheet, is required for a lorry, the hoops may be fitted either inside or outside the body. With inside hoops, the outside of the' body is free from obstructions to writing display, apart ■ from any outside iron or other support of the body side. This space is of special value to the publicityconscious operator.

Inside hoops are neatly arranged when the rear corner pillars are equal to the combined thickness of the body sides and the interior hoops. The wide rear rib is cut to fit over the corner pillar and the other hoops are securedby means of staples. The ribs are reinforced by outside longitudinal battens, on which the waterproof sheet rests.

Economy in the Use of Aluminium Panels for Vans.

Aluminium panels are much in demand for lightweight vans. In order to use them economically, it is an advantage if the overall sizes of the body bear a close relation to the dimensions of standard-size sheets. They may then be cut up with a minimum of waste.

The problem is simplified by the wide range of isizes of aluminium sheet available, but, at the same time, cutting into an extra sheet may often be avoided if a body dimension be modified slightly, such as reducing by an inch or two the depth of a shirt panel.