IMPROVING CHASSIS DESIGN

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Points which Often Require Attention. How the Work of the Maintenance Engineer can be Facilitated. The Question of Accessibility.

By Engineer-designer.

WHERE may 'be some who consider 1 the duties of the maintenance engineer to be chiefly confined to maintaining the vehicles entrusted to his charge while they are in the garage ; this, however, is not the case. The maintenance engineer is just as responsible for delays that happen on the road as for work done in the garage. It is necessary, therefore, while considering what improvements are most urgently needed, to 'deal both with road and garage troubles, and how they can best be avoided.

The writer read with much interest the humorous account recently published in The Commercial Motor of the meeting of an imaginary dub of maintenance engineers, and considers that a little good-natured banter of this kind, with a certain amount of truth behind it, may have more effect in bringing about improvements than a more serious criticism. '

The question has recently been asked : " What results from continued improvement and who benefits? The answer to this is simply: It keeps the foreigner away from the home market and enables us to compete with him on the quality basis in foreign markets. There are certain trades in which our products are the best in the world. If one looks around at these trades it will be found that they are not wanting orders, whilst in those trades where we have either slipped behind or have never got to the front depression will usually be found.

To come down to the brass tacks of what improvements are most necessary for embodiment in future designs, the writer would say that accessibility and easy removability of all, units are probably points which should receive attention. In many instances an irritating quarter of an inch will prevent a unit such as a gearbox, clutch, etc., from being raised or lowered until: an engine or rear axle has been unbolted and slid away. In many cases the necessary amount could easily have been gained by lengthening th.; splines by a quarter of an inch, or in some other way enabling the collar on a shaft to be slid farther back so tint the unit coal.** Easily come out.

Probably the next point of importance is as to whether engines and gearboxes are better made separately or in the form of what is known as -unit construction. For a private ear the latter has many points to recommend it, but for a commercial vehicle, especially of the heavier type, the writer fails to see any real advantage in using it, the reason for this opinion being that the

writer would prefer a chassis in which every individual part that ig likely at any time to require attention or renewal is removable separately.

Where a short shaft separates the engine and gearbox this should have two universal joints, the parts of which can be detached easily, thus allowing the clutch to be removed. The rear joints should be capable of being dismantled shouldthe gearbox have to be removed. The universal joint immediately behind the gearbox should be constructed on similar lines. Should another universal joint be employed at the foremost end of the torque tube, this should also be capable of removal' without interfering with any of the other parts.

It is not impossible to design a gearbox that can be lowered from its position without disturbing the body, so why should any other type survive?

Many breakages of such parts as engine and gearbox arms can be traced to frame rack. The writer has often looked along a chassis when one fiont wheel is passing over an obstruction, and has wondered how a frame and body can possibly be expected to stand up to its work under such conditions. It may be said that the springs yield to an extent, but they can never yield sufficiently to relieve the frame and all parts that are fixed to it from very severe stress. Large tubular cross members may reduce the twisting to some slight extent, but if they do they only put more stress or. the side frames. The correct treatment of this trouble would appear to be the provision of some form of pivot which would allow the front axle to cant so that it can relieve the frame of all twisting ...tresses.

The form of central pivot which • ortens the front spring is not the

c rrect solution of the trouble or it wbuld have been generally adopted it' ore now. Something better than vi is wanted. The writer thinks that t s point is one that has escaped the

a cation of designers, as the provision o such pivots has up to now been consi ered necessary only for vehicles that a, to be used in undeveloped countries. exibility has been provided in most o er parts of the chassis, so why not ovide -for it here where, the greatest ount of distortion is known to take pl ce?

With regard to engines, the writer Ii's not much fault to find with the iii thuds of construction at present em pl yed. The engine, although the most co unlimited part of the whole machine, at ange to say, usually gives the least tr uble to the niaintenanee man. This in y be accounted for by the fact that th • engine is the pampered child of the

d igner's brain, which occupies so in eh of his attention that other parts or apt to be neglected.

There is, however, one point in en hies that would seem to require atte tion—that is, the poor finish usually gi en to the surfaces of the bearings,

b h big-ends and main ; they are us ally left as they come from the gr nding wheel, and if examined with a P -erful glass will be found to be a se les of hollows and high spots. Such Cu 'faces would not pass for the rollers OE balls of bearings, which are finished to a looking-glass polish. The writer had experience of engines the bearin s of which have been.finished in this

• y, the results from Which were far • ad of those obtained from ordinary

.ci nkshafts.

o finish the big-end bearings in this en nner may present some difficnity, hut it is not impossible,although to treat the nv in bearings is quite an easy matter. A yone who has had experience of using a burnisher on soft metals will know th t unless the burnisher has a perfect _ en lace, free from all defects, it will ea Ise abrasion of the soft metal: A. pe ect looking-glass polish has been

found necessary for, the bearings of high-class clocks and watches, so why not for motor engines?

With regard to brakes, it is strange that, where power has to be wasted, as in a . brake, engineers should find it necessary in many instances to introduce the operating effort from some outside source. It would seem evident that power to be expended in arresting • motion might be utilized to cause its own friction, as in the strictly selfenergizing type; The writer feels sure that in the near future we shall have .stune form Of 'simple self-energising : brake which will employ the power it absorbs to assist in its own application, instead of the more or less complicated • fluid-pressure systems.

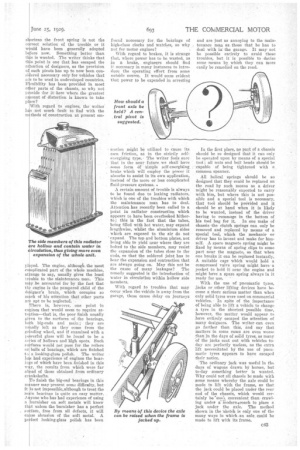

A certain amount of trouble is always to be found due TO leaking radiators, which is one of the troubles with which the maintenance man has to deal. Attention has recently been called to a point in radiator construction which appears to have been overlooked hitherto; this is the fact that the tubes, being filled with hot water, may expand lengthwise, whilst the aluminium sides which are exposed to the air do not expand. The top and bottom plates, not being able to yield near where they are bolted to the side members, may resist. the expansion of the tubes close to the ends, so that the soldered joint has to bear the expansion and contraction that are always going on. May this not be the cause of many leakages? The remedy suggested is the introduction of water in circulation within hollow side members.

With regard to troubles that may occur when the vehicle is away from the garage, these cause delay on journeys and are just as annoying to the maintenance man as those that he has to deal with in the gaiage. It may not be possible entirely to avoid these troubles, but it is possible to devise some means by which they can more easily be remedied on the road.

In the first place, no part of a chassis should be so designed that it can only be operated upon by means of a special tool; all nuts and bolt heads should be -capable of being tightened with a, common spanner.

All helical springs should be so designed that they could he replaced on the road by such means as a driver might be reasonably expected to carry with him, but where this is not possible and a special tool is necessary, that tool. should be provided and it should be at hand when it is likely to be wanted, instead of the driver having to rummage in the bottom of his tool bag for it. In one make of chassis .the clutch springs can only be removed and replaced by means of a special tool, which the mechanic or driver has to invent and make for himself. A spare magneto spring might be fixed by means of spring clips to some part near the magneto, so that when one breaks it can be replaced instantly.

.suitable cage which would hold a compressed valve spring might have. a pocket to hold it near the engine and might have a spare spring always in it ready for use.

With the use 'of pneumatic tyres, jacks or other lifting devices have become a More serious matter than when only solid tyres were used on commercial vehicles. In spite of the importance of being able to lift a vehicle to change a tyre in the Shortest possible time, however, the matter would appear to have entirely escaped the attention of many designers. The writer can even go farther than this, and say that matters in some cases are even worse than in the days of solid tyres, as many Of the jacks sent out with vehicles today are perfectly useless, as the extra lift necessitated by the use of pneumatic tyres appears to have escaped their notice.

The ordinary jack was useful in the days of wagons drawn by horses, but to-day something better is wanted. Why could not all chassis be made with some means whereby the axle could be made to lift with the frame, so that the jack could be placed under the rear end of the chassis, which would certainly be %IDA convenient than crawling under a inadernecoach to place a jack under the axle. The method shown in the 'sketch is only one of the many ways in which-an axle, could be made to lift with its frame.