TESTING

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

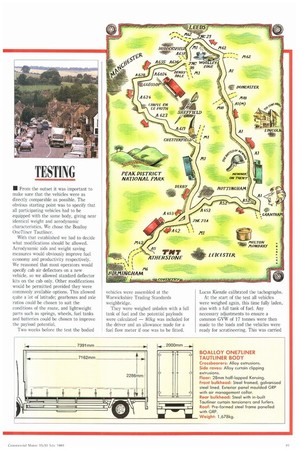

• From the outset it was important to make sure that the vehicles were as directly comparable as possible. The obvious starting point was to specify that all participating vehicles had to be equipped with the same body, giving near identical weight and aerodynamic characteristics. We chose the Boalloy One7liner Tautliner.

With that established we had to decide what modifications should be allowed. Aerodynamic aids and weight saving measures would obviously improve fuel economy and productivity respectively. We reasoned that most operators would specify cab air deflectors on a new vehicle, so we allowed standard deflector kits on the cab only. Other modifications would be permitted provided they were commonly available options. This allowed quite a lot of latitude; gearboxes and axle ratios could be chosen to suit the conditions of the route, and lightweight parts such as springs, wheels, fuel tanks and batteries could be chosen to improve the payload potential.

Two weeks before the test the bodied vehicles were assembled at the Warwickshire Trading Standards weighbridge.

They were weighed unladen with a full tank of fuel and the potential payloads were calculated — 80kg was included for the driver and an allowance made for a fuel flow meter if one was to be fitted. Lucas Kienzle calibrated the tachographs.

At the start of the test all vehicles were weighed again, this time fully laden, also with a full tank of fuel. Any necessary adjustments to ensure a common GVW of 17 tonnes were then made to the loads and the vehicles were ready for scrutineering. This was carried Out at TNT's Atherstone hub by their engineering staff. Specifications were checked and final adjustments made to tyre pressures.

The following morning, on Day One of the test all the vehicles were fuelled up by the fuel marshal Accurate filling was vital as we expected the final results to be very close. A separate dipstick was used for each tank and we were the first users of TNT's diesel pump since its recent calibration by Mobil, who also supplied the diesel.

Over the next two days fuelling took place at the same time each morning so that fuel temperature would be as near constant as possible.

Each entrant provided its own driver, who was accompanied by an observer, either from CM's technical team or by their opposite numbers from Verkehrs Rundschau and L'Officiel des Transports. Vehicles were set target times for each section, based on our trial runs over the route. The observers were briefed to make sure that the drivers kept to the speed limits but did not dawdle to save fuel. They also kept a count of gearchanges. Since the route had been published in advance, the entrants had been able to run round as often as they wanted to learn the directions.

The vehicles were sent off at three-minute intervals for the morning and afternoon sections, extending to six minutes for the hilly Peak District section.

At the end of each day Lucas Kienzle tacho experts carried out comprehensive chart analyses to get accurate running times for each truck, and to pick up any speeding or dawdling not picked up by the observers en route.

Any disputes were settled by the independent organising secretary, transport consultant Stan Thomas, who had been involved in previous CM economy runs.

Final fuelling took place on the third day. Outstanding adjustments for unavoidable delays was also made at this stage (two vehicles were stopped at a public weighbridge on day two) before the final results were calculated.