SPACE-SAVING -TONNER

Page 52

Page 53

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

conditions, together with such creature comforts as low engine noise, ample ventilation, and provision for fitting a heater and radio.

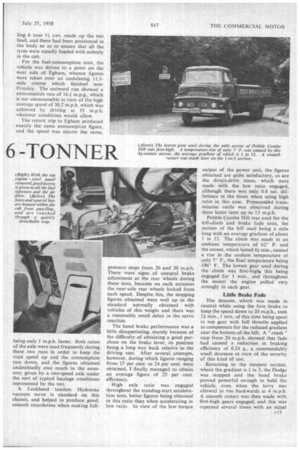

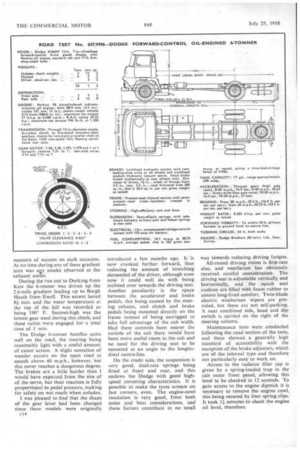

Following roughly the same design pattern as the normal-control range introduced in 1956, the Dodge forward-control range consists of 5-, 6and 7-tonners, offered with a variety of wheelbases and a choice of power units, including the Dodge 116-b.h.p. petrol engine in the case of the two lighter chassis. The complete range was fully described and illustrated in the March 7 issue of The Commercial Motor.

There are three basic 6-ton chassis: the 3126 13-ft. 7-in.-wheelbase model as tested; the 3125 II-ft. 81-in.-wheel c12

more suitable for very hilly service. The Mark 11c axle has ratios of 6.14 and 8.52 to 1. The standard tyres on the 3126 chassi.S. are 7.50-20 in. (12-ply.) equipment, and these tyres restrict the permissible gross weight to 9 tons 12 cwt. To obtain the •maximum permissible gross vehicle weight of 9 tons 161 cwt. it is necessary to fit 8.25-20-in. (12-ply) tyres, these permitting a full 6-ton payload to be carried.

Other optional equipment fitted to the test vehicle included front-spring dampers, rear helper springs, 35-gal. fuel tank (instead of the standard 17-gal. tank), flashing direction indicators, chromium-plated front bumper and twin sun vizors, these being of tinted plastics.

Mounted with a standard Dodge 17-ft. 6-in, drop-sided timber body, the 6-tonner had a kerb weight of 3 tons 12+ Cwt., the front axle loading being 1 ton 19+ cwt. Concrete blocks total being only 1 m.p.h. faster. Both ratios of the axle were used frequently during these two runs in order to keep the road speed up and the consumption rate down, and the figures obtained undoubtedly owe much to the economy given by a two-speed axle under the sort of typical haulage conditions represented by the test.

A Lockheed tandem Hydrovac vacuum servo is standard on this chassis, and helped to produce good, smooth retardation when making full

pressure stops from 20 and 30 m.p.h. There were signs of unequal brake adjustment at the rear wheels during these tests, because on each occasion the near-side rear wheels locked from each speed. Despite this, the stopping figures obtained were well up to the standard normally obtained with vehicles of this weight and there was a reasonably small delay in the servo reaction.

The hand brake performance was a little disappointing, mainly because of the difficulty of obtaining a good purchase on the brake lever, its position being, a long way back relative to the driving seat. After several attempts, however, during which figures ranging from 17 per cent. to 24 per cent. were obtained, I finally managed to obtain an average figure of 25 per cent. efficiency.

High axle ratio was engaged throughout the standing-start acceleration tests, better figures being obtained in this ratio than when accelerating in low ratio. In view of the low torque output of the power unit, the figures obtained are quite satisfactory, as are the direct-drive times, which were made with the low ratio engaged, although there was only 0.8 sec. difference in the times when using high _ratio in this case. Pronounced transmission rattle was observed during these latter tests up to 13 m.p.h.

Pebble Combe Hill was used for the hill-climb and brake fade tests, the section of the hill used being a mile long with an average gradient of about 1 in 12. The climb was made in an ambient temperature of 62° F. and the ascent, which lasted 41 min., caused a rise in the coolant temperature of only 7° F., the final temperature being 186° F. The lowest gear used during the climb was first-high" this being engaged for 1 min., and throughout the ascent the engine pulled very strongly in each gear.

Little Brake Fade The descent, which was made in neutral while using the foot brake to keep the speed down to 20 m.p.h., took 24 min., 1 min. of this time being spent in top gear with full throttle applied to compensate for the reduced gradient near the bottom of the hill. A "crash " stop from 20 m.p.h. showed that fade had caused a reduction in braking efficiency of 0.24 g., a commendably small decrease in view of the severity of this kind of test.

Returning to the steepest section, where the gradient is 1 in 5, the Dodge was stopped and the hand brake proved powerful enough to hold the vehicle, even when the lorry was allowed to run backwards at 4 m.p.h. A smooth restart was then made with first-high gears engaged, and this was repeated several times with an equal

measure of success on each occasion. At no time during any of these gradient tests was ay smoke observed at the exhaust outlet.

During the run out to Dorking from Kew the 6-tonner was driven up the 2.6-mile gradient leading up to Burgh Heath from Ewell. This ascent lasted 8+ min. and the water temperature at the top of the hill was recorded as being 190° F. Second-high was the lowest gear used during this climb, and these ratios were engaged for a total time of 1 min.

The Dodge 6-tonner handles quite well on the road, the steering being reasonably light with a useful amount of caster action. A slight sensation of wander occurs on the open road at speeds above 40 m.p.h., however, but this never reaches a dangerous degree. The brakes are a little harder than I would have expected from the size of of the servo, but their reaction is fully proportional to pedal pressure, making for safety on wet roads when unladen.

I was pleased to find that the shape of the gear lever had been changed since these models were originally c14 introduced a few months ago. Iris now cranked further forward, thus reducing the amount of stretching demanded of the driver, although even now it could well do with being inclined over towards the driving seat. Another peculiarity is the space between the accelerator and brake pedals, this being caused by the steering column, and clutch and brake pedals being mounted directly on the frame instead of being outrigged to take full advantage of the cab width. Had these controls been nearer the outside of the cab there would have been more useful room in the cab and no need for the driving seat to be mounted at an angle to the longitudinal centre-line.

On the credit side, the suspension is very good, dual-rate springs being fitted at front and rear, and this endows the Dodge with good highspeed cornering characteristics. It is possible to make the tyres scream on fast corners, even. The engine-cowl insulation is very good, from both noise and heat considerations, and these factors contribute in no small way towards reducing driving fatigue.

All-round driving vision is first-rate also, and ventilation has obviously received careful consideration. The driving seat is adjustable vertically and horizontally, and the squab and cushion are filled with foam rubber to ensure long-lived comfort. Twin-blade electric windscreen wipers are provided, but these are not self-parking. A neat combined side, head and dip switch is carried on the right of the steering column.

Maintenance tests were conducted following the road section of the tests, and these showed a generally high standard of accessibility with the exception of the brake adjusters, which are of the internal type and therefore not particularly easy to Work on.

Access to the radiator filler cap is given by a spring-loaded trap in the cab outer front panel, allowing this level to be checked in 12 seconds. To gain access to the engine dipstick it is necessary to remove the engine cowl, this being secured by four spring clips. It took 11 minutes to check the engine oil level, therefore. Combined filler and level plugs are fitted to the gearbox and rear axle, and these two levels were checked in 52 seconds and 55 seconds respectively. The reservoir for the clutch-actuation hydraulic circuit is below the cab floor, on the driver's side, and its cap can be reached from outside by stretching over the off-side, front wheel, this allowing the level to be checked in 42 seconds.

The brake fluid reservoir cap protrudes through the cab floor, close to the driving seat, and this level takes only 12 seconds to check. The two 6-volt batteries are stowed in a cradle on the off-side frame member, immediately behind the cab, and access to the cell plugs is given by removing the two covers, each being secured by two simple spring clips.

The electrolyte levels took me two minutes 40 seconds to check, a mirror being advisable for this operation because of the closeness of the batteries to the underside of the body.

The engine cowl takes 20 seconds to detach and lift out of the cab, and with this off I was able to check the air-cleaner oil level in 30 seconds, following which I removed No. 5 fuel injector in 11 minutes and replaced it in 1 minute 20 seconds. As with all Perkins engines, simple injector removal is a strong point, the injectors being located vertically in the head.

I was unable to remove the main fuel filter element because it is awkwardly placed at the front-left corner of the engine, where it cannot be reached easily from above or below. In its present position the only satisfactory way of reaching the filter is to remove the left-hand lower cowl panel, which is secured by no fewer than 11 bolts and screws, some of which are very difficult to reach without a short screwdriver. The filter might be stripped without disturbing the lower cowl by using two men, however, assuming that two men can be spared for such a job.

The engine cowl took 2+ minutes to refit, mainly because of the difficulty in aligning it so that the four fasteners could be locked up, and I then turned my attention to the spare wheel, which I removed in 2+ minutes and restowed in the same time. The wheel is secured in place by two bolts, which are fitted by the wheel-brace and which are on top of the wheel, thereby dispensing with the need to lie down when removing them. Brake adjustment proved to be no easy matter with the standard tools supplied in the tool kit. I managed to get the front brakes adjusted in 17 minutes, but was unable to touch the rear units because the screwdriver which fitted the slots in the adjusters on the front brakes did not fit those in the rear brakes. If brakes with external adjusters cannot be fitted to this chassis, the next best thing is that special tools should be provided in what is an otherwise good tool kit.

As a final task I removed and replaced a fuse in 30 seconds, the fuses being housed ahead of the driver in the frontal double-skin, access to them being given by a small plate held in place by two simple push fasteners.

The Dodge 3126P chassis, complete with standard cab, has a basic price of £1,298, plus £275 12s. 4d. purchase tax. The 17-ft. 6-in, body fitted to the test vehicle costs £105, and the Eaton 1350 two-speed axle adds £61 5s. (including tax) to the total price. The 8.25-20-in. (12-ply) tyres cost £18 (plus £3 17s. 2d. tax) in addition to the basic price when fitted on the standard B6.0 two-piece wheels, and £26 (plus £5 1 ls. 5d. tax) when mounted on B6.5 three-piece wheels.