HINTS ON MAINTENANCE.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will he paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for it running. Expedients and suggestions for overcoming roadside and other troubles are 'covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed to " The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, E.C.1."

239.—The Care Required by Wood Wheels.

in view of the large number of wood wheels utilized on motor vehicles, particularly those of American manufacture, it is desirable that users should know how to make the most of these wheels by preserving them in good condition. Wood wheels will give good service if well looked after, but they certainly require more attention than do most metal wheels, and they deteriorate rapidly unless they are kept well painted. An occasional application of linseed oil after cleaning will preserve the paint and keep the wheels waterproof. If any of the joints show signs of opening, red lead paint should be brushed well into the crevices ; this will protect the surfaces, which, otherwise, would be exposed. If this paint can be blown in by the aid of an air brush, it will be even more effective.

Do not permit wood wheels to become too dry ; they should be washed frequently with clean water, the mud being removed by a soft brush to avoid damage to the paint. Also damp sacks should be hung over the wheels if the wagon is left standing in a dry place for any lengthy period. The holes in the wheel bosses should be examined frequently, and, if necessary, tightened, care being taken alter doing so to replace the split pins. Wood wheels were at one time almost universally employed on steam wagons, and are still' often used for these, in conjunction with steel tires, as they give more resilience and have better shock-absorbing qualities than cast-steel wheels. It is well, however, not to expect too much in this direction, and care should be taken when driving over setts or over very rough surfaces.

If the steel tires stretch, as they are liable to do, the joints of the wheels may begin to open. In such cases the remedy is to cut the tires off, weld them to a slightly smaller diameter, and shrink them into position again.

Particular care should be taken with the wood wheels employed on some trailers which were originally intended for horse draught but, are now being used in eenjunction.with motor vehicles. The wheels are generally unsuitable for the higher speeds, and must be constantly watched.

246.—Adjusting the Magneto Drive on the Thornycroft.

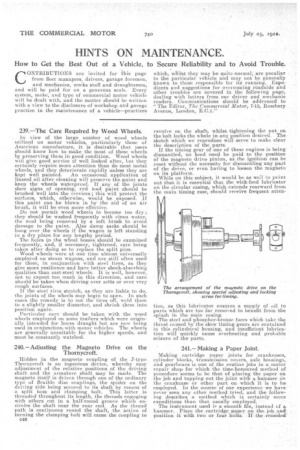

Hidden in the magneto coupling of the J-type Thornycroft is an ingenious device, whereby easy adjustment of the relative positions of the driving shaft and the armature shaft may be made. The magneto itself is driven through one of the ordinary type of flexible disc couplings, the spider on the driving side being •secured to its shaft by means of a split boss and clamping bolt. This latter is threaded throughout its length, the threads engaging with others cut in a half-round groove which encireles.the shaft near the rear end. As the thread path is continuous round the shaft, the action of turning the clamping bolt will cause the coupling to

0413 revolve on the shaft, whilst tightening the nut on the bolt locks the whole in any position desired, The sketch which we reproduce will serve to make clear the description of the parts. If the timing gear of one of these engines is being dismantled, no heed need be paid to the position of the magneto drive pinion, as the ignition can be reset without the necessity for dismantling any part of the drive, or even having to loosen the magneto on its platform. While on this subject, it would be as well to point out that it is essential that the wick-feed lubricator on the circular easing, which extends rearward from the main timing case, should receive frequent atteu tion, as this lubricator ensures a supply of oil to parts which are too far removed to benefit from the splash in the main casing.

The steel and phosphor-bronze faces which take the thrust caused by the skew timing gears are contained in this cylindrical housing, and insufficient lubrication will quickly cause overheating and probable seizure of the parts.

241.— Making a Paper Joint.

Making cartridge paper joints for crankcases, cylinder blocks, transmission covers, axle housings, and gearboxes is one of the routine jobs in a motor repair shop for which the time-honoured method of procedure seems to be that of placing the paper on the job and tapping out the joint with a, hammer on the crankcase Qs. other part on which it is to be employed. In the course of our experience we have never seen any other method tried, and the following describes a method which is certainly mere expeditious than that usually employed. •

The instrument used is a smooth file, instead ef a hammer. Place the cartridge paper on the jilt) and position it with two or four bolts. If -the -rounded

end of a bolt of larger diameter than those in use is pressed hard down and turned on the holes, with the paper interposed, clean-cut full-sized holes can be made for the positioning bolts, and all bolt-holes for the joint may be made in this manner. (The ball face of the hammer will do equally well, but pressing, instead of tapping,. is recommended as making a better job.)

Haying placed the paper in position, press your thumb or the file handle along the edges to be cut, so that an impression is left on the paper, and, following this impression simply use your file as if you were bevelling or chamfering the edges of the crankcase. A good firm stroke is sufficient to cut through the paper. It will be found that a very neat and clean-cut joint remains when the -file ha,s gone over the edges of the surface on which the joint is to fit.