PROGRESS IN GAS PRODUCER DESIGN.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

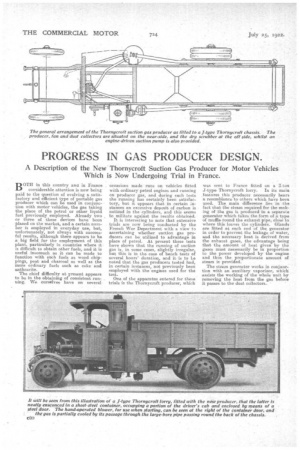

A Description of the New Thornycroft Suction Gas Producer for Motor Vehicles Which is Now Undergoing Trial in France.

BOTH in this country and in France considerable attention is now being paid to the question of evolving a satisfactory and efficient type of portable gas producer which can be used in conjunction with motor vehicles, the gas taking the place of the petrol or other liquid fuel previously employed. Already two or three of these devices have been placed on the market, and a certain number is employed in everyday use, but, unfortunately, not always with successful results, although there appears to be a big field for the employment of this plant, particularly in countries where it is difficult to obtain other fuels, and it is useful insomuch as it can be made to function with such fuels as wood chippings, peat and charcoal as well as the more ordinary fuels such as coke and anthracite.

The chief difficulty at present appears to be in the obtaining of consistent running, We ourselves have on several occasions made runs on vehicles fitted with ordinary petrol engines and running on producer gas, and during such tests the running has certainly been satisfactory, but it appears that in certain instances an excessive deposit of carbon is noticed in the cylinders, and this seems lo militate against the results obtained. It is interesting to note that extensive trials are now being conducted by the French War Department with a view to ascertaining whether suction gas producers can be utilized to advantage in place of petrol. At present these tests have shown that the running of suction gas is in some cases, slightly irregular, hut this is in the case of bench tests of several hours' duration, and it is to Le noted that the gas producers tested had, in certain instances, not previously been employed with the engines used for the test.

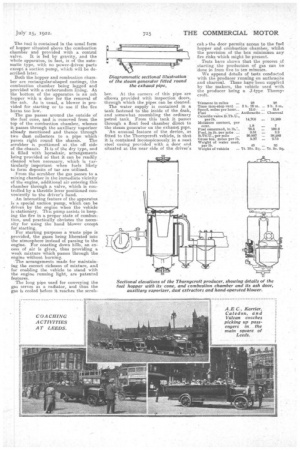

One of the apparatus entered for these trials is the Thornycroft producer, which was sent to France fitted an a 3-ton J-type Thornycroft lorry. In its main features this producer necessarily bears a resemblance to others which have been used. The main difference lies in the fact that the steam required for the making of the gas is produced in a separate generator which takes the form of a typo of muffle round the exhaust pipe, close to where this leaves the cylinders. Glands are fitted at each end of the generator in order to prevent the leakage of water, and the necessary heat is derived from the exhaust gases, the advantage being that the amount of heat given by the gases must necessarily be in proportion to the power developed by the engine and thus the proportionate amount of steam is provided.

The steam generator works in conjunction with an auxiliary vaporizer, which assists the working of the whole unit by removing the heat from the gas before it passes to the dust collectors. The tuel is contained in the usual form of hopper situated above the combustion chamber and provided with a control valve. It is fed by gravity, and the whole apparatus, in fact, is of the automatic type, with no power-ciriven parts except a suction pump, which will be described later.

Both the hopper and combustion chamber are rectangular-shaped castings, the combustion chamber being lagged and provided with a carborundum lining. At the bottom of the apparatus is an ash hopper with a door for the removal of the ash. As is usual, a blower is provided for starting or to use if the fire burns too low.

The gas passes around the outside of the fuel cone, and is .removed from the top of the combustion chamber, whence it passes through the auxiliary vaporizer already mentioned and thence through two dust collectors to a pipe which, passes right round the chassis. The scrubber is positioned at ..the off side of the chassis. It is of the dry type, and is filled with horsehair, arrangements being provided so that it can be readily cleaned when necessary, which is K-articularly important when fuels likely to form deposits of tar are utilized.

From the scrubber the gas passes to a mixing chamber in the immediate vicinity of the engine, additional air entering this chamber through a valve, which is controlled by a throttle lever positioned conveniently to the driver's hand.

An interesting feature of the apparatus is a special suction pump, which can be driven by the engine when the vehicle is statienary. This pump assists in keeping the fire in a proper state of conibus,. tiou, and practically obviates the necessity for using the hand blower except for starting.

For starting purposes a waste pipe is provided, the gases being liberated into the atmosphere instead of passing to the engine. For coasting down hills, an excess of air is given, thus providing a weak mixture which passes through the engine without burning.

The arrangements made for maintaining the correct richness of mixture, and for enabling the vehicle to stand with the engine running light, are patented features.

The long pipe used for conveying the gas serve.s as a radiator, and thus the gas is cooled before it reaches the scrub betAt the corners of this pipe are elbows provided with inspection doors, through which the pipes can be cleaned.

The water supply is contained m a tank fastened to the inside of the dash, and somewhat resembling the ordinary petrol tank. From this tank it passes through a float feed chamber. direct to the steam generator on the exhaust pipe.

An unusual feature of the device, as fitted to the Thornycroft vehicle, is that it is contained inconspicuously, in a neat steel casing provided with a door and situated at the near side of the driver's

cab a the door permits access to the fuel hopper and combustion chamber, whilst the prevision of the box minimizes any fire risks which might be present.

Tests have shown that, the process of starting the production of gas can be done in from five to ten minutes,

We append details of tests conducted with the producer running on anthracite and charcoal. These have been supplied by the makers, the vehicle used with the producer being a J-type Thornycroft