THAT CONDOR

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

• One outfit already preparing itself to take advantage of the new trailer length regulations is Condor International, based at Penarth near Cardiff.

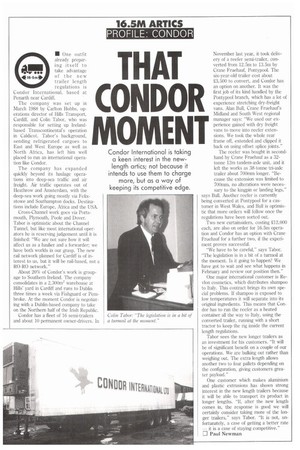

The company was set up in March 1988 by Carlton Hobbs, operations director of Hills Transport, Cardiff, and Cohn Tabor, who was responsible for setting up Irelandbased Transcontinental's operation in Caldicot. Tabor's background, sending refrigerated cargoes to East and West Europe as well as North Africa, has left him well placed to run an international operation like Condor.

The company has expanded quickly beyond its haulage operations into deep-sea traffic and air freight. Air traffic operates out of Heathrow and Amsterdam, with the deep-sea work going mostly via Felixstowe and Southampton docks. Destinations include Europe, Africa and the USA.

Cross-Channel work goes via Portsmouth, Plymouth, Poole and Dover. Tabor is optimistic about the Channel Tunnel, but like most international operators he is reserving judgement until it is finished: "We are not sure how it will affect us as a haulier and a forwarder; we have both worlds in our grasp. The new rail network planned for Cardiff is of interest to us, but it will he rail-based, not a RO-RO network."

About 20% of Condor's work is groupage to Southern Ireland. The company consolidates in a 2,300m2 warehouse at Hills' yard in Cardiff and runs to Dublin three times a week via Fishguard or Pembroke. At the moment Condor is negotiating with a Dublin-based company to take on the Northern half of the Irish Republic.

Condor has a fleet of 16 semi-trailers and about 10 permanent owner-drivers. In November last year, it took delivery of a reefer semi-trailer, converted from 12.5m to 13.5m by Crane Fruehauf, Pontypool. The six-year-old trailer cost about 2,500 to convert, and Condor has an option on another. It was the first job of its kind handled by the Pontypool branch, which has a lot of experience stretching dry-freight vans. Alan Bull, Crane Fruehauf's Midland and South West regional manager says: "We used our experience gained with dry freight vans to move into reefer extensions. We took the whole rear frame off, extended and clipped it back on using offset splice joints."

The reefer was bought in secondhand by Crane Fruehauf as a 32tonne 12m tandem-axle unit, and it left the works as 38-tonne tri-axle trailer about 700mm longer. "Because the extension was limited to 700mm, no alterations were necessary to the kingpin or landing legs," says Bull. Another reefer is currently being converted at Pontypool for a customer in West Wales, and Bull is optimistic that more orders will follow once the regulations have been sorted out.

Two new curtainsiders, costing £12,000 each, are also on order for 16.5m operation and Condor has an option with Crane Fruehauf for a further two, if the experiment proves successful.

"We have to be careful," says Tabor. "The legislation is in a bit of a turmoil at the moment. Is it going to happen? We have got to wait and see what happens in February and review our position then."

One major international customer is Revlon cosmetics, which distributes shampoo to Italy. This contract brings its own special problems. If shampoo is exposed to low temperatures it will separate into its original ingredients. This means that Condor has to run the reefer as a heated container all the way to Italy, using the converted trailer, running with a short tractor to keep the rig inside the current length regulations.

Tabor sees the new longer trailers as an investment for his customers. "It will be of significant benefit on a couple of our operations. We are bulking out rather than weighing out. The extra length allows another two to four pallets depending on the configuration, giving customers greater payload."

One customer which makes aluminium and plastic extrusions has shown strong interest in the new length trailers because it will be able to transport its product in longer lengths. "If, after the new length comes in, the response is good we will certainly consider taking more of the longer trailers," says Tabor. "It is not, unfortunately, a case of getting a better rate — it is a case of staying competitive." El Paul Newman