A SYSTEM FOR RECLAIMING USED OIL,

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

Waste Which Should be Avoided. Salving Emulsified Oil from Steam Wagons. The Treatment of Lubricant from Petrol Engines'.

IN a previous article, which dealt with the re-purifying of used oil, we pointed out how important it is for all who wish to study methods for improving transport economy to consider this subject, and that the original theory that oil permanently loses its lubricating properties through the breaking down of its constituent molecules is no longer upheld by facts, as by proper treatment a used oil may regain practically all its original characteristics. That at the moment a vast amount of oil is wasted cannot be denied by any user of mechanical transport vehicles ; in fact, one of the greatest difficulties facing those in charge of large fleets is how to dispose, of this old oil, which is contaminated by dirt, carbon in particles and in colloidal form, metal worn from the working parts and diluents from the fuel.

In this connection our attention has been drawn to a system of purification which is being used to an increasing extent in this country. It is known as the De Laval and is being marketed by Alfa-Laval Co., Ltd., Alfa-Laval House, 34, Grosvenor Road, &W.1. No references to this system have previously been made in a motor journal published in this country, and it should therefore be of particular interest to our readers,

The De Laval purifiers are all of the centrifugal type, some being quite simple. where it is required to remove only the impurities other than the fuel diluents, whilst those plants which effect complete purification are far more elaborate, and of one of these we give a diagram.

In the case of oil from steam engines this can be heated to 150 degrees F. and passed through the centrifugal purifier ; if the oil be in a complete state of emulsion it may be necessary to raise

c26

the temperature to 200 degrees F.,. which will bring it out of emulsification, and if any difficulty be found in obtain lug this effect a little salt may be added, which makes the water constituent "rather heavier. Such a process is extremely simple, and differs in many respects from some of the troubles encountered in the case of the internalcombustion engine, for here there are two additional substances to be removed —to wit, carbon and the diluents from the fuel. Actually, most concerns in England employing the De Laval system are content to heat up the oil to a temperature of, say, 180 degrees F. and then to pass it through the ordinary standard purifier.

Some users employ the recovered oil just as it is, others utilize 50 per cent. of recovered oil to 50 per cent, of new, and by letting the new oil be of a higher specific gravity the resulting mixture can be brought to the same specific gravity as the original oil.

Li the case of the carbon, this, as we have previously mentioned, is in two forms, comparatively large particles and colloidal carbon. Straightforward contrifngiug will remove the large carbon and the dirt, but has no effect on the colloidal carbon, and if a start be made with really dirty oil the centrifuged oil may be almost as dark in appearance as the dirty oil. It is claimed that when in this condition it is quite satisfactory to employ it for the engines of motor vehicles, as colloidal carbon has no illeffects, and some authorities claim that it actually improves the lubricating properties of the oil. However, in many cases oil is judged by its looks, and many a fleet engineer would look askance at oil discoloured in this manner.

To bring the repurified oil back to as near the original appearance as possible, the company has evolved certain decarbonizing agents in the form of powder. There are six of these, varying in their

Constituents and qualities, as it has been founi that certain oils respond only to certain powders. Their effect is to coagulate the colloidal carbon, thereby enabling it to be removed by centrifugal means.

Before supplying a potential user with a reclaiming plant the company likes to test the oils employed, so that success can be ensured by providing the correct treatment.

Not all the diluents are removed by these methods, and the viscosity of the cleaning oil may be slightly lower than that of the original oil; but this is a matter of little importance; because even if a start be made with a fresh oil in the engine the viscosity will return to the lower figure after a few hours of running, as there is a certain point at which a condition known as saturation

occurs. This is not really a correct term, but it will suffice. It is actually the point at which an oil refuses to take any more fuel diluent,. this probably being partly due to the effect of working temperatures.

There is another problem in cleansing which should also be of great interest, particularly to garage proprietors. This is the purifying of the paraffin used for washing oily and dirty parts. By centrifuging dirty paraffin all the dirt can be extracted, and the paraffin can continue to be employed for cleansing purposes. In fact, it can be put through the purifier a dozen times or so, but there is a limit, as after being used on many occasions the paraffin becomes saturated with oil and then loses its oilcleaning properties.

Reverting to the cleansing of lubricating oil, the usual quantity of decarbonizing powder is 1 lb. to 10 gallons of oil, the powder being .mixed with 10 gallons of water before employment. If the oil be really filthy a stronger solution will be required, but the price of the powder being about 6d. per lb., this does not add materially to the cost of purification.

Excluding the first cost and depreciation, but including labour and the cost of heating, the purifying of lubricating oil should certainly not be more than 3d. per. gallon. Including interest and depreciation, this figure is about doubled. The company is not satisfied with any yield of reclaimed oil under 90 per cent, of the dirty oil employed. The actual yield is usually nearer 98 per cent.

The main feature of the De Lewd centrifugal purifier is, of course, the bowl, in which revolves a number of conical vanes at a speed of approximately 6,000 r.p.m.

In operation, water is first run into the pan above the bowl, while the vanes are revolving. The water travels down between the vanes and forms what may be termed a water wall around the inside of the bowl, this wall extending a short distance up the vanes, the distance depending upon the size of the orifice in a special washer fitted at the upper part or the bowl. Any excess of water travels upwards and out of the lowest of three spouts which are provided. Dirty oil can then be allowed to ran into the pan and, entering between the vanes, is whirled at high speed, the dirt, carbon, etc., being flung out into the wall of water. As more °ills added the cleaned oil flows upwards and ont of the central spout of the purifier. If any oil begins to flow from the uppermost spout, this is an indication that the machine requires cleaning, a process which takes but a few minutes, it being necessary only to remove the coned vanes and to Adpe the dirt from the sides of the howl.

Each machine is driven by an electric motor through a belt and spiral gearing.

The prices range from 135 for a machine to ,reat 10 gallons per hour, this includiag the electric motor. This price refers only to the centrifuging machine, but for the removal of colloidal carbon special washing-tank equipment which can also be provided by the company, is required.

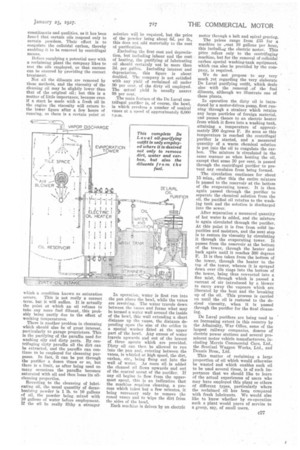

We do not propose to say very much yet regarding the very elaborate De Laval purifying outfit, which deals also with the removal .of the fuel diluents, although we illustrate one of these plants.

In operation the dirty oil is introduced by a motor-driven pump, first running through a strainer which retains any large particles of foreign material, and passes thence to an electric heater from which it flows into a washing tank, attaining a temperature of approximately 200 degrees F. So soon as this temperature is reached the centrifugal purifier is started, and a measured quantity of a warm chemical solution is put into the oil to coagulate the carbon. The mixture is circulated in the same manner as when heating the oil, except that some 30 per cent, is passed through the centrifugal purifier to prevent any emulsion from being formed.

The circulation continues for about 15 mina., after this the entire mixture is passed to the reservoir at the bottom of the evaporating tower. It is then again passed through the purifier to separate the chemical solution from the oil, the purified oil retutms to the washlug tank and the solution is discharged into the sewer.

After separation a measured quantity of hot water Is added, and the mixture is again circulated through the purifier. At this point it is free from solid impurities and moisture, and the next step is to restore its viscosity by circulating it through the evaporating tower. It passes from the reservoir at the bottom of the tower, through the heater and back again until it reaches 300 degrees F. It is then taken from the bottom of the tower, through the heater to the top of the tower, whence it is sprayed down over tile rings into the bottom of the tower, being thus converted into a fine mist, through which is passed a current of air introduced by a blower to carry away the vapours which are liberated by the heat and the breaking up of the oil. This process is carried on until the oil is restored to the desired viscosity, when it is passed through the purifier for the final cleansing.

De Laval purifiers are being used to an increasing extent in this country by the Admiralty, War Office, some of the largest railway companies, dozens of electric power stations and several prominent motor vehicle manufacturers, including Morris Commercial Cars, Ltd., the Sentinel Waggon Works, Ltd., :Ind Dennis Bros., Ltd.

This matter of reclaiming a large proportion of oil which would otherwise be wasted and which enables such oil to be used several times, is of such importance that we should like to learn of the actual experiences of users who may have employed this plant or others of different types, particularly where the reclaimed oil has been compared with fresh lubricants. We would also like to know whether by co-operation such a plant would prove of service to a group, say, of small users.