UALITY Foden is best known for the seemingly endless range

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

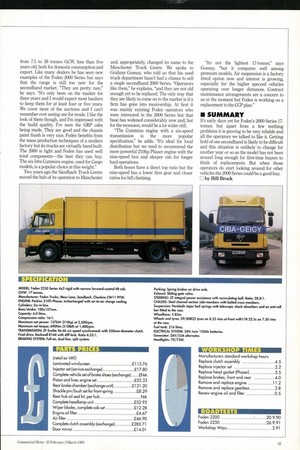

of options it offers. For the past couple of years that service has been available to operators of 17-tonners, courtesy of the 2000 Series. We asked operators and dealers how it's shaping up. 0urroad tests of both the Foden 2000 odels showed little difference in fuel economy between the Perkins Phaser 210-powered 2250 and the Cummins 6BTA 180-engined 2200. The 5.9-litre Cummins B Series fared well on motorway work but the more powerful and torquey 6.0-litre Perkins Phaser engine did better on the longer A-road section of CM's middlewieght route. So the Phaser just had the edge overall with figures of 22.4lit/100km (12.6mpg) compared with 22.761it/100km (12.41mpg) for the B Series. Both 17-tonners were equipped with a direct top gear but the higher final drive ratio of our Cummins-powered 2200 identified insufficient torque backup to maintain drive at below 64km/h (40mph) without resorting to a lower gear There is a choice of differential ratios to suit various operations A 7.1-tonne front axle contributes to the loading tolerance of 600kg; payload potential is slightly better with the B Series engine .Our Cummins-engined vehicle was specified with a nine-speed 6109 Eaton range-change box. It can't be rushed but its easy to use. The six widely spaced cogs of the ZF unit specified with the Perkins encouraged the driver to hang on to gears especially on the hills. Lever movements were heavy and slow but few 17tonners will out-accelerate it.

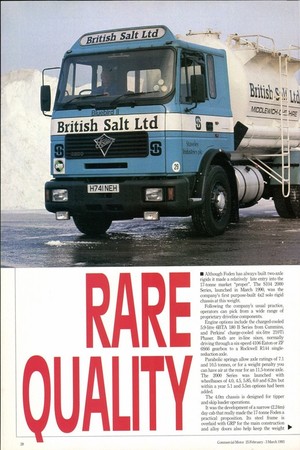

F1F1oden's image as a lightweight truck builder took a bit of a knock at 17 tonnes as 2200's body/payload allowance of 2.12 tonnes is only average. But the light, rust-free GRP cab's clear back panel enables the body to be fitted very close leaving a small gap for tilt clearance. The cab is well insulated although not as quiet inside as the ERF or Mercedes-Benz 1 7-tonners. 1 The seat and steering column adjust to fit most sizes and shapes of drivers Only the gear lever remains a hindrance to cross-cab movement. Parabolic springs all round, with antiroll bar at the rear, gave a fairly soft but \ level ride. Air suspension is available to \ ease the ride for delicate loads: it adds only ' 123kg to the unladen weight. • Although Foden has always built two-axle rigids it made a relatively late entry into the 17-tonne market "proper". The S104 2000 Series, launched in March 1990, was the company's first purpose-built 4x2 solo rigid chassis at this weight.

Following the company's usual practice, operators can pick from a wide range of proprietary driveline components.

Engine options include the charged-cooled 5.9-litre 6BTA 180 B Series from Cummins, and Perkins' charge-cooled six-litre 210Ti Phaser. Both are in-line sixes, normally driving through a six-speed 4106 Eaton or ZF 6S66 gearbox to a Rockwell R144 _ _ gearbox _ _ _ Rockwell _ _ _ _ _ _ _ singlereduction axle.

Parabolic springs allow axle ratings of 7.1 and 10.5 tonnes, or for a weight penalty you can have air at the rear for an 11.5-tonne axle. The 2000 Series was launched with wheelbases of 4.0, 4.5, 5.85, 6.0 and 6.2m but within a year 5.1 and 5.5m options had been added.

The 4.0m chassis is designed for tipper and skip loader operations.

It was the development of a narrow (2.24m) day cab that really made the 17-tonne Foden a practical proposition. Its steel frame is overlaid with GRP for the main construction and alloy doors also help keep the weight down to 90kg less than Foden's full width GRP cab.

• EVOLUTION The 2000 Series is a relative newcomer and was introduced with Foden's usual wide range of options. With the choice of air suspension rated at 11.5 tonnes, alloy wheels, an AD6S air dryer, two engines and three transmissions there has been little reason to make further changes!

• OPERATORS British Salt, part of the international Staveley Industries group, has been supplying the health and food industries from its Middlewich plant since 1960. Sandbach, just three miles down the road, is the home of two vehicle manufacturers, but transport engineer Terry Edwards told us: "Our transport fleet of 23 vehicles is 100% Foden. The local agent is just along the road from us and we have an arrangement to draw spares as and when we need them up to 11.00pm. Our workshops operate a day and a night shift.

"The non-corrosive element in the cab's construction is very important to us," says Edwards. "A steel cab doesn't last any time at all with our product. We keep our vehicles for about eight years. If we used steel cabs they would need constant attention throughout their lives but we hardly ever touch Foden's composite cab. We have two 2000 Series 17tormers which we like to think are quality vehicles that will last a lot longer than we will keep them. The chassis are shot blasted and protected with Belzona, a ceramic paint, when the vehicles are new. A local firm does it for about £600 and it's worth it. The treatment is guaranteed for five years and we don't have any problems afterwards," he adds. "The aluminium air discharge bulk tanks, built by Metalair with stainless-steel fittings and a Drum 550 air compressor will have been fitted to two chassis and are good for 16 or 17 years before we replace them.

"We bought the 2000 Series to give us easier access to difficult delivery sites," Edwards explains. "Both vehicles have sleeper cabs and cover over 110,000km a year with a payload of about 10.5 tonnes. We don't have the luxury of return loads so we only run fully laden for 50% of the time. The Cummins 180 is powerful enough for 17 tonnes and it's quite economical. We get around 14.5mpg which is inclusive of blowing time. If we can't get close to the delivery point and have to use long lengths of hoses,discharge can take up to an hour at a time."

British Salt's vehicles get a full service every 26 working days which includes oil and filter change. At about 160,000km (100,000 miles) a water pump had to be replaced, which was covered by warranty. Pirelli tyres were specified originally and have been replaced with more of the same. There has been no wear problem with tyres or brakes and in general the service record has been uneventful.

Edwards sells his old Fodens off to local operators and doesn't anticipate any difficulty getting rid of the 2000 Series when their time comes.

Ciba Agriculture runs eight vehicles out of its plant at Whittlesford, where it produces animal health, crop protection and veterinary products. Most are 24-tonne Volvo FL7s with a single Foden 3000 Series, all used for larger volume deliveries, but the company chose a Foden 2000 Series to look after High Street deliveries of its Pet Care product range.

Ciba used to maximise vehicle use with demount systems, loading one at base while the vehicle made its deliveries with another. Now forklift pallet loading is so quick that turnround time is no longer a problem, and with a conventional body the full 10.5-tonne payload capacity can be used. The rigid Boalloy Slide-a-Side bodywork combines full side access with security.

Assistant distribution manager John Mogg involved his drivers in the choice of vehicle from the outset: "They tried several different trucks and the Foden came out best overall in their estimation. It's light and it comes with a sleeper cab which we have fitted with a night heater and a phone. Foden's fixed-height roof spoiler matches the body height of our 17tonner," he adds, "but it looks less efficient with the taller bodied 3000 Series.

Every Ciba vehicle has a dedicated driver who are encouraged to maintain the company's image. Ciba Agriculture is the only division within the company to operate its own vehicles. "It allows us much closer control," says Mogg. "Some of the products we deliver are chemicals, but all of our drivers are HazChem trained but most don't fall within the scope of the PGR regulations, and every vehicle carries a fire extinguisher and Master Trem card and safety data sheet for all products on board.

"We had a few minor problems," he says, "mainly to do with the accelerator connections. The cable came adrift once and another time broke completely. The call out time was abysmal—I suppose we are used to the service from Volvo's bigger dealer network. The driver had to wait two hours the first time and an hour and a half to fix it, and it took three hours to get it back on the road the second time.

"After just seven months the clutch and housing was replaced under warranty," adds Mogg. "That was a day and a half off the road. Service from our local dealer is normally very good but he had to wait for a part this time. All servicing is done at the weekends under a contract maintenance deal; we keep to the manufacturer's recommendations. We utilise the wagons as much as we can. There are some opportunities for back loads with the 24tonners but the same opportunities are not there for the 17 tonrier."

We asked if Ciba will buy another. After a little thought Mogg replied: "Well we bought two Volvos last year which we will keep for four years, and Volvo give a three-year warranty on major parts and labour. It means we can have a preventative maintenance contract which works out cheaper. On the 24-tonners we save £169 per month per vehicle—that's more than £8,000 over the contract term."

Bligh Boards, a sheet materials importer, supplies building sites, joinery shops and builders merchants across the South of England from its headquarters in Stood and depot at Salisbury. We spoke to transport manager David Goulden, who operates three LGVs out of the West County depot: a Leyland Daf Roadrunner, a 4x2 3000 Series drawbar at 32 tonnes and a Foden 2000 Series rigid 17-tonner with a curtain-sided body.

"The 2000 Series operates within a 60-mile radius," he says. "It goes out with a full load and makes between 15 to 18 drops each run, covering up to 1,000km a week. Most of the load is palletised and we use a fork lift to put it on the truck. There's a clear length of platform at the rear where we can put awkward sized loads, but most of the boards are 8x4 and we get them under cover." When Bligh / Boards was / looking for a 17tonner almost three _ years ago the company approached the Mercedes-Benz dealer at Andover, "but as we only wanted the one they weren't very interested," says Goulden. "Our main options were Foden and ERF but only Foden could offer us overnight servicing at the time. That and the price clinched it. It's a contract-maintenance deal for five years under the Commercial Care Plan: we change our vehicles after that long anyway. They become less cost-effective the older they get. We can't afford unscheduled time off the road as ours is a next-day delivery service. Nothing major has gone wrong with the 2000 Series yet.

"We specified the 6BTA Cummins engine because we know it's reliable from previous experience with it in other vehicles we have had," he adds. "The payload is 10.5 tonnes but with a diminishing load we get 50% utilisation and fuel consumption of 13.5mpg. Tyre life is very good. The fronts were changed at 120,0001un and the rears are still original at 160,000km. We have had a couple of small warranty claims with the brakes, and some bolts in the bodywork came loose. All warranty claims have become harder to get through CCP since it withdrew from the truck market.

"We like the cab," says Goulden. "It's roomy, it's not dark like some and the instruments are good. The park brake lever is a bit low down but the gearbox (we've got a nine-speed), is very nice to use once it's warmed up. The narrow cab means that the mirror support arms need to be long to see down the side of the body. They could be set a bit wider but the cab's GRP construction is fine. We will certainly buy another."

DEALERS Chris Hodge rates among the largest used truck dealers in the South of England. He keeps a stock of about 100 vehicles, ranging from 7.5 to 38 tonnes GCW, less than five years old, both for domestic consumption and export. Like many dealers he has seen new examples of the Foden 2000 Series but says that the range is still too new for the secondhand market. "They are pretty rare," he says. "It's only been on the market for three years and I would expect most hauliers to keep them for at least four or five years. We cover most of the auctions and I can't remember ever seeing one for resale. I like the look of them though, and I'm impressed with the build quality. I've seen the GRP cabs being made. They are good and the chassis paint finish is very nice. Foden benefits from the mass production techniques of a modern factory but its trucks are virtually hand built. The 2000 is light and Foden has used well tried components—the best they can buy. The six-litre Cummins engine, used for Cargo models, is a popular choice at this weight."

Two years ago the Sandbach Truck Centre moved the hub of its operation to Manchester and, appropriately, changed its name to the Manchester Truck Centre. We spoke to Graham Gosnay, who told us that his used truck department hasn't had a chance to sell a single secondhand 2000 Series. "Operators like them," he explains, "and they are not old enough yet to be replaced. The only way that they are likely to come on to the market is if a firm has gone into receivership. At first it was mainly existing Foden operators who were interested in the 2000 Series but that base has widened considerably now and, but for the recession, would be a lot wider still.

"The Cummins engine with a six-speed transmission is the more popular specification," he adds. "It's ideal for local distribution but we tend to recommend the more powerful 210hp Phaser engine with the nine-speed box and sleeper cab for longer haul operations.

Both boxes have a direct top ratio but the nine-speed has a lower first gear and closer ratios for hill climbing. "Its not the lightest 17-tonner," says Gosnay, "but it compares well among premium models. Air suspension is a factory fitted option now and interest is growing, especially for the higher specced vehicles operating over longer distances. Contract maintenance arrangements are a concern to us at the moment but Foden is working on a replacement to the CCP plan."

• SUMMARY It's early days yet for Foden's 2000 Series 17tonner, but apart from a few teething problems it is proving to be very reliable and all the operators we talked to like it. Getting hold of one secondhand is likely to be difficult and this situation is unlikely to change for another year or so as the model has not been around long enough for first-time buyers to think of replacements. But when those operators do start looking around for other vehicles the 2000 Series could be a good buy. 7 by Bill Brock