Modern aids for your business =...ffi

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

EFFICIENT traffic planning is playing an increasing role in the search for improved pro ductivity within the field of marketing, distribution and road transport. Without it the best performance cannot be obtained from drivers and vehicles, and customers will not get the service they are seeking.

kir this situation to be achieved it is necessary to esteblis.t certain measures of work con ent and these include

•

Fl

lanning the size of the vehicle fleet.

• Planning the journey using numbers of deliveries, tonnage and mileage as targets measur d against the time required to complete the journey bearing in ind the density of traffic, acc ss to unloading bays, wea her, etc.

• The introduction of incentives to drivers.

New operators in particular mut learn that in road haulage, tra sport availability and cap city, if not used imrrediately, can be lost for eve S ccessful distribution will be achieved only if an ideal veni le fleet and correct delivery sch dule can be operated. Ho ever, this is not always pra tical and a compromise mus be reached.

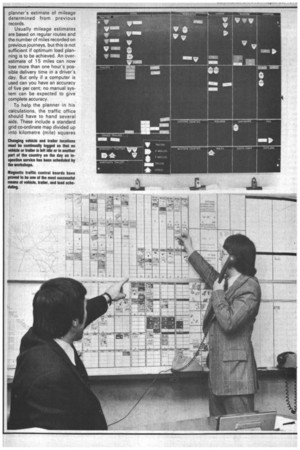

T chnical aids such as compute route scheduling are now freq ently used in assisting in traffic planning, and these will bec me more widely used in cert in types of delivery work. But ertain qualities such as initiatilze, flexibility, hard work, discipline and common sense must not be disregarded no matt r what modern aids are bein used.

The computer is not new and will not make a traffic planner redu dant. However, the per

sonrri

esponsible for traffic planning will have to have a far broader knowledge of distribution than before. He will need: • A sound working knowledge of a given area.

• Inventiveness and ability to combine deliveries and tonnage miles, with miles run to best advantage. • Knowledge of current legal requirements for drivers, vehicles and records.

• The ability to gain the confidence of drivers, whose productivity can depend on the acceptance of the planning skill of those in charge of their dayto-day working.

• Knowledge of the cost factors under transport control and .the role they play in the profitability of a transport company.

Load or traffic planning is not just the day-to-day business of collating loads but includes the problem of fully using all resources available in a system. Because traffic planning can be the largest variable cost factor in the distribution of a product it is true that the better the fleet the easier will be the day-to-day planning.

When a company is wholly engaged in distribution work on behalf of a number of clients or when a manufacturer carries out its own distribution there is a general preference to employ its own vehicles because, operated efficiently, they should be cheaper, particularly for local deliveries, than hired-in vehicles.

Also they will be more flexible and direct control may be exerted over the combined activities. Placing the last link in the distribution chain in the hands of hired-in transport can be unsuitable especially where the weekly tonnage fluctuates due to seasonal changes in demand.

It is often cheaper to hire on a casual basis for peaks rather than increase the basic fleet and have vehicles, trailers and men standing idle during slack periods.

There are many points to be considered when the fleet is being reviewed but in the majority of cases this has already been done and is outside the control. of the traffic department.

Once the basic routes have been determined, loads must be planned and allocated on a daily basis.

One popular method of sorting the orders is to use a pigeon-hole rack; it is beneficial

if the pigeon holes are allocated in a logical sequence so that they correspond with the geographical position of the delivery sections.

For example, orders for a sector in the north-east corner of the territory should be placed in the top right-hand pigeon-hole of the rack.

Each pigeon-hole label should include at least the sector reference, the town or district and the nominated delivery days.

Extra pigeon-holes should be available for bulk orders or special deliveries.

Before an order is received in the traffic department, it should have been checked and any special transport requirements noted so that it can be immediately inserted into the correct pigeon-hole for final marking-up in loads.

If possible, the sector reference should be marked against every location included on the schedule of nominated delivery days, so that the orders can be quickly placed into the right pigeon holes.

A nominated delivery day or planned day delivery is designed to co-ordinate as far as reasonably practical the requirements of a sales and production organisation and the transportation of a customer's order.

When placing the orders in the pigeon-holes, always insert face downwards so that when removed the pile is turned over, bringing the oldest orders to the top.

It will also help if a route card is placed in each pigeon hole to show, preferably in alphabetical order, the name of the town or city and road to which regular deliveries are made.

The route cards can also contain such information as difficult delivery points, shop opening hours, local holidays and any other information to assist the driver or traffic planner in his work. This type of information can be invaluable, particularly to drivers unfamiliar to the delivery area.

If possible, the driver should keep to the established route so that a vehicle may be quickly traced.

At a pre-determined time the loads can be made up from the orders in the rack. Where necessary, sectors may be combined or split into further sec

tions to produce an approximate vehicle load in terms of weight, deliveries and amount of work.

This load will then represent a certain amount of the driver's time which will probably have been determined by the load planner's -guesstimate"' based on previous experience. Then to this must be added the load

planner's estimate of mileage determined from previous records.

Usually mileage estimates are based on regular routes and the number of miles recorded on previous journeys, but this is not sufficient if optimum load planning is to be achieved. An overestimate of 15 miles can now lose more than one hour's possible delivery time in a driver's day. But only if a computer is used can you have an accuracy of five per cent; no manual system can be expected to give complete accuracy.

To help the planner in his calculations, the traffic office should have to hand several aids. These include a standard grid co-ordinate map divided up into kilometre (mile) squares lich covers the whole of the livery area.

A distance conversion chart Dunted beside the map is eful together with a list of

.ect road distances between jacent main towns and cities,

mpany depots and regular stomers. These will save a nsiderable amount of time.

Al st of the nearest motorway trances and exits from parti lar locations and a mileage :tor chart which takes into 3ourrt any indirect distance tween drop points are also eful.

For localised retail deliveries, my hauliers use an indirect leage factor of 0.5-0.7 miles, garded as being incurred lely by running from one drop another within any one locan.

The planner should now have tails of the deliveries, weight d distance for a journey and to is he must add other time owances applicable such as

anred or standard times or deliver) allowance for Ilection of cash or returned ,ods.

He will then be in a position adjust the load or schedule to the agreed standard working iy, nce he has completed the hed le, he will be ready to ss i to the production dept les dept or warehouse, as plic ble, for their action.

Th traffic planner must be le o measure the perfor anc of his department as well th I of the drivers and hid l s, otherwise he will have reference on which to make s or recommendations. therefore have to deternd then apply certain and operating rds.

se will also be required to te future planning of journeys and deliveries.

ust also be able to protailed information based

ndard timevalues as a or determining transport If individual product deroups. This can however problems where variable rop work is involved,

tart any form of work ement. the driver's day e divided into three parts: on and delivery time, time and depot or terime.

icle running time can be into four parts: city or work, suburban or tial areas, direct journey al running and trunk on between cities or terpoints using motorways carriageways.

study must also cover ang wi me )nd Th cilit hidl He ie d ''St sis sts ery use ultiTo easu ust lect nnin inal Ve vide wn side ru )e rat inal dua The

I.

distance and travelling time and include such things as traffic lights, congestion, parking, access to premises, road works as well as bad weather.

For example, when making deliveries to the retail grocery trade, average speeds can be in the region of 10mph, 15mph and 24mph for the first three forms of vehicle running time and 27-35mph when motorway running is involved between depot or terminal and customers premises, For other trades or industries, these can be increased or decreased, depending entirely on vehicle specification and goods carried.

It is possible with further analysis to show that according to the number of deliveries made, a pattern emerges as journey miles increase, town and suburban miles decrease as a proportion to the total miles run, in a distribution system where centres are mainly located near to the centres of population.

Selection and delivery times can be divided into four areas: basic standard time applicable to a delivery irrespective of the type of product or customer, selection of goods in the vehicle by the driver, delivery of goods into premises (this includes a percentage for assistance by customers' staff) and waiting for off-load assistance for heavy loads at engineering works, building sites etc.

The basic time for each delivery must include all aspects of time taken, regardless of the type or quantity of goods delivered, for instance leaving and entering the cab, opening and closing of warehouse doors, waiting at customers' premises for a loading bay to fall free, locating storekeepers, obtaining signatures, collecting returnable goods, pallets or containers etc.

It is important to keep this part of the basic time separate from the select and deliver time as this is only applicable to the actual number of deliveries. Where articulated vehicles are used, dropping and picking-up time as well as checking load and sheeting and roping must be taken into account.

The selection of goods by the driver may be easily determined and should not require any further adjustments. They can in fact be incorporated with the times for delivery into customers premises for assistance from customers staff.

This is not an insignificant part of delivery time. For example it can vary from 5 per cent for small deliveries of up to 10 cartons, to 80 per cent for deliveries of 100 cartons or more. Time must also be allowed where special lifting tackle is required.

Determination of an overall load will be the addition of the total basic time to the select and deliver time. The total basic time is determined by multiplying the actual number of delivery times by the basic time standard.

Terminal time usually takes into account the time spent on loading, routine tasks which in

clude checking the vehicle and documentationi,oaying in cash

collected etc. It is recommended that terminal time is divided into two parts so as not to allow time to any driver whose vehicle is loaded in his absence by depot or terminal staff.

Final load assessment can be determined from four separate areas: • Provisional load from the routine traffic office system.

• Provisional load passed to "add listoperator who will total individual standard time values for the -select and deliverparts of each order so giving a total select and delivery time for the load.

• Whilst the -select and de

liver" times are being add-listed the load planner will estimate the total mileage of the load using a formula based on a mixture of direct road mileage, grid co-ordinate distances and the indirect mileage factor for the number of deliveries on the total load.

• Standard times for select and deliver, running and terminal or depot work are now added together and the total work load adjusted by the removal or addition of deliveries so as to give a load as near to the planned standard day as possible.

It is important that once any new journey has been completed, the result of the schedule is studied to check on any miscalculations or other errors which can be corrected for the future.

Efficient traffic planning is becoming more and more critical for maximum utilisation of vehicles and drivers. Companies who will succeed in road distribution will be those who are able to make changes readily so controlling spiralling operating costs and yet not to the detriment of customer service.