EQUIPPING THE COMMERCIAL GARAGE.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

Appliances which can Easily be Made and Will Quickly Repay Their Cost. Hints on the Promotion of Efficiency.

ALTROUGH in most cases there has been a marked improvement in the equipment of garages where repair work is undertaken, there is still room for advancement and additions to tho outfit where overhauls and work of a more serious character are carried out. The makers of tools for this purpose have done much to provide the repair shop with suitable appliances, and there are many practical devices now on the market which reduce the cost of labour and produce better work.

The forthcoming exhibition of garage equipment, to be held simultaneously with the Commercial Vehicle Show, bids fair to bring forward many new improvements in this direction.

Owing to the fact that specialists are now catering for the production of certain component parts, there is hardly the need for the garage owner to put down a very costly plant, as there is always the difficulty of finding sufficient work for such a plant to make it a profitable investment. Operations such as gear-cutting and those entailing case-hardening, which necessitate grinding afterwards, will always be rather beyond the capacity of the ordinary repair ahop, owing to the heavy cost of a complete gearcutting and grinding outfit. Apart from these more serious operations, there are many suggestions for small improvements, and for certain useful appliances which a garage may make for itself in spare time, which may be welcomed.

The garage tools and appliances on the market are in most eases designed primarily for use with private cars, and sre often found to be of little use when applied to the heavier types of commercial motor. In all probability the makers of such appliances have not 3een a sufficiently large market to

warrant their designing specially heavy tools for the jobs, which are often necessary in the maintenance and repair of heavy commercial vehicles. As the use of commercial motors grows, however, in all probability the need for heavier tools will be recognized, and certain firms will set themselves out for their manufacture. In the meantime, however, garage engineers could often make some simple appliances which they would find of the greatest value when dealing with heavy jobs.

An Improved Type of Press.

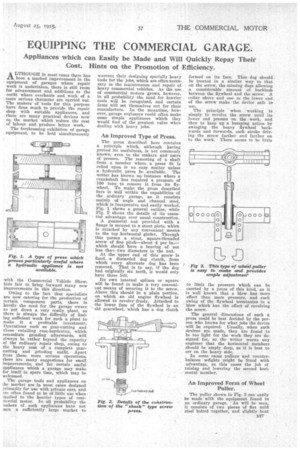

The press described here contains a principle which, although having proved its usefulness, is not commonly known, even to the makers and users of presses. The removing of a shaft from a member where a press fit is relied upon is no easy matter unless a hydraulic press be available. The writer has known an instance where a crankshaft has required a pressure of 100 tons to remove it from its flywheel. To make the press described here is well within the capabilities of the ordinary garage, as it consists mainly of angle and channel steel, which is inexpensive and easily worked. Pig. 1 shows a general outline, while Fig. 2 shows the details of its essential advantage over usual construction.

A gunmetal nut provided with a flange is secured to a stout plate, which is attached by any convenient means to the top horizontal girder. Through this passes a stout, square-threaded screw of fine pitch—about 4 per in.— which should have a bearing of not less than two diameters in the nut.

At the upper end of this screw is fixed a discarded dog clutch, from which every alternate dog has been removed. That is to say, if the dog had originally six teeth, it would only have three left.

Its own internal splines or square. will be found to make a very convenient means of securing it to the screw. Above this should be a plain portion, on which an old engine flywheel is allowed to revolve freely. Attached to the lower face of the flywheel is an ` old gearwheel, which has a dog clutch formed on its face. This dog should be treated in a similar way to that on the screw, the missing dogs allowing a considerable amount of backlash between the flywheel and the screw. A collar above and one al: the lower end of the screw make the device safe to use.

The principle when working is simply to revolve the screw until its lower end presses on the work, and then to keep up a bumping action by swinging the heavy flywheel backcards and forwards, each stroke driving the screw farther and farther on to the work. There seems to be little to limit the pressure which can be exerted by a press of this kind, as it is well known that a blow has more effect than mere pressure, and each swing of the flywheel terminates in a blow which has the effect of revolving the screw.

The general dimensions of such a press could be best decided by the person who knows for what jobs the device will be required. Usually, when such devices are made, they are found to be too light for the work they are designed for so the writer warns any engineer that the horizontal members should be amply deep, as it is best to err on the heavy side.

In some cases pulleys and counterbalance wcights might be fitted with advantage, as this eases the job of raising and lowering the second horizontal member.

An Improved Form of Wheel Puller.

The puller shown in Fig. 3 can easily be made. with the equipment found in an ordinary garage. As will be seen, it consists of two pieces of flat mild steel bolted together, and slightly bent

to receive the nut. For commercialvehicle work its proportions should be very ample.

Most users of pullers who have had to remove an obstinate wheel from a shaft where it has seized or rusted up have doubtless found that the ordinary puller will fail to have the effect for which it was designed. The puller shown here will be seen to have a hollow screw, which is the essential feature, in which it differs from the ordinary types. It is well known that pressure alone will often fail to start a stubborn ease of a tight wheel on a shaft, whilst, if a sharp blow could be given to the offending part while the pressure is maintained, a start can often be effected. With this object in view the screw is made hollow so that a punch "can be introduced and a blow given to the end of the shaft. If pressure be maintained by means of a wrench on the screw it will be found that, as each blow is given, the screw can be slightly turned.

The hollow screw affords a very good guide for the punch, which, of course, must not be too tight a fit.

Another useful rig is that shown in Fig. 4, which is for holding brake facings closely to their shoes, white holes are being drilled and rivets inserted. The writer had found this arrangement act more efficiently than moulds made especially for one type of brake, as the chain can accommodate itself to any variation in the thickness of the lining, whereas a rigid mould will not do so.

The cutting of metal plates and sheets is a job which sometimes gives a good deal of trouble with the ordinary type of shears. .

The machine shown in Figs. 5 and 6 will cut to A in. thickness. It can he used for straight or curved work, and can be lifted from its base and carried to a job so as to cut off a piece in place. It is handled by the Selson Engineering Co., Ltd., 85, Queen Victoria Street, London, E.C.4.

The emery wheel Is usually looked upon as a rough means of removing metal only, and, being "any man's tool," is usually sadly neglected. A small emery wheel mounted in a convenient position for use by fitters, and kept in really good order as regards the side of the wheel, will save ,much time, as, used with skill, it is more accurate and better than much filing.

A rest should be provided at right angles with the side of the wheel, and the wheel should be kept flat on its side by truing it up from time to time in a lathe with a Huntington trimmer held in a slide rest. A diamond is perhaps better, but it is not often found in an ordinary garage. For the fitting of keys, etc., such a wheel will be found of great value.

With regard to the garage lathe, the writer is of the opinion that the most suitable lathe for this purpose has yet to be designed. The points which would go to make an ideal garage lathe would occupy more space than is available in this article, so may be dealt with in a separate article later. With regard to the general arrangements of a repair shop, there is no need for the dirty benches and floors one generally finds in suc,h places. Dirt does not impress customers that their cars will be carefully handled, so it should be avoided so far as possible.

All benches should be covered with a stout plate of steel, sufficiently thick to prevent it from being dented by heavy articles. Such benches can be wiped clean after each job.

Much dirt can be avoided by having a more systematic plan for cleaning off

parts before they go on to the bench. Many cleaning baths are now on the market, but, failing these, if the parts to be cleaned are taken to a wash place and given a bath of paraffin to loosen the thick oil, they can be laid on the floor and if played upon with an ordinary cleaning jet of cold water at a goodpressure will be found to be perfectly cleaned.

This plan effects a great saving in rags, which are not only costly, but are difficult to dispose of, and are a danger if left about. In many repair shops the vices are still of the old-fashioned leg type instead of the modern quick-grip type. Deep drawers under benches should on no account be tolerated, as they mean loss of time in finding things. Shallow drawers: and plenty of them, are what is wanted. Racks should be provided over the benches with pegs to receive ball bearings while reassem

bling is in progress, as, if left lying on benches, they are sure to get filings in them. No lumber should be allowed to accumulate under benches, as small parts dropped from the bench may take a long time to find. All useless scrap and broken parts should be instantly sorted from that which is useful and got rid of. Much of it can be sold to scrap metal dealers.

In most repair shops a little more of the "place for everything and everything in its place" would be an improvement.

A humorist once remarked that this was the order of things in a certain workshop, the only drawback being that it was all the same place—the floor.