Tilts for piggybacking

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

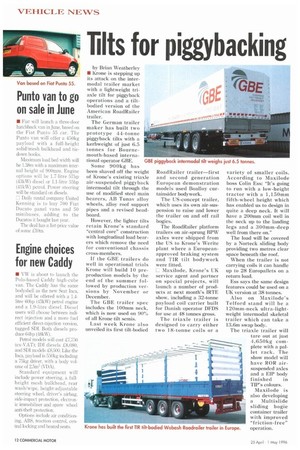

by Brian Weatherley • Krone is stepping up its attack on the intermodal trailer market with a lightweight triaxle tilt for piggyback operations and a tiltbodied version of the American RoadRailer trailer.

The German trailer maker has built two prototype 44-tonne piggyback tilts with a kerbweight of just 6.5 tonnes for Bournemouth-based international operator GF1E.

Some 900kg has been shaved off the weight of Krone's existing triaxle air-suspended piggyback intermodal tilt through the use of modified steel main bearers, AB Tunav alloy wheels, alloy roof support pipes and a revised headboard.

However, the lighter tilts retain Krone's standard "central core" construction with longitudinal load bearers which remove the need for conventional chassis cross-members.

If the GBE trailers do well in operational trials Krone will build 10 preproduction models by the end of the summer followed by production versions by November or December.

The GBE trailer spec includes the 100mm neck, which is now used on 90% of all Krone tilt semis.

Last week Krone also unveiled its first tilt-bodied RoadRailer trailer—first and second generation European demonstration models used Boalloy curtainsider bodywork.

The US-concept trailer, which uses its own air-suspension to raise and lower the trailer on and off rail bogies.

The RoadRailer platform trailers on air-sprung BPW axles were shipped from the US to Krone's Vv'erite plant where a European. approved braking system and TIR tilt bodywork were fitted.

L Maxilode, Krone's UK service agent and partner on special projects, will launch a number of products at next month's IRTE show, including a 32-tonne payload coil carrier built for Danish operator DFDS for use at 48 tonnes gross.

The triaxle trailer is designed to carry either two 18-tonne coils or a variety of smaller coils. According to Maxilode boss Colin Ess: "It's going to run with a low-height tractor with a 1,150mm fifth-wheel height which has enabled us to design in quite a deep neck. It will have a 200mm coil well in the neck up to the landing legs and a 300mm-deep well from there on."

The load will be covered by a Norteck sliding body providing two metres clear space beneath the roof.

When the trailer is not carrying coils it can handle up to 28 Europallets on a return load.

Ess says the same design features could be used on a UK version at 38 tonnes.

Also on Maxilode's Telford stand will be a 120mm-neck ultra-lightweight intermodal skeletal trailer which can take a 13.6m swap body.

The triaxle trailer will tare out at just 4,650kg complete with a pallet rack. The show model will have ROR airsuspended axles and a EIP body finished in T1P's colours.

Maxilode is also developing a Multislide sliding bogie container trailer with improved "friction-free" operation.