Excuses don't wash

Page 114

Page 115

Page 116

If you've noticed an error in this article please click here to report it so we can fix it.

Fleet engineers are under pressure to improve vehicle cleaning routines. What sort of equipment is available? Alan Bunting looks at a cross-section

• 'Trucks get dirtier every day. Of course they do. But the truth of the statement is two-edged in that the problem of keeping vehicles clean becomes progressively more challenging as traffic congestion on British roads increases.

The average space between you and that vehicle in front which is throwing up an emulsified mixture of water, mud, grit, oil and tyre rubber — with salt added for good measure in the winter months — grows less. Road speeds are also increasing, which means more spray and hence more applied grime.

Fleet engineers responsible for vehicle maintenance are under ever more pressure to improve vehicle cleaning routines, especially in image-conscious own-account or contract distribution companies, whose liveries are designed to perform a positive sales promotion role.

It is sometimes forgotten that cleaning time is downtime. An hour spent washing a large truck, using a long-handled brush and a hose is just as disruptive to a vehicle's operating schedule as an hour carrying out mechanical repairs.

In former days many drivers came in on Saturday morning to wash their vehicles and make routine checks on fluid levels and carry out running adjustments. The economic stringencies of post-recession fleet operation have largely ruled out such niceties.

Vehicle washing without purposedesigned equipment is slow and hence unacceptably labour intensive for today's transport operators. Even the user of half a dozen delivery vans can justify invest ment in some form of portable cleaning equipment.

One of the simplest and least expensive products available, costing less than 2100 is the Jetwell Gun power washer. The whole thing is hand held, and requires a mains water connection and — this could be a problem for small operators — a compressed air supply. The spray will deliver clean (cold) water in high volumes or degreasing chemicals in low volumes for engine and under-chassis cleaning.

From KEW Industry Ltd comes a wide range of fixed or mobile (trolleymounted) machines designed in Denmark for cold or hot water or indeed steam cleaning, ranging from the small Hobby cold-water-only unit costing under &300. Pump pressures of up to 66 bar (950psi) are generated on the smallest KEW unit.

Cold water pressure cleaners, which in the last decade have come into such widespread use, many employing pressures up to 88 bar (1,300psi), rely on the sheer impact of the water particles literally to knock the dirt off, as an alternative to mechanical methods, ie brushes, flails or indeed a hand-held rag.

Caution is needed when directing a high-pressure, cold-water spray at close range at painted surfaces, unless you are sure that the primer, undercoat, top coat and any signwriting have been applied with the most diligent care. The pressure spray will quickly find any doubtfully adhering finishes. By heating the wash water, adding detergent to it, or doing both, grime is softened so that it can be shifted with less agitation (ie spray pressure action). There is therefore less risk of paintwork damage.

Another company offering a wide range of trolley mounted hot/cold pressure washers is the Warwick Pump and Engineering Co Ltd whose equipment is all British made. The mains-powered H60 machine delivers up to 9.75 litres/min at a maximum 59 bar (870psi). It will, says Warwick, tolerate contaminated water.

A 2hp donkey engine in place of an electric motor makes the Warwick H90 washer more versatile in a transport yard. It is also more powerful, generating up to 88 bar pressures. On both machines, the pistol-grip lance is available with nozzles giving four different spray angles: 0 deg (ie straight jet), 12, 25 and 45 deg. The wider-angled sprays are ideal for fast rinsing of large areas.

Where frequency of washing is sufficiently great, typically because of the number of vehicles in the fleet, the cost of a site-based semi or fully-automatic washer installation can be justified.

A surprising choice of configurations is available, most of them making use of one or more archways, through which the vehicle is driven; alternatively the arches are moved over the stationary vehicle.

Moving-arch washers, while necessarily a good deal more complex and costly than their fixed-arch (drive-through) counterparts, can be installed in more restricted transport yard locations.

Archway washers can provide sprayonly treatment, where typically a dirtlifting detergent solution is applied first, followed (after an interval during which the chemical has a chance to penetrate) by a clean water rinse.

Where vehicles are away from base for days or even weeks at a time, allowing dirt to become thoroughly ingrained, brush or flail agitation can become necessary. Such conditions are met by the rotary brush archway type vehicle cleaners now widely available.

Wickham Gensol Ltd, under the

brand name Autowash, offers a number of spray-only fixed-archway washers. The simplest is the Jet Wash 2 whose pipework arches carry fixed-angle spray nozzles. The arches come in seven sizes, accommodating vehicles from 1.83 to 4.57m high and from 2.0 to 2.9m wide.

More elaborate and of more robust construction, for washing large vehicles in exposed outdoor installations, is Wickham's Jet Clense, whose spray jets oscillate to improve penetration into corners and crevices. Both Wickham machines can be supplied with underfloor proximity sensors which trigger the wash-rinse sequence without the driver leaving his cab.

The automatic function can, however, be overridden by a manual control panel.

Three types of under-chassis and wheel wash installation can be specified as options with the Wickham machines, as can a thermostatic winter precaution device (needing a compressed air supply) which empties the water from the pipework.

Where water authorities impose consumption limitations, a water recycling/ reclamation system can be added to Wickham installations. It makes use of a 4,500litre (minimum) storage tank, and needs a three-phase electrical mains supply.

For operators who need to clean vehicles on a less regular basis, Wickham offers the type of trolley-mounted, highpressure cold and hot-water washers described earlier. Mains-electric powered models range from the 68 bar 13-litre/min '209' to the extra-high pressure 145 bar '321'. Donkey engine powered equivalents are also offered. All the machines can be fitted with a detergent injection system. Wickham supplies a range of cleaning chemicals under the Gensol name.

AVW Wilcomatic Ltd claims to be the UK's largest supplier of commercial vehicle washing equipment. It includes

single-brush units, through to five-brush moving and fixed-arch rollover machines, while the company's spray-only wash has found a novel application in washing fullyloaded car transporters (vehicle and load).

The E' machine from AVW is designed to wash road vehicles of all sizes, it has three brushes — two vertical and one horizontal — on a traversing gantry to provide a "two-pass wash" with detergent injection. The machine is micro-processor controlled, its sensing system coping with artic cab-rear panels and the fronts of dry-freight and reefer semi-trailers up to 6.5m high.

The latest addition to AVW's range is the Fleetwasher Compact, a three-brush moving-gantry machine suitable for washing vans and minibuses up to 3m high. Its optional drier system operates through two vertical ducts and a horizontal duct.

The larger Fleetmaster V five-brush machine is aimed at the larger fleet operator with vehicles up to 3m wide and 4.5m high. This has four vertical brushes — two contoured for tankers and two straight for flat-sided vehicles — together with a horizontal rollover brush. The lesselaborate Fleetwasher II is of the threebrush rollover type, suitable for vehicles up to 2.8m and 4.5m high.

The Samson machine from AVW is a drive-through bus wash available with under-chassis washing jets and a roof brush. The double contra-rotating brushes wash front, sides and rear. It incorporates a pre-rinse with detergent injection and a final rinse. The unusual, single-brush Spacesaver has a brush height up to 5.0m and is normally suspended from twodirectional overhead tracks. Like the trolley-mounted outdoor PA version it can be moved around manually. The tilt action enables inclined surfaces to be cleaned.

Options available from AVW include water reclamation, under-chassis washing, and a frost protection system which automatically switches on heat tapes around the pipework and a water pump heater, when the ambient temperature falls to 1-2 deg C. If the air temperature subsequently drops to minus 1 deg C compressed air is injected to clear the pipes. AVW says it has 90 maintenance engineers based at strategic locations throughout the UK.

Esquire Kleindienst and Co Ltd, another well-established truck and bus wash supplier, offers its 6-1677 moving gantry brush machine, which is microprocessor controlled with five variable programmes selectable for different sizes and shapes of vehicle with sixteen alternative brush pressures. The gantry is of self-supporting galvanised steel construction running on a profiled track of variable length and driven (on both sides) by direct-drive gear motors.

Side brushes are guided top and bottom in hinged brackets and overlap the centre to avoid a dirty vertical line on the front and rear of the vehicle. A diagnostic system pinpoints faults so the operator can change the relevant printed circuit board in minutes.

Operation is fully automatic, with overriding manual control and, thanks to the brush pressure variation feature, is suitable for curtain-sided and tilt trailers as well as box bodywork. A drive-through version is also available. For extra-high (up to 4.85m) vehicles a special variant is offered. Under-chassis wash and water recirculation are other listed refinements.

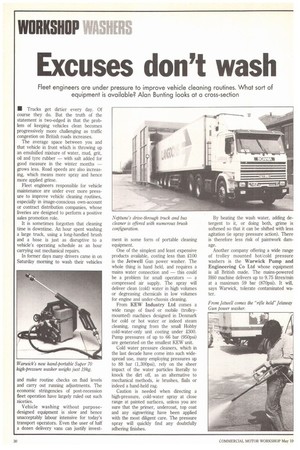

From Neptune Ltd whose experience in vehicle wash manufacturing in France goes back 16 years, comes the drivethrough "tunnel" truck wash. There are versions with four or six vertical-axis rotating brushes. A horizontal-axis roof brush is available either as a fixed-position unit or on a pivoting (up and down) frame, which takes care of roof height differences of plus/minus 500mm.

An even more sophisticated Neptune device senses vehicle height electronically, and automatically adjusts the top brush position before the vehicle gets to it. Separate rotary wheel-cleaning brushes are another extra.

Other Neptune options include an addi

tional detergent spray entry-arch, an under-chassis spray installation, a manual lance wash connection and a two-stage, heat/evacuate frost protection system.

An underfloor inductance loop starts the drive-through wash programme. Electronics are further applied in Neptune's latest so-called programmable gantry washer which applies, in sequence, a "foam bath" which is allowed to soak (so loosening the dirt) before rotary brush operation begins.

Androx Ltd, a company known for many years in the aircraft industry for its metal crack-detection products, is now a major supplier of industrial washing detergents and more recently for fixed and moving arch spray-only (non-brush) vehicle cleaning machines. An example of the Ardrox twin fixed-arch washer installed by Argyll Stores Ltd was described in last month's Workshop.

The fixed-arch system consists of two arches of supported pipework each fitted with variable angle spray jets. One applies the diluted detergent, while the second Provides a high-pressure water rinse.

Sensors detect the presence of the vehicle, and these control the operation of the multi-stage pumps and traffic lights which are incorporated in each arch. The two arches straddle the wash lane and are set apart by the length of the longest vehicle, plus 5 metres.

Another cleaning detergent supplier to branch into washing equipment hardware is Diversey Ltd, whose fixed-arch Fleetcleaner machine is unusual in its use of non-corrodible plastic pipework.

Similarly, the stainless steel tipped spray jets are fully resistant to chemical attack, ensuring constant spray pressure, while the chemical and water storage tanks are also constructed from heavy duty plastic.

An under-chassis wash can be incorporated. The wash chemical concentration is controlled electronically to eliminate wastage and ensure efficiency.

The Fleetcleaner's wash and rinse cycle is electronically controlled by a Mitsubishi programmable controller. This enables specific requirements to be tailor-made for each vehicle's dirt build-up.

From Technorizon International Ltd comes a three-brush arch-type

washer known as the Tanunermatic rainbow. A detergent pre-wash arch and an under-chassis spray attachment are available at extra cost.