Making Vehicles Fit the Roads

Page 92

Page 93

Page 94

If you've noticed an error in this article please click here to report it so we can fix it.

Experience of Overseas Users Shou's How Operators or Manufacturers can Modify Standard Production Chassis to Work More Successfully on High-crowned Roads Br Laurence J. Cotton, M.LR.T.E. INSUFFICIENT manpower and lack of finance for development prevent road improvement from keeping pace with industry in the

new . countries. Consequently, vehicles must be built to suit the roads. New Zealand, for example, has, in certain parts, a law governing maximum tyre pressures and loads, as opposed to the limits on axle weights imposed in Britain, on the Continent and elsewhere. To prevent damage to thin-skinned roads, it is necessary to impose restrictions on tyre contact loading.

Generally, the roads outside the main centres in the newly developing countries are high-crowned and have comparatively thin metalled surfaces. Because of the great distance between towns and industrial centres, it will be impracticable, for many years, to improve the present roads.

Protecting The Roads The law in New Zealand restricts maximum tyre pressure to 75 lb. per sq. in. and therefore limits the load per wheel. This provision was introduced to protect the second-class roads from rapid deterioration, but in many instances the theoretical figures are grossly different from practice.

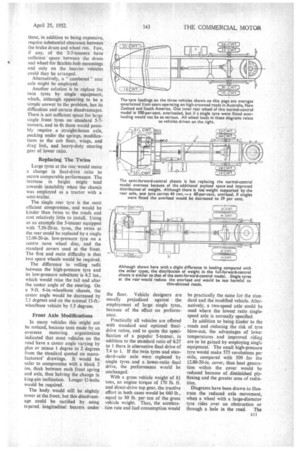

Operators and distributors in Australia, New Zealand and Venezuela have co-operated with "The Commercial ' Motor" in determining actual wheel loading of British and American 5-t6nners, measured on the camber of highcrowned roads.

The vehicles examined were normal-, forwardand semi-forward control types equipped with twin rear wheels and loaded to a gross vehicle weight of 81 tons. This gross weight was based on the advocated British home rating of 1-ton 71 cwt. per tyre, the equipment being standard 7.50-20 10ply rating.

The results indicated that the inner rear' tyres were overloaded by 60-100 per tent. These tests, were made on new vehicles with tyres inflated to 85 lb. per sq. in. The conditions imposed in New Zealand on tyre pressure_ would reduce the gross vehicle weight, by I ton 1 cwt. and likewise the degree of overloading would be less.

As a tentative method of equalizing the loading of twin tyres on each side of the axle, pressures could be adjusted, the inner tyres being underinflated and the pressure in the outer tyres raised.

Alternatively, a compromise could be made by employing worn covers on the inner wheels.

The first method would cause scuffing of the treads, with a correspondingly high rate of wear, because both wheels make the same number of revolutions per mile but the peripheries of the tyres cover different distances. To use worn covers on the inner Wheels is more practicable, but the risk of punctures is increased.

The complete solution of the problem, if twin tyres are to' be used,is to fit flexible hub mountings, but

these, in addition to being expensive, require substantial clearance between the brake drum and wheel rim, Few, if any, of the 5-7-tonners have sufficient space between the drum and wheel for flexible hub mountings and only on the heavier vehicles could they be arranged.

Alternatively, a " cambered " rear axle might be employed.

Another solution is to replace the twin tyres by single equipment, which, although appearing to be a simple answer to the problem, has its difficulties and certain disadvantages. There is not sufficient space for large single front tyres on standard 5-7tonners, and to fit them would possibly require a straight-beam axle, packing under the springs, modifications to the cab floor, wings, and drag link, and heavy-duty steering gear of lower ratio.

Replacing The Twins

Large tyres at the rear would mean a change in final-drive ratio to secure comparable performance. The increase in height might tend towards instability when the chassis was employed as a tractor with a semi-trailer.

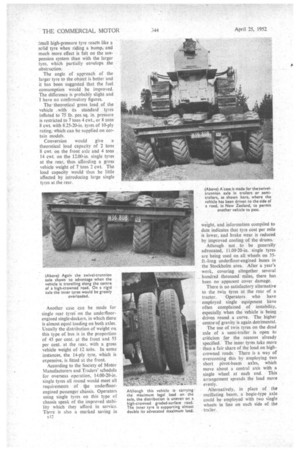

The single rear tyre is the most efficient compromise, and would be kinder than twins to the roads and cost relatively little to install. Using as an example the 5-tonner equipped with 730-20-in. tyres, the twins at the rear could be replaced by a single 12.00-20-in, low-pressure tyre on a centre nave wheel disc, and the standard covers used at the front. The first and main difficulty is that two spare wheels would be required.

The difference in rolling radii between the high-pressure tyre and its low-pressure substitute is 4.2 ins., which would raise the tail and alter the castor angle of the steering. On a 9-ft. 6-in.-wheelbase chassis, the castor angle would be decreased by 2.1 degrees and on the normal 13-ft.wheelbase vehicle by 1.5 degrees.

Front Axle Modifications

In many vehicles this might not be noticed, because tests made by an overseas motoring organization indicated that most vehicles on the road have a castor angle varying by plus or minus 1 degree to 2 degrees from the standard quoted on manufacturers' drawings. It would be safer to compromise with a block 2 ins, thick between each front spring and axle, thus halving the change in king-pin inclination. Longer U-bolts would be required.

The body would still be slightly lower at the front, but this disadvantage could be rectified by using Upered longitudinal bearers under the floor. Vehicle designers are usually prejudiced against the employment of large single tyres, because of the effect on performance.

Practically all vehicles are offered with standard and optional finaldrive ratios, and to quote the specification of a popular 5-tonner, in addition to the standard ratio of 6.27 to 1 there is alternative final drive of 7.4 to 1. If the twin tyres and standard-ratio axle were replaced by single tyres and a lower-ratio final drive, the performance would be unchanged.

With a gross vehicle weight of 81 tons, an engine torque of 170 lb. ft. and direct-drive top gear, the tractive effort in both cases would be 660 lb., equal to 80 lb. per ton of the gross vehicle weight. Thus, the acceleration rate and fuel consumption would be practically the same for the standard and the modified vehicle. Alternatively, a two-speed axle could be used where the lowest ratio singlespeed axle is normally specified.

In addition to being kinder to the roads and reducing the risk of tyre blow-out, the advantages of lower temperatures and improved riding are to be gained by employing single equipment: The small high-pressure tyre would make 575 revolutions per mile, compared with 509 for the 12.00-20-in, cover, thus heat generation within the cover would be reduced because of diminished plyflexing and the greater area of radiation.

Diagrams have been drawn to illustrate the reduced axle movement, when a wheel with a large-diameter tyre rides over an obstruction or through a hole in the road. The :rattail high-pressure tyre reacts like a solid tyre when riding a bump, and much more effect is felt on the suspension system than with the larger tyre, which partially envelops the obstruction.

The angle of approach of the larger tyre to the object is better and it has been suggested that the fuel consumption would be improved. The difference is probably slight and I have no confirmatory figures.

The theoretical gross load of the vehicle ,with its standard tyres inflated to 75 lb. pet. sq. in. pressure is restricted to 7 tons 4 cwt., or 8 tons 8 .cwt. with 8.25-20-in, tyres of 10-ply rating, which can be supplied on certain models.

Conversion would give a theoretical load capacity of 2 tons 8 cwt. on the front axle and 4 tons 14 cwt. on the 12.00-in, single tyres at the rear, thus affording a gross vehicle weight of 7 tons 2 cwt. The load capacity would thus be little affected by introducing large single tyres at the rear.

Another case can be made for single rear tyreson the underfloorengined single-deckers, in which there is almost equal loading on both axles. Usually the distribution of weight on this type of bus is in the proportion of 45 per cent. at the front and 55 per cent. at the rear, with a gross vehicle weight of 12 toils. In some instances, the 14-ply tyre, which is expensive, is fitted at the front.

According to the Society of Motor Manufacturers and Traders' schedule for overseas operation, 14.00-20-in. single tyres all round would meet all requirements of tite underfloorerigined passenger chassis. Operators using single tyres on this type of chassis speak of the improved stability which they afford in service. Thi:re is also a marked saving in

Although this vehicle is carrying the maximum legal load on the axle, the distribution is uneven on a high-crowned graded-surface road. The inner tyre is supporting almost double its advocated maximum load.

weight, and information compiled to date indicates that tyre cost per mile is lower, and brake wear is reduced by improved cooling of the drums.

Athough not to be generally advocated, 11.00-20-in, single tyres are being used on all wheels on 35ft-long underfloor-engined buses in the Stockholm area. After a year's work, covering altogether several hundred thousand miles, there has been no apparent cover damage.

There is no satisfactory alternative to the twin tyres at the rear of a tractor. Operators who have employed single equipment have often complained of instability, especially when the vehicle is being driven round a curve. The higher centre of gravity is again detrimental.

The use of twin tyres on the dead axle of a semi-trailer is open to criticism for the reasons already specified. The inner tyres take more than a fair share of the load on highcrowned roads. There is a way of overcoming this by employing two short pivot-beam axles, which move about a central axis with a single wheel at each end. This arrangement spreads the load more evenly.

Alternatively, in place of the oscillating beam, a bogie-type axle could be employed with two single wheels in line on each side of the trailer.