Design for Easy Maintenance

Page 88

Page 89

Page 90

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

By P. A. C. Brockington A.M.I.Mech.E. TO describe a certain engine or chassis feature as one which promotes ease of maintenance, is to invite criticism from the designer who can claim that a similar component or assembly, produced by his concern, has better wearing properties. He might point out that, ideally, one of the objectives of development work should ' be to dispense with the need for

maintenance. • • All manufacturers must at times be faced with the alternatives of producing a part which may be readily adjusted for wear or replaced, and of providing a component, probably at greater cost, which would not require any attention during the stipulated running period. In terms of maintenance economy, both may have an equal claim to merit.

The purpose of this article is to indicate some of the ways in which normal overhaul jobs havo been facilitated by the skill and ingenuity of designers. Although improvements which prolong the mileage life of a vehicle between overhauls are in a different category, they are often so closely related that mention is mach of some examples which are applicable to current maintenance problems.

The advent of underfloor-engined chassis aroused doubts regarding engine-maintenance difficulties, and it is appropriate to quote dismantling times of the first flat engine to be produced commercially in this country and the only one of its type to be fitted in a goods vehicle.

To remove the valve-rocker gear and cylinder heads of The Sentinel four cylindered oil engine, when fitted in the chassis, occupies 45 minutes. This is alsO the time taken for the removal of the timing cover after the injection pump has been detached, the latter operation taking 7 minutes. The back plate can be unbolted and the pistons and connecting rods withdrawn through the tops of the bores in 30 minutes.

E6 The complete engine, gearbox and clutch unit can be changed in approximately 11 hours, and. it is noteworthy that no special equipment is necessary for handling or supportin; the assembly for any of these operations. Every job may be carried out on the floor of the garage from underneath the chassis, so that the engine of a fully laden vehicle may be overhauled without using a pit or removing the load.

• Amongst other. underfloor engines with injector pumps which may be dismantled without the removal of trap doors or the use of a pit are the A.E.C. and Midland " Red " Both are designed for easy access to the valve gear, cylinder heads and, injectors. By employing built-in lifting gear, the underfloor engine of the A.E.C. Regal Mark IV may be removed and replaced in under 30 minutes.

A wheeled engine-trolley with corner bottle jacks

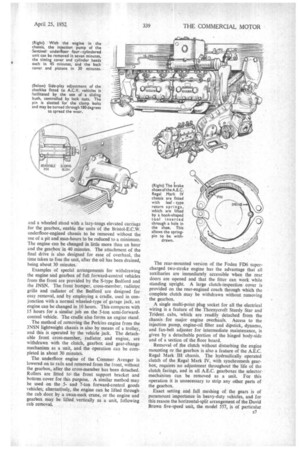

and a wheeled stand with a lazy-tongs elevated carriage for the gearbox, enable the units of the Bristol-E.C,W. underfloor-engined chassis to be removed without the use of a pit and man-hours to be reduced to a minimum. The engine can be changed in little more than an hOur and the gearbox in 40 minutes. The attachment of the final drive is also designed for ease of overhaul, the time taken to free the unit, after the oil has been drained, being about 30 minutes.

Examples of special arrangements for withdrawing the engine and gearbox of full forward-control vehicles from the front are provided by the S-type Bedford and the INSN. The front bumper, cross-member, radiator grille and radiator of the Bedford are designed for easy removal, and by employing a cradle, used in conjunction with a normal wheeled-type of garage jack, an engine can be changed in 10 hours. This compares with 15 hours for a similar job on the 5-ton serni-forWardcontrol vehicle. The cradle also forms an engine stand.

The method of removing the Perkins engine from the JNSN lightweight chassis is also by means of a trolley, and this is operated by the vehicle jack. The detachable front cross-member, radiator and engine, are withdrawn with the clutch, gearbox and gear-change mechanism as a unit, and the operation can be completed in about 30 minutes.

The underfloor engine of the Commer Avenger is lowered on to rails and removed from the front, without the gearbox, after the cross-member has been detached. Rollers are fitted to the front support bracket and bottom cover for this purpose. A similar method may be used on the 5and 7-ton forward-control goods vehicles; alternatively, the engine can be lifted through the cab door by a swan-neck crane, or the engine and gearbox may be lifted vertically as a unit, following cabremoval.

The rear-mounted version of the Foden FD6 supercharged two-stroke engine has the advantage that all auxiliaries are immediately accessible when the rear doors are opened and that the fitter can work while standing upright. A large clutch-inspection cover is provided on the rear-engined coach through which the complete clutch may be withdrawn without removing the gearbox.

A single multi-point plug socket for all the electrical wiring is a feature of the Thomycroft Sturdy Star and Trident, cabs, which are readily detached from the chassis for major engine overhauls. Access to the injection pump, engine-oil filter and dipstick, dynamo, and fan-belt adjuster for intermediate maintenance, is given by a detachable portion of the hinged body-side and of a section of the floor board.

Removal of She clutch without disturbing the engine mounting or the gearbox is also a feature of the A.E.C. Regal Mark III chassis. The hydraulically operated clutch of the Regal Mark IV, with synchromesh gearbox, requires no adjustment throughout the life of the clutch facings, and in all A.E.C. gearboxes the selector. mechanism can be removed as a unit. For this operation it is unnecessary to strip any other parts of the gearbox.

Exact setting and full meshing of the gears is of paramount importance in heavy-duty vehicles, and for this reason the horizontal-split arrangement of the David Brown five-speed unit, the model 557, is of particular

maintenance interest. During initial building and in any subsequent maintenance work, correct adjustment can be ensured before final assembly; this also applies to the forks. and selector mechanism, which are housed in the lower half of the box. The unit has a centre bearing, which obviates the use of a spigot bearing, the latter feature being described as possibly the most frequent cause of gearbox trouble.

The Moss five-speed gearbox has separate brackets for selector-rod mounting, and these are assembled before the cover is fitted; adjustment is easy, and correct setting is certain.

The statement by the London Transport Executive that a fluid coupling and Wilson epicyclic gearbox run for over 200,000 miles before removal for overhaul is evidence of their freedom from maintenance troubles. When dismantling becomes necessary, each epicyclic train is handled as a separate unit, spare brake-bands with new linings are fitted as required and the parts re-assembled in the casing independently of the selector mechanism, which is •mounted on a side cover. The air-operated version of the box provides a further degree of simplification, no bus-bar being required.

A valuable maintenance feature of the _Moss standard .hypoid axle is the assembly of the entire differential gear as a unit, which can be withdrawn from the casing

in hr., including the time required for removing the upset side shafts. The David Brown designers emphasize the maintenance advantage of worry drive when each worm wheel is matched against a master worm to ensure interchangeability. This avoids the necessity of replacing both gears in the event of the failure of one of the components.

Reverting to engine features, the ease with which prefinished slip-fit cylinder liners can be removed is art advantage which many operators have used to reduce overhaul times. In some instances, the liners are removed at an intermediate overhaul, turned through 180 degrees and replaced for further service, thereby • maintaining performance and reducing oil consumption.

100,000 Miles Before Dismantling

Removing the Bedford S-type engine for a rebore has been obviated by employing slip-fit cylinder liners, and the long-wearing properties of the •induction-hardened crankshaft, running in copper-lead bearings, enables a vehicle to cover 100,000 .miles or more, before it becomes necessary to dismantle the. engine.

Interesting recommendations are made by Foden designers regarding lubricating oil and fuel filtration. When the oil filter is of a design which can be cleaned, it is preferable that the flow should be inwards, so that the sludge may be more readily removed. In addition to the oil-fuel filter which is dismantled for cleaning on the vehicle, an auxiliary oil-fuel filter should be used to trap any dirt left in the main filter when it was serviced. The auxiliary filter should be dismantled only when it can be handled under scrupulously clean conditions in the workshops.

The provision of a sump plate for initial inspection of the crankshaft assembly and the removal of sludge is recommended by the Foden concern. The sump of the Daimler CVD6 engine is fitted with large inspection plates, which enable the connecting-rod assemblies to be dismantled and the main bearings to be checked with the sump in place. This modification was introduced to meet the requests of operators.

The adjustment of a timing chain is sometimes a necessity which wastes much vehicle running time, as it often requires removal of the timing case and must be performed between normal overhaul docks. On the latest Gardner engines, the chain is adjusted with the case in position, and a recent modification provides

1:3 .

automatic correction of valve and fuel-pump timing. Other examples of automatic chain tensioning include all the engines in the Thornycroft range, with the exception of the smallest petrol unit, which is fitted with an external means for increasing the tension.

On all A.E.C. engines, the starter rings are a push fit on the flywheels. There are three keyways, which provide six alternative positions for changing the point of maximum wear.

What is described as a design feature for preventive maintenance of Perkins engines is the provision .of a crankcase breather system, by which vapours are drawn from the crankcase and cylinder-head cover into the inlet manifold, thereby reducing condensation and lubricating-oil contamination. Under this heading may also be included the lubriciting system, which is designed to maintain a controlled Cow of oil to bearing surfaces \after clearances have been increased because of wear.

The crankshafts of the Gardner engines, being hardened and tempered, may be cold straightened within.

reasonable limits, and the journals may be repeatedly reduced in diameter for fitting undersize white-metal bearings.

The new upswept frame of the E.R.F. chassis is described as "a logical development in relation to body and frame construction," in that it does not affect the unladen height of the body and permits easier servicing of the major components. The assembly of the frame represents the modern trend of bolting the cross-members to the main members with plug-fitting high-tensile bolts, which are easily removed when damaged members are replaced.

A reduction in shackle-pin wear is claimed on account of the overhead road spriugs, which have less camber than the underslung type. The self-adjusting ball-socket ends of the steering joints are also representative of a trend which is of value as a preventive-maintenance feature.

A principle of maintenance interest employed in the construction of the Scammell Scarab mechanical horse chassis is to use a large number of bolts, instead of relying upon fitted bolts in reamed holes. • The spring-loaded, self-adjusting steering-joint ends of the Sunbeam trolleybus chassis are readily dismantled by removing the end plugs. On the concern's export chassis, with extended front overhang, a single side steering tube is employed, which eliminates relay levers and reduces the number of wearing parts. An interesting feature of the shackle assemblies is the provision for withdrawing the hard-chromiumed pins from inside the frame to obviate the possibility of body. interference. The shackles are adjustable for side play.

On the front suspension layout of the Scamrnell Scarab mechanical horse, the only servicing required is the topping-up of the oil-filled cylinder in which the piston and spring are housed and the occasional greasing of the hub.

An example of the use of rubber-shackle-bushes is found on the B.U.T. trolleybus chassis, which have Leyland-Metalastik rubber-tometal-weld bushes. The rubber acts in shear, and there are no bearing surfaces to lubricate.

A sliding bush in the shackles of A.C.V. chassis enables side play to be taken up by tightening the pin bolt, and in the latest design of the fully articulated rear bogie, the shackle pins are clamped by caps. This makes for easy removal when replacement becomes necessary. On the A.E.C. Regal Mark IV chassis, brake-shoe removal is facilitated by the use of a leaf-type retainer spring which is lifted by a hook-shaped tool inserted through the back plate. Special care has been taken in the design of the Sunbeam trolleybus hub-assemblies to provide greasedeflector plates of a type that eliminates the possibility af lubricant reaching the brake facings.

The brake drums of B.U.T. trolleybuses are on the autside of the hub flange, and can be removed without disturbing the hub assembly. The hand-brake mechanism is housed in an oil bath and . all brake relay levers, camshafts and cross-shafts have prepacked bearings to obviate the need for lubrication between major overhauls. The totally enclosed pawl-and-rack mechanism of the Sunbeam trolleybus chassis is so designed that the pawl is held out of mesh in the "off" position, where the highest rate of wear occurs. Referring to the smaller types of vehicle, the Bradford 8-h.p. chassis was specially designed for commercial work, and the simplicity of maintenance operations has not been sacrificed to styling considerations. Neither the radiator nor gearbox need be disturbed when the horizontally opposed engine is removed, and a detachable cover in each mudguard gives access to the cylinders for head or assembly dismantling with the engine in place.

The approximate time quoted for removing the engine from the chassis, unpacking the replacement unit, packing the worn engine in the case, fitting a new engine in the chassis, and tuning and testing is 8 man-hours. Stripping the cylinders, fitting reconditioned connecting rods and re-asse.ubling occupy about 12 man-hours. The four-cylindered.engine and gearbox of the Reliant three-wheeler arc mounted on a subframe which can be dropped from the chassis in the minimum of time. The central position of the engine in the cab renders the unit accessible from both sides.

The replacement of a Ford V8 or 10-h.p. unit from a stock of reconditioned engines by appointed agents within a day, is a service which ensures operational continuity. The design simplification of the Perkins engines, backed by a widespread spares organization and instructional courses, relieves the operator of. many overhaul problems.