MORE SPACE in

Page 86

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

NEW BEDFORD

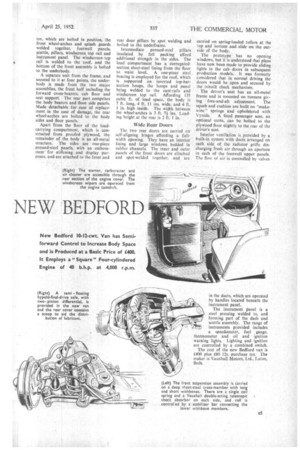

ALTHOUGH smaller in overall dimensions than its predecessor, the latest Bedford 10-12-cwt. van, a semi-forward-control model, has 18 per cent. greater body space and is more manoeuvrable. It employs a four-cylindered petrol engine and reinforced transmission, in a special frame designed for semi-forward control, and has an all-steel body which is practically devoid of compound curves or pressings involving high tooling expense.

A " Square " Engine

The engine is a new "square' unit of 3i-in. bore and 3-in, stroke, which provides 12 per cent. more power than the preceding P.C. model. Prototype tests of the new unit have shown marked economy and durability, because of the low internal friction and moderate piston speed afforded by the short stroke.

The maximum ouput is 40 b.h.p. at 4,000 r.p.m. and 71 lb.-ft. torque at 2,000 r.p.m. The engine has push-rodoperated overhead valves, and a three bearin g crankshaft carried in white-metal-lined bearings. It is offset in the frame to provide additional space on the driver's side of the cab. Power curves for the new engine, compared with the old, show an improvement in .top-gear performance. The torque curve is flatter and the b.h.p. curve rises steadily all the way to 4,000 r.p.m. The h.h.p. curve of the old engine started to fall off at 3,500 r.p.m.

The three-speed synchromesh gearbox, used in conjunction with a Borg and Beck 71-in.-diameter clutch, has steering-column control and is provided with an outrigger bearing at the rear giving additional support to the mainshaft. The rear axle has hypoid drive, and a scoop is attached to the rear cover for improved oil distribution.

The frame is a conventional allwelded structure with centre cross

bracing, the ends of which are extended to the extremities of the channelshaped side members, thus forming a • box section. The front cross-member is bolted in position, so that it can be removed for ease of engine replacement.

The front suspension assembly comprises a deep sheet-steel cross-member, secured to the underside of the chassis frame, with long and short wishbones _ connected to a single coil spring and a _ Vauxhall double acting telescopic shock absorber on each side. Roll is controlled by a stabilizer bar connecting the lower wishbone members.

Conventional semi-elliptic springs are employed at the rear.Stability is promoted by an increase of 3 ins, in the front and rear track, and by inclining the Vauxhall telescopic shock absorbers at the rear.

Turning in 33 ft.

The wheel positions are arranged for the most favourable distribution of load, and the short wheelbase of 7 ft. 6 ins., coupled with a good lock, affords a turning circle of approximately 33 ft. Tyres of 6.00-16-in. section are standard equipment.

The Bedford C.A. model is unusual in appearance. Its snub nose, covering the radiator and fore part• of the engine, has a relatively small top bonnet cover giving access to the distributor, coil and petrol pump, whilst the carburetter and starter are

reached through a panel in the cab 4 The front assembly comprises the radiator support frame and air deflec

tor, which are bolted in position, the front wheel-arches and splash guards welded together, footwell panels, scuttle, pillars, windscreen top rail and instrument panel. The windscreen top rail is welded to the roof, and the bottom of the front assembly is bolted to the underbody.

A separate unit from the frame, and secured to it at four points, the under. body is made from the two major assemblies, the front half including the forward cross-bearers, cab floor and seat support. The rear part comprises the body bearers and floor side panels. Made detachable for ease of replacement in the case of damage, the rear wheel-arches are bolted to the body sides and floor panels.

Apart from the floor of the loadcarrying compartment, which is constructed from proofed plywood, the remainder of the body is an all-metal structure. The sides are one-piece pressed-steel panels, with an embossment for stiffening and display purposes, and are attached to the front and rear door pillars by spot welding and bolted to the underfrarne.

Intermediate pressed-steel pillars insulated by felt packing afford additional strength in the sides. The load compartment has a corrugatedsection sheet-steel lining from the floor to waist level. A one-piece steel bracing is employed for the roof, which is supported on inverted top-hatsection hoops, the hoops and panel being welded to the cant-rails and windscreen top rail. Affording 135 cubic ft. of toad space, the body is '7 ft. long, 4 ft. 11 ins, wide, and 4 ft. I in. high inside. The width between the wheel-arches is 3 ft. 7i ins. Loading height at the rear is 2 ft. 110.

Wide Rear Doors

The two rear doors are carried en self-aligning hinges affording a fullwidth opening. They have an interior lining and large windows bedded in rubber channels. The inner arid outer panels of the front doors are clinched and spot-welded together, and are carried on spring-loaded rollers at the top and bottom and slide on the outside of the body.

The prototype has no opening windows, but it is understood that plans have now been made to provide sliding lights in the cab doors in subsequent production models. It was formerly considered that in normal driving the doors would be open and secured by the inbuilt check mechanism.

The driver's seat has an all-metal frame and is mounted on runners giving fore-and-aft adjustment. The squab and cushion are built on "snakewire" springs and upholstered with Vynide. A fixed passenger seat, an optional extra, can be bolted to the plywood floor slightly to the rear of the driver's seat.

Interior ventilation is provided by a built-in system with ducts arranged on each side of the radiator grille discharging fresh air through an aperture in each of the footwell upper panels. The flow of air is controlled by valves