Progress in

Page 114

Page 115

Page 116

Page 117

Page 118

If you've noticed an error in this article please click here to report it so we can fix it.

Design and Performance

BRITISH manufacturers do not alter the frontal styling of their vehicles and call them new models. The user knows that when a new design is announced, it will have either improved performance or longer life, or both, than the type which it supplants. For this reason, British manufacturers are often regarded as conservative in their policy. They do not encourage the frequent announcement of alleged " new " models merely to publicize their products, but prefer to investigate any potential alteration in design and incorporate it after it has been fully proved. Manufacturers are meeting increasing difficulty in introducing new models or making any change in design because of the prevalent shortage of materials, particularly castings, and new machine tools. Orders for castings of an existing pattern may not be fulfilled under 16 months, and much greater delay is experienced should there be any change in the design. This alone might prevent a complete change in design or major alterations from being made more frequently than at three-yearly intervals.

The Government ruling that the bulk of vehicle production should be exported, has caused manufacturers to give even closer consideration to overseas requirements. In terms of fuel economy, this policy may not always have been to the benefit of the home user, because the larger engines, heavier-duty transmission systems and strengthened frames demanded overseas, have mostly added to the unladen weight. Although by intensive research, engines have improved in efficiency, it cannot be claimed that the heavier presentday model is always as economical as the earlier vehicles which had smaller engines in lighter chassis.

The greatest advances in performance have been in improved acceleration, ability to operate faster schedules, and better braking. Maintenance engineers have benefited by the increased life of the engine and other components, which permits docking and major repairs to be spaced at wider intervals.

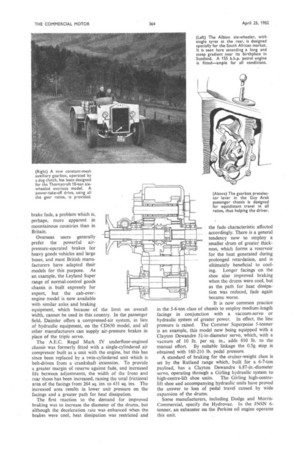

There has been a marked advance in petrol-engine development, as exemplified by the unit fitted to the larger Bedford chassis. By alterations to the carburation and manifolding, the power output of the Bedford six-cylindered unit has been increased by 16i per cent., whilst other developments have been made to promote longevity. Engine fife can be said to be governed by the bearing and bore wear. In the Bedford, an induction-hardened crankshaft, copper-lead-lined bearings, an oil-bath air cleaner, controlled breathing, and chromium-plated top rings, keep this wear to a minimum.

Maintenance engineers in charge of Bedford chassis with the " long-life " engines report from 30-50 per cent, increased mileage before reboring or crankshaft regrinding is required. Although, according to their reports, there has been no great improvement in fuel consumption, an ultimate economy has been noted, because engines have retained their peak performance for a greater mileage.

The Commer engine designers have attacked the problem of cylinder wear by pioneering chromiumplated bores, and the side-valve unit has been replaced by an overhead-valve petrol engine, affording a 7 per cent. increase in power and 14 per cent. in torque.

There have been many improvements in power output per litre in both petrol and oil engines, and, in addition to the Bedford and Commer units, other notable developments include the 3.7-litre Dennis, in which the output has been raised from 70 to 80 b.h.p. by changing from side to overhead valves, and the new Morris-Commercial 4.25-litre petrol engine which develops 100 b.h.p.

In the oil-engine field, the Crossley 8.6-litre unit, with cold-air intake and revised porting, now develops 114 b.h.p., an increase of 14 per cent., whilst the Perkins 433-litre engine is available with a normal output rating of 70 b.h.p., or, in its revised form, with machined heads and raised governed speed, 79 b.h.p. Some manufacturers still specify the Perkins engine with its lower rating because a heavier transmission system is required in certain models to accommodate the increase of torque.

Modifications in the Gardner range of engines have also been responsible for power increase without alteration to the bore or stroke dimension. The 8.4-litre unit, for example, now has an output of 112 b.h.p., compared with the 102 b.h.p. developed before the changes were introduced. The Leyland Comet, formerly equipped with a 5-litre oil engine developing 75 b.h.p. now embodies a.5.76-litre unit, which develops 91 b.h.p. All the petrol and oil engines mentioned have increased output measured in terms of unit-litre capacity.

Improved Oil Filtration It has already been mentioned that the life of an engine is governed by its bore and crankshaft wear, which may be reduced by efficient air filtration. There are other factors affecting wear, including a constant supply of clean oil. Most manufacturers now fit an external filter. Equal in importance is an adequate supply of lubricant to cool the working parts. Elevated temperatures of bearing surfaces increase the rate of wear, with resultant shortening in life of all working parts, ultimately leading to the need for premature overhaul.

Engine designers are alert to methods of improving life, and those responsible for the Commer overheadvalve engine have equipped it with a large-capacity pump passing 6i gallons per minute at 3,000 r.p.m. The Austin engineers, on the other hand, have specified a larger-capacity sump, produced from a one-piece pressing, to ensure that the lubricant is adequately cooled. This, in turn, ensures that the lower sections of the pistons and bearings are kept at a normal working temperature.

The speed barrier of the direct-injection engine, 2,000 r.p.m., has been overcome by promoting turbulence in the higher range, and because of this, Perkins, Leyland and Morris-Commercial offer higher performance in their respective products. In the new design of engine in the Leyland Comet, there has been a further improvement by offsetting the gudgeon pin by 0.060-in. from the centre line of the piston, thereby affording smoother and quieter running.

Synonymous with the Trojan 15-cwt. van is the twocylindered two-stroke petrol engine which is fitted. Recent developments in this unit include a new design of cylinder head, which has improved the idling characteristic, and the engine is claimed to be as smooth in operation as a conventional four-stroke. The output has also been raised by this modification to the extent of 7 per cent., and the torque developed is 75 lb.-ft. at 1,000 r.p.m.

There have been many changes in transmission systems, dog-engaged constant-mesh gearboxes, synchromesh units and preselective boxes all increasing refinement and performance. Leyland engineers are firm in their views that the clutch operates more efficiently when well cooled. For this reason, all their range of chassis, incorporating single-dry-plate clutches, have radially slotted facings, which, together with holes drilled in the flywheels, induce a cooling current of air. Propeller-shaft rattle at low speed, technically known as torsional oscillation, is a problem which appears mostly in oil-engined chassis. After considerable research the Borg and Beck flexible-centre-plate clutch and Metalastik rubber-bonded units, have been developed to overcome it. The Leyland Cornet 90 employs a flexible centre plate and during tests by "The Commercial Motor," no torsional vibration was discerned when travelling at low speed in top gear.

The practice of fitting synchromesh gearboxes has, in the main, been confined to private cars, but credit is due to the Bedford engineers for specifying this type of unit, with constant-mesh engagement, in quantity-production 5-tonners and 7-tonners. Not only is this unit foolproof in the selection of ratios, but its quieter operation lessens driving fatigue.

Constant-mesh gearboxes are generally employed in British goods chassis, but it is unusual to find an auxiliary gearbox with constantmesh gears and dog engagement, such as is fitted to the latest Thornycroft 10-ton six-wheeler, a number of which has been ordered for operation in South Africa. This auxiliary box has, in addition, a power-take-off drive, and with this arrangement all ratios, including reverse, may be used.

An easy-change auxiliary box is also a feature of Foden heavy-duty vehicles, and this unit is especially popular with overseas users. In the Foden the engaging dog between direct and indirect drive is spring-loaded on its selector, so that the auxiliary lever can be moved to its alternative position, but the teeth do not mate until the speed of the dog and the gear are aligned. This, in effect, affords preselection in the auxiliary ratios, thereby speeding up gear-changing when negotiating a gradient.

The constant-mesh gearbox is relatively new in British underfloor-engined passenger-vehicle design, but

30 " BEDFORD

a

Ui

0 it is found in the Atkinson, A.E.C., Guy and Leyland. The Leyland Royal Tiger and the Olympic integralconstruction single-decker have a synchromesh gearbox which is available with air or vacuum assistance to lighten ttle movement of the fever. Because of the linkage between the selector lever and the gearbox mounted amidships, the action is somewhat heavier on underfloor-engined models, especially if the intermediate bearings in the relay be tight, or the lubricant heavy. This aid provided in the Leyland makes for smoother and more rapid gear-changing.

An overdrive-top constant-mesh gearbox has recently been developed by A.E.C., Ltd., to provide a higher maximum speed in the Regal III chassis when it is operated overseas. This unit is remotely mounted in resilient bushes, and is equipped with a clutch brake which operates on a drum fitted to the input shaft.

Increased use of the A.E.C. Mammoth Major overseas has been followed by the introduction of two new fully articulated bogies w for this particular model. The cc worm-driven bogie, with an inter axle differential, is intended for u general use where the vehicle is likely to operate over good and indifferent road surfaces. The bevel-type bogie, built for extended off-the-road operation where the possibility of tyre scrub would be negatived by wheel slip, is not equipped with a third differential. In the third differential, which has spiral-bevel and double helical gear reduction, the bevel gear is arranged so that the crown wheel overhangs its bearings and the pinion shaft is extended beyond the crown wheel to provide a through drive to the second axle.

Major advances in design for improved performance have be made in power-operated, or assisted, braking systems. They have been dictated partly by the higher output of engines and partly by the need to combat brake fade, a problem which is, perhaps, more apparent in mountainous countries than in Britain.

Overseas users generally prefer the powerful airpressure-operated brakes for heavy goods vehicles and large buses, and most British manufacturers have adapted their models for this purpose. As an example, the Leyland Super range of normal-control goods chassis is built expressly for export, but the cab-overengine model is now available with similar axles and braking equipment, which because of the limit on overall width, cannot be used in this country. In the passenger field, Daimler offers a compressed-air system, in lieu of hydraulic equipment, on the CD650 model, and all other manufacturers can supply air-pressure brakes in place of the triple servo.

The A.E.C. Regal Mark IV underfloor-engined chassis was formerly fitted with a single-cylindered air compressor built as a unit with the engine, but this has since been replaced by a twin-cylindered unit which is belt-driven from a crankshaft extension. To provide a greater margin of reserve against fade, and increased life between adjustments, the width of the front and rear shoes has been increased, raising the total frictional area of the facings from 264 sq. ins. to 431 sq. ins. The increased area results in lower unit pressure on the facings and a greater path for heat dissipation.

The first reaction to the demand for improved braking was to increase the diameter of the drums, but although the deceleration rate was enhanced when the brakes were cool, heat dissipation was restricted and the fade characteristic affected accordingly. There is a general tendency now to employ a smaller drum of greater thickness, which forms a reservoir for the heat generated during prolonged retardation, and is ultimately beneficial to cooling. Longer facings on the shoe also improved braking when the drums were cool, but as the path for heat dissipation was reduced, fade again became worse.

It is now common practice in the 5-6-ton class of chassis to employ medium-length facings in conjunction with a vacuum-servo or hydraulic system of greater power. In effect, the line pressure is raised. The Commer Superpoise 5-tonner is an example, this model now being equipped with a Clayton Dewandre 5I-in-diameter servo, which, with a vacuum of 10 lb. per sq. in., adds 810 lb. to the manual effort. By suitable linkage the 0.5g stop is obtained with 160-210 lb. pedal pressure.

A standard of braking for the cruiser-weight class is set by the Rutland range which, built for a 6-7-ton payload, has a Clayton Dewandte 6.87-in.-diameter servo, operating through a Girling hydraulic system to high-centre-lift shoe units. The Girling high-centrelift shoe and accompanying hydraulic units have proved the answer to loss of pedal travel caused by wide expansion of the drums.

Some manufacturers, including Dodge and MorrisCommercial, specify the Hydrovac. In the JNSN 6tonner, an exhauster on the Perkins oil engine operates this unit.