British Trailer Makers Study the Customer

Page 106

Page 107

Page 108

Page 109

If you've noticed an error in this article please click here to report it so we can fix it.

By P. G. Tucker

engine position. In Hong Kong and Malaya there has been a demand for buses employing this layout, and in South Africa and Australia the underfloor-engined chassis has yet to be completely accepted. No doubt these operators will eventually begin to seek additional passenger capacity without extensive alteration of accepted vehicle dimensions.

Here the rear-engined chassis will no doubt prove acceptable. Little alteration of existing service technique is required to deal with this layout, and maintenance is greatly facilitated.

Another problem for which manufacturers have to cater, is that of the boom town which has sprung up rapidly with little consolidation of existing public utilities. The town has eventually settled down, but often its extent is out of all proportion to its population. Travel between homes and town centres or factory estates is a serious problem in such cases.

For these conditions, Britain can offer the articulated bus, composed of a relatively low-powered tractor and a long semi-trailer body. Operating on limited-stop services, these buses offer low running costs and high revenue-earning capacity, points of value to operators in new towns with unstabilized traffic demands.

Where the standard of living is high and social development complete, the trolleybus has definite advantages. Its silence is valuable in cities where industrial noise is absent. The presence of locally owned electric supply plants can also turn the scales in its favour.

Whatever the service and social circumstances of a populated area, there is always a British vehicle capable of meeting the local problem. It is true that no 12-cylinder 250 b.h.p. 60-ft.-long petrol-engined buses are made in this country, but this is because the vehicles built in this country offer economy, serviceability and a standard of comfort implicit in the words "public service." BRITISH trailers and semi-trailers have penetrated nearly every part of the world and production is gradually expanding. Exports of special types such as are employed principally for oilfields work and logging are notably healthy. In most of these cases, the vehicles have to be designed in the closest co-operation with the user, because conditions of topography and climate vary widely. It is equally important for the maker to know the nature of the loads for which the trailers are required, and the methods normally adopted in loading and unloading.

Local regulations concerning the construction and use of motor vehicles must also be studied. In Switzerland, for instance, the regulations are strict and are rigidly enforced, whereas in some other countries they are generous, both in respect of vehicle width and overall length. Then, again, there are the questions of permissible axle loads, braking efficiency and lighting.

An " Overseas " Design Impracticable Such design variations make it difficult for Britain to produce an overseas type calculated to meet all demands, although it is frequently possible to modify the standard general-purpose model to 'meet the needs of the majority of overseas operators. For instance, in nearly all cases a demand is made for a high degree of braking efficiency, and this can usually be met by fitting larger brake drums and shoes to give increased frictional area. The two-line air-pressure braking system is that most generally called for.

Tyre size is important, because if the maker were to fit an unusual size difficulties might be experienced when the time for renewal arrived. For this reason, it is usual to fit 11.00-20 tyres, as most exported tractive units are thus equipped.

The delivery date is usually of great importance to prospective overseas buyers, and for this reason it is essential that the customer should help himself and the trailer maker by giving in his initial inquiry the fullest information of his requirements. Trailer makers are frequently asked: "Please forward us your best quotation and earliest delivery date for trailers to carry machinery." Unless the manufacturer had previously supplied the inquirer with trailers for this work, it would be impossible to give a quotation without further correspondence.

Some of the particulars which the maker needs to know before he can give a firm quotation are the nature and weight of the loads normally to be carried, the kind of roads over which the outfit will be operated and, where possible, the make and size of the tractive unit normally to be employed. To the Briton who stays at home, overseas operation immediately suggests bad roads, but this is by no means generally the case. If a trailer is to carry hea-,y loads over rough ground, the maker has to think in terms of articulated wheel assemblies and possibly modifications to an existing suspension system, but if general goods are to be hauled at high speed on some of the long stretches of flat highway in South America, for example, a modified standard product might meet the operator's needs.

From opinions expressed by the leading trailer makers in this country, it would seem that overseas demands for other than specialized types can be met without devising an overseas design, but this does not mean that buyers have to accept the standard 13ritish product which most nearly meets their requirements.

Where the trailer maker can meet a customer's demands with a standard product, it is to the benefit of all concerned that he should do so, but where this is not possible either the standard product is modified, or the customer is given a quotation based on a completely new design.

Construction technique may be influenced by the need for economy in shipping space. In many instances, shipping costs can be greatly reduced by adopting a bolted form of construction, instead of all-welded, for the frame. If, for instance, the cross-members be bolted to the main longitudinal members, the assembly can be completely broken down for shipment. This, therefore, is frequently done, and is in the interest of both the maker and the buyer.

Another aspect of this form of construction concerns maintenance. If a trailer be involved in an accident and a frame member be badly bent, it is far easier to introduce a new member in a bolted assembly than would be the case with an all-welded frame. Where vehicles undertake hauls of hundreds of miles from their bases, the question of maintenance is particularly important. Thus, wherever possible, trailer makers try to give maximum protection to gears or screw drives, such as are used for leg raising and to shackle bolts and suspension components. These provisions are most important in dusty country.

The trailer maker who mentioned these points to me met such conditions by supplying a rubber-mounted suspension system, together with special filters for the brake-operating mechanism.

A vital aspect of semi-trailer operation is that concerned with the interchangeability of units, and this, of course, is bound up with the type of turntable on the tractive unit. American tractive units fit the S.A.E. fifth-wheel type and if prospective overseas buyers who operate American tractive units omit to mention this feature, it may lead to much unnecessary correspondence.

British trailer makers are, however, fully alive to the importance of supplying the right pattern of turntable and they look to prospective buyers to give the fullest information in their initial inquiries.

As an instance of the keenness of British manufacturers to meet overseas demands, I quote the case of a maker of horsebox trailers, a number of which was required for use in Switzerland. It was found that the standard product was too wide to pass the construction regulations in that country. The only possible way to modify that trailer was to recess the wheels into the body, and this bad to be done without encroaching unduly on the interior space. It was, however, successfully accomplished, and the order was secured.

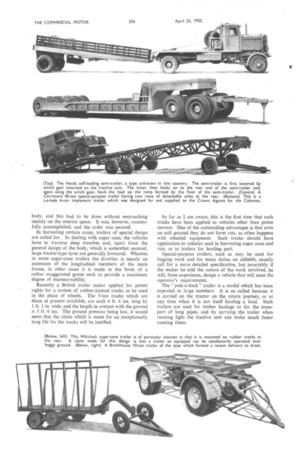

In harvesting certain crops, trailers of special design are called for. In dealing with sugar cane, the vehicles have to traverse deep trenches and, apart from the general design of the body, which is somewhat unusual, large tractor-type tyres are generally favoured. Whereas in some sugar-cane trailers the drawbar is merely an extension of the longitudinal members of the main frame, in other cases it is made in the form of a rather exaggerated goose neck to provide a maximum degree of manteuvrability.

Recently a British trailer maker applied for patent rights for a system of rubber-jointed tracks to be used in the place of wheels. The 5-ton tracks which are those at present available, are each 4 ft. 6 ins. tong by 1 ft. I in. wide, and the length in contact with the ground is 3 ft. 6 ins: The ground pressure being low, it would seem that the claim which is made for an exceptionally long life for the tracks will be justified. Sc far as I am aware, this is the first time that such tracks have been applied to vehicles other than prime movers. One of the outstanding advantages is that even on soft ground they do not form ruts, as often happens with wheeled equipment. Such tracks should have application to vehicles used in harvesting sugar cane and rice, or to trailers for hauling peat.

Special-purpose trailers, such as may be used for logging work and for many duties on oilfields, usually call for a more detailed specification, but invariably if the maker be told the nature of the work involved, he will, from experience, design a vehicle that will meet the operator's requirements.

The "pick-a-back " trailer is a model which has been exported in large numbers. It is so called because it is carried on the tractor on the return journey, or at any time when it is not itself hauling a load. Such trailers are used for timber haulage or for the transport of long pipes, and by carrying the trailer when running light the tractive unit can make much faster running times. British makers have given special attention to the free oscillation of wheel assemblies for work on rough ground, and to simplifying loading and unloading. A favourite method of mounting the wheels on multiwheeled trailers designed for carrying heavy indivisible loads is to arrange them in pairs on short oscillating axles. With four twin wheels in line, such a trailer can traverse the roughest ground without causing undue stress on the trailer frame.

Loading and unloading of these multi-wheeled trailers are sometimes simplified by arranging for the withdrawal of either the front or rear-wheel assemblies. In one make of trailer which is notable for its hydraulic suspension system, the frame can be lowered or raised by means of the same hydraulic system, thus dispensing with separate jacks.

In an ingenious self-loading semi-trailer, the frame is first uncoupled and the front end lowered to the ground by winch gear mounted on the forward end of the tractive unit. The tractive unit is then marneuvred so that it hacks on. to the rear of the semi-trailer, By using the winch gear the load can be drawn on to the semi-trailer, the floor of which acts as an easy ramp. With the load in position, the tractive unit then lines up for towing and again, using the winch gear, raises the forward end of the semitrailer on to the turntable.

Extensible pole trailers for timber haulage are popular at home and overseas, and as some designs incorporate over-run brakes, they can be attached to any type of towing vehicle. Over-run brakes on such a trailer would, of course, be illegal in Britain.

British manufacturers are not content to sit in their works and produce designs for overseas with sliderules. They go out and secure first-hand knowledge of the conditions in the countries to which their products are consigned. While I was making my inquiries, executives of most of the concerns were either overseas or had recently returned. One maker runs his own light aeroplane, which is used to maintain contact with customers in Europe. Such enterprise brings its own reward as reflected in export figures which show no sign of falling despite increasing competition from foreign makers.