MAN first with Intarders

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

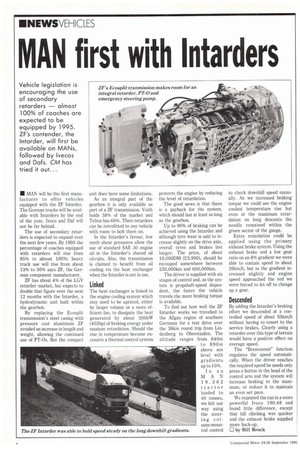

Vehicle legislation is encouraging the use of secondary retarders almost 100% of coaches are expected to be equipped by 1995. ZF's contender, the Intarder, will first be available on MANs, followed by lvecos and Dafs. CM has tried it out...

• MAN will be the first manufacturer to offer vehicles equipped with the ZF Intarder. The German trucks will be available with Intarders by the end of the year, Iveco and Daf will not be far behind.

The use of secondary retarders is expected to expand over the next few years. By 1995 the percentage of coaches equipped with retarders will rise from 85% to almost 100%; heavy truck use will rise from about 13% to 50% says ZF, the German component manufacturer.

ZF has about 4% of the LGV retarder market, but expects to double that figure over the next 12 months with the Intarder, a hydrodynamic unit built within the gearbox.

By replacing the Ecosplit transmission's steel casing with pressure cast aluminium ZF avoided an increase in length and weight, allowing the continued use of PT-Os. But the compact unit does have some limitations.

As an integral part of the gearbox it is only available as part of a ZF transmission. Voith holds 38% of the market and Telma has 60%. Their retarders can be retrofitted to any vehicle with room to bolt them on.

In the Intarder's favour, low teeth shear pressures allow the use of standard SAE 30 engine oil in the Intarder's shared oil circuits. Also, the transmission is claimed to benefit from oil cooling via the heat exchanger when the Intarder is not in use.

Linked

The heat exchanger is linked to the engine cooling system which may need to be uprated, either by larger volume or a more efficient fan, to dissipate the heat generated by about 300kW (402hp) of braking energy under maxium retardation. Should the rise in temperature become excessive a thermal control system protects the engine by reducing the level of retardation.

The good news is that there is a payback for the system, which should last at least as long as the gearbox.

Up to 90% of braking can be achieved using the Intarder and although tyre wear is said to increase slightly on the drive axle, overall tyres and brakes last longer. The price, of about 10,000DM (3,900), should be recouped somewhere between 230,000km and 650,000km.

The driver is supplied with six stages of control and, as the system is propshaft-speed dependent, the faster the vehicle travels the more braking torque is available.

To find out how well the ZF Intarder works we travelled to the Allgau region of southern Germany for a test drive over the 36km round trip from Lindenberg to Oberstaufen. The altitude ranges from 640m to 89 0 m above sea level with gradients up to 10%.

In an MAN 19.362 tractor loaded to 40 tonnes, we felt our way using the steering column-moun

to check downhill speed manually. As we increased braking torque we could see the engine coolant temperature rise but even at the maximum retardation on long descents the needle remained within the green sector of the gauge.

Extra retardation could be applied using the primary exhaust brake system. Using the exhaust brake and a low gear ratio on an 8% gradient we were able to contain speed to about 26km/h, but as the gradient increased slightly and engine speed approached the red we were forced to let off to change up a gear.

Descended

By adding the Intarder's braking effort we descended at a controlled speed of about 55km/h without having to resort to the service brakes. Clearly using a retarder over this type of terrain would have a positive effect on average speed.

The "Bremsomat" function regulates the speed automatically. When the driver reaches the required speed he needs only press a button in the head of the control arm and the system will increase braking to the maximum, or reduce it to maintain an even set pace.

We repeated the run in a more powerful Iveco 190.48 and found little difference, except that hill climbing was quicker and the exhaust brake supplied more back-up.

0 by Bill Brock