ROW

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

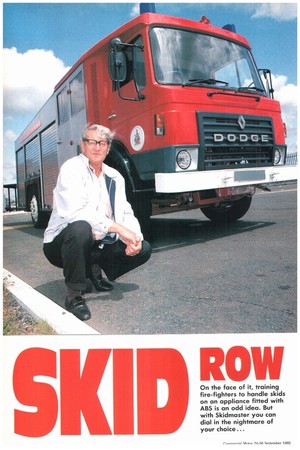

On the face of it, training fire-fighters to handle skids on an appliance fitted with ABS is an odd idea. But with Skidmaster you can dial in the nightmare of your choice...

• Skidding a heavy commercial vehicle is never something to be taken lightly. But when that vehicle is a fire appliance answering an emergency call any delay could have deadly consequences.

Training brigade drivers to handle skids is nothing new, but the Greater Manchester County Fire Service (GMCFS) has found a radical way of making that training realistic. It commissioned engineer and driving consultant John Tomlinson to equip a Dodge G13 fire appliance with his all-wheel-steer Skidmaster system.

"This vehicle cost us some £80,000," says GMCFS fleet manager Barry Martin, "but that is much cheaper than the £250,000 it would have cost us to build, let alone maintain, a skid pan. And don't forget that a new fire appliance costs around £90,000 and we've got 101 of them. If driver training on the Skidmaster saves us one write-off a year it will have more than paid for itself," Senior Technical Officer Jack Warren says that GMCFS intends to use the vehicle as part of its emergency fire appliance drivers' course. Along with car and large goods vehicle driver training it accounts for the 600 or so fire service drivers who pass through the training school at Leigh each year on novice or refresher courses.

SKID PAN

Cost is not the only reason why the GMCFS bought the Skidmaster.

According to instructor Colin Grimshaw: "A skid pan takes up a lot of room and its value is dependent on the skill of the driver".

His colleague Alan O'Neil explains: "On the skid pan, a driver who's 'lost it' doesn't know why he's lost it and can't experience exactly the same type of skid again and again. He can only learn by his mistakes over a long time. The Skidmaster allows you to repeat the same type of skid time and again, with or without the ABS operating, until the driver can recognise each skid type. Once he can recognise the skid immediately he can employ the right technique to regain control of the vehicle — and that can not only save money on accident damage, it can also save lives too."

To teach drivers to handle emergencies the Skidmaster doesn't have to skid. Instead it enables the instructor to deny the driver control of the vehicle. Providing the driver responds correctly the electronic control systems restore vehicle control automatically.

The Skidmaster gives a remarkably realistic illusion of rear wheel, front wheel or four-wheel skidding, all at less than 30km/h. The rear suspension is equipped with air bags which alternately inflate and deflate, depending which steering lock is applied. This reproduces body roll at low speeds and, at the touch of a button, the driver can experience the advantage of anti-lock brakes. This could not normally be done at low speeds on a dry surface.

The vehicle looks and drives exactly like a standard fire appliance. Apart from the electronic and mechanical modifications associated with the Skidmaster that's exactly what it is, right down to its 1,800litre water tank.

Commercial Motor tried the Skidmaster-fitted Dodge in action and while the rear wheel skid felt real enough, it was the front wheel skid which showed the dangers of trying to correct the steering before reducing the vehicle's road speed and eloquently illustrated the benefits of skid control training for all drivers of large CVs.

"Skidding is intimidating," says Tomlinson. "Most drivers would be far happier never to get into a skid in the first place and this, the recognition and prevention of skidding, is the purpose of Skidmaster."

The 11-tonne Dodge G13 appliance chassis is powered by a Perkins vee-eight 8.8-litre diesel driving through an Allison automatic gearbox. Ironically, the Dodge also has Girling ABS.

There is a drive/steering axle at the rear powered by an electro/hydraulic unit equipped with a four-valve block (two fast, two slow), The direction in which the steering wheel is turned determines which pair of the four valves operates to power the hydraulic ram. This in turn applies steering lock (rear wheel slide). The steering lock cancels out automatically when the front of the vehicle is in line with the rear.

FRONT LOCK

If the front lock is not cancelled out when the rear wheels come back to the straight ahead position the rear wheels will automatically turn in the opposite direction (secondary skid).

The front steering mechanism incorporates a hydraulic ram in place of the standard drag link. This ram is controlled by two progressive valves. Depending on the steering direction, the steering input is absorbed in a controlled way to produce the illusion of a front wheel skid (understeer).

lithe brake override button has been pushed the system will absorb all the steering input when the driver presses the brake. In addition, the ABS control valve has been instructed to dump air. The effect of this — no brakes or steering — is what happens when a driver locks his vehicle's brakes.

When the brake pedal is released the secondary ram will turn the road wheels to relate with the position of the steering wheel. This steering alignment is controlled by two linear potentiometers, as is the position of the rear wheels.

The technology is fascinating but, its purpose is simple: to get firefighters and equipment to an emergency as quickly, and as safely, as possible.

by Bob Little