THE PHOENIX OF GUILDFORD

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

When John Dennis left Hestair Dennis to set up John Dennis Coachbuilders it was the end of an era — and the start of another. His company is now flourishing in a tough sector.

• In 1985 the axe fell at Hestair Dennis's Woodbridge works. Some 400 jobs were lost when the Guildford plant ceased production of municipal vehicles and closed its fire engineering division. Municipal production was transferred to Hestair-Eagle at Warwick and Dennis Specialist Vehicles was set up to produce a range of fire appliance and PSV chassis.

The Dennis name has always been associated with fire engines but following the re-organisation, Dennis Specialist Vehicles announced that its fire engineering requirements would be contracted out to Carmichael at Worcester while just before the reorganisation John Dennis, who was coach and truck sales manager with Hestair Dennis, left the company to start his own engineering business. He was the company's last link with the original Dennis Brothers, so his departure marked the end of an era.

FIRE ENGINEERING

Once Hestair's Vehicle Division reorganisation was complete John Dennis was joined by 12 former Hestair Dennis employees who brought with them 292 years worth of coachbuilding and fire engineering experience. John Dennis had to get permission from the Hestair Group to use his own name for his company. That permission was initially refused, but in the event no objection was raised to the firm being called John Dennis Coachbuilders. The new company retained a close working relationship with Dennis Specialist Vehicles, and was soon engaged in warranty and remedial work on Dennis RS

Type B water tender fire appliances. This was followed by accident repair work and before long the first order was received for complete John Dennis fire engine bodies, putting to good use the body jigs and a pump test rig and tank that were acquired from the old Hestair Dennis plant.

REDUNDANCY MONEY

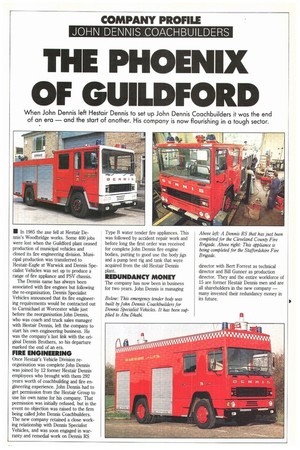

The company has now been in business for two years. John Dennis is managing Above left: A Dennis RS that has just been completed for the Cleveland County Fire Brigade. Above right: This appliance is being completed for the Staffordshire Fire Brigade.

director with Bert Forrest as technical director and Bill Gunner as production director. They and the entire workforce of 15 are former Hestair Dennis men and are all shareholders in the new company — many invested their redundancy money in its future. John Dennis Coachbuilders operates from a leased building in Merrow, on the outskirts of Guildford. It competes in a saturated market but, says John Dennis, by concentrating on high-quality products it is winning orders from a growing number of fire brigades.

MAJOR PRODUCERS

When Hestair Dennis dropped out of fire engine manufacture it had 65% of the market. Now each tender for new vehicles attracts an average of 14 bidders on a variety of chassis, including Dennis, Dodge, Volvo and Mercedes-Benz. Companies such as Saxon, HCB, Fulton and Wylie and AngloCo are all major producers of the mainstay of British firefighting: The Type B water tender. In addition the first imported bodies from Polyrna of West Germany are now in service.

Despite all this the company has full order books for new bodies from a number of brigades, including Staffordshire, Essex and Cleveland, and is also supplying complete fire engines to Dennis Specialist Vehicles. For example, a recent order was for an emergency tender destined for the Middle East, built on a Dennis RS chassis, and the company has even renovated a picnic trailer for the Royal Family.

CLOSE RELATIONSHIP

So far nearly all John Dennis bodies have been fitted to Dennis chassis, but despite the close relationship between the two companies, there is no financial link: John Dennis Coachbuilders is owned entirely by its directors and workforce. John Dennis himself is a realist, and is well aware that many fire brigades are looking at a variety of chassis for their appliances. The company has supplied a 4x4 Bedford-based water tanker to the Cambridge Fire and Rescue service and it is now working on a control unit body on an ERF dropframe chassis for the Staffordshire Fire Brigade. It also has orders for two emergency rescue tenders for Staffordshire, based on extended American Jeep chassis.

Forrest has designed a water tender body based on the Volvo FL6 chassis which is currently attracting interest among the brigades. Al] in all, the company is well placed to build on its early success. In 1985 it turned over 2750,000 — this year turnover looks set to top 21.2 million. In a market of about 250 water tender bodies per year, it has the capacity to produce up to 40 per year. Craft and quality are its main selling points: each body takes about eight weeks to complete. John Dennis-built vehicles get eight coats of paint and bodies are built using the best possible materials, says Dennis, including stainless steel. Most water tender bodies, by comparison, are of tubular steel with either embossed, unpainted or flat painted aluminium panelling. Standard equipment includes Godiva pumps and 1,5001it tanks.

SUCCESSFUL START

Despite the company's successful start, the question remains: is there still room for the small man in such a competitive market? Will cost-concious public authorities pay for high quality and craftsmanship? So far, the answer seems to be yes. John Dennis believes it can sustain its present size for the foreseeable future, with scope for expansion.

While fire appliances remain its core product, the company aims to offer other specialist vehicles such as television units, mobile workshops, control units and a range of racing transporters.

Next year, as well as standard water tenders, it will fit coachwork to Dennisbased turntable ladder appliances for the London Fire Brigade. It has even renovated an 1973 ex-Devon Fire Brigade Dennis D Series machine which will be used on an expedition from the North Cape of Norway to the South Cape of South Africa, designed to raise funds for the Samaritans.

by Noel Wilier